Focused Training Key For Industry

Is the pandemic over? Some days it’s difficult to tell, as the ripple effects of continued cases of COVID-19 continue to pop up and create problems for both workers and manufacturers. Although the severity of pandemic-related disruptions has certainly subsided, industries around the world are still struggling with the aftershocks of a tumultuous few years.

In addition to ongoing supply chain woes, manufacturers are also contending with a labor marketplace that has changed fundamentally as a result of the pandemic. Prior to the pandemic, industry was struggling to fill open positions with qualified workers. Today, these struggles remain and in many areas have gotten even worse.

As a result, industries are placing a great emphasis on skills assessment to ensure that new hires can hit the ground running. In addition, upskilling current employees has taken on new significance, as industries seek to make the most of available human resources when it’s difficult to hire qualified new workers.

In this article, we’ll take a look at the current skills gap, the type of skills assessment and training that industry needs, and how the training tools offered by DAC Worldwide can help employers and instructors assess and train workers for the jobs of today and tomorrow.

How Wide is the Skills Gap?

Now that the worst of the pandemic appears to be behind us, things should be slowly getting better, right? Why then do manufacturers seem to be falling farther behind? According to an article by Alexandra Johnson:

“Before COVID, the situation was bad, but post-pandemic it has become even worse. Despite lockdown lifting, the industry is reporting over 515,000 jobs need filling, just to meet demand.”

Commonly known as the “skills gap,” there remains a sizeable disparity between the supply of highly-skilled workers and the demand for these workers in today’s industrial labor market. In fact, experts predict the skills gap is going to get even worse in the foreseeable future.

A study conducted by Deloitte for the Manufacturing Institute estimates that, over the next decade, almost 4.6 million manufacturing jobs will need to be filled. However, because of the skills gap, as many as 2.4 million — more than half! — of those jobs could go unfilled.

In a recent Forbes article, author Graham Glass notes that “[n]early half (46%) of learning and development (L&D) leaders say the skills gap is widening in their organization, and 49% say executives are concerned employees don’t have the right skills to execute business strategy, per findings from LinkedIn Learning’s ‘2022 Workplace Learning Report.’”

What is industry to do? Glass advises that “organizations need to emphasize employee upskilling, reskilling and right-skilling — and anticipate the skills employees need to succeed in their positions…By assessing the business’s needs pre-training (to develop training content) and post-training, companies can work to bridge skills gaps and create training programs that are impactful and useful to employees and the organization alike.”

Skills-Based Hiring

What’s the best approach for industry to take to bridge the skills gap? Should industry simply hire anyone they can get their hands on and then train them to do the jobs they need done? For many reasons, that strategy is probably not the best solution.

Industry is already struggling with a host of issues left over from the pandemic. Most companies don’t have the bandwidth to babysit new workers while they acquire the training they need. Many also don’t have either the personnel or the tools to effectively train new workers.

That’s why, in an article in the Harvard Business Review, LinkedIn CEO Ryan Roslansky advocates for a new skills-based approach to hiring. Roslansky urges employers to “[f]ocus on the results you’d like to see, rather than the type of qualifications that you think could deliver them. Highlighting the desired skills — the candidate’s ability to perform certain tasks — gets to the same results without creating an unnecessary barrier to entry, like a requirement for a four-year degree.”

In an article by Adina Miron, the author agrees:

“Skills-based hiring enables employers to hire for the skills gaps that exist within their organization. Rather than focusing on experience, education, or certifications, companies should focus on identifying candidates with the needed skills to fill open positions.”

Roslansky echoes these thoughts:

“Shifting to a skills-focused approach is a viable solution to an evolving workforce dilemma…Stay focused on skills — and the assessments that can measure them…there are plenty of ways to gauge a candidate’s ability to perform without relying on their education or experience as proxies.”

How do employers shift to a skills-based hiring approach? Unfortunately, generalized assessments and comprehensive training systems can be difficult to use in the context of hiring new workers in industry. Why? The answer can be found in the concept of specialization of labor.

According to an article by Sampson Quain:

“Specialization of labor…refers to a process in business in which large tasks are divided into smaller tasks, and different employees or different groups of employees complete those tasks. Specialization is highly desirable in large-scale operations such as…manufacturing because it allows workers with specific skill sets to efficiently perform a specific task.”

For example, a manufacturer may need to hire someone with a specific skillset related to the operation, maintenance, troubleshooting, and repair of mechanical belt drives. A prospective candidate might claim to have general mechanical knowledge and skills, but how can the employer know whether the worker has the specific belt drive skills it needs?

To effectively use a skills-based hiring approach in manufacturing, employers need focused assessment and training tools that can be used to adequately determine a potential worker’s skills in a very specific area.

Training at the Speed of Industry

Industry must also dedicate resources to ongoing training for current workers. The need for ongoing training is real and cannot be ignored. Industries today need to attack the skills gap with a combination of skills-based hiring and instituting training of current workers that is practical and effective.

In his Forbes article, Glass argues that “a personalized approach to training can also be useful to employees and companies.” However, he acknowledges that, “[i]n large companies, especially, creating individualized learning paths manually can be time- and resource-intensive.” He also points out that “employees need training that fits into their workflows.”

Most companies cannot afford the luxury of sending workers off-site for a week or more at a time for in-depth training. Instead, they need focused, skills-based training that allows workers to obtain the hands-on skills they need while minimizing the effect on production of time away from the workplace.

Fortunately, a variety of training tools exist that can offer industries time-saving, cost-effective solutions for focused skills assessment and hands-on training. In the next section, we’ll take a closer look at DAC Worldwide’s range of single-topic trainers that can help industry move to a skills-based hiring model and also upskill current employees.

DAC Worldwide Offers Focused Assessment & Training Tools

DAC Worldwide offers training systems for a variety of industry sectors, including advanced manufacturing, process/chemical manufacturing, marine, military, oil and gas, and power generation. These training systems also cover many different technical topics, such as electrical and electronics; heat transfer and steam; mechanical drives; oil production; process control and instrumentation; and pumps, compressors, and valves.

Rather than broad-based training in multiple areas, DAC Worldwide’s training systems provide hands-on training focused on specific tasks. This makes them particularly helpful to employers for skill assessment (either pre-employment or for upskilling purposes). For example, DAC Worldwide offers training systems targeted specifically at key mechanical maintenance skills:

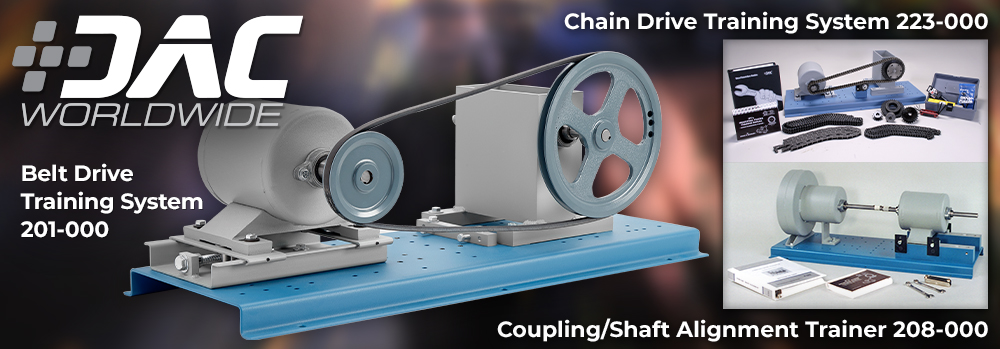

Belt Drive Training System

The Belt Drive Training System (201-000) allows for convenient assessment and training in the identification, installation, tensioning, and alignment of common belt drives types found in industry. Featuring hardware for applications related to multiple matched belts, fractional horsepower belts, positive drive belts, and variable pitch sheaves, the system provides a variety of training and assessment applications in one benchtop piece of equipment.

Coupling/Shaft Alignment Trainer

The Coupling/Shaft Alignment Trainer (208-000) allows for realistic training and assessment in shaft alignment. Designed based on the dimensions of a common ANSI centrifugal pump, this trainer can assess and train workers on all common alignment techniques and tools. Training and assessment topics include using a dial indicator in coupling/shaft alignment, the reverse dial indicator method, fabrication of shaft keys, and installing a flexible disc coupling.

Chain Drive Training System

The Chain Drive Training System (223-000) allows for in-depth assessment and training in industrial chain drives, heavy/silent chains, and sprocket set usage. Using industry-standard components workers will encounter on the job, this training system provides a complete training and assessment experience covering topics such as taper lock bushings, chain drive maintenance, installation/alignment of chains, and tensioning of chains.

Let DAC Worldwide Help You Fill Your Skills Gaps

The mechanical assessment and training tools highlighted above are just a few examples of the variety of technical training tools DAC Worldwide manufactures. In addition to training systems, DAC Worldwide also offers a wide range of industrial cutaways, detailed scale models, and sample boards featuring industrial components.

Contact a consultant with DAC Worldwide today to learn more about how their technical training tools can help you build the assessment and training program your company needs. Using DAC Worldwide training and assessment tools, you can transition to a skills-based hiring approach and fill the skills gaps in your organization!

About Duane Bolin

Duane Bolin is a former curriculum developer and education specialist. He is currently a Marketing Content Developer in the technical training solutions market.

- Published in News

Focused Assessment Key to Finding Workers with the Right Skills

Click HERE to view Focused Assessment Key to Finding Workers with the Right Skills as a multimedia presentation.

“Now Hiring!”

These days, it seems like it doesn’t matter what type of business you’re in. If your business is open, then it probably has one of these signs in the window.

As industries across every sector continue to navigate the ups and downs of an uneven economic recovery in the wake of the ongoing COVID-19 pandemic, hiring managers are struggling to fill open positions.

Whether you’re an employer looking to fill critical roles or an instructor trying to prepare your students for available jobs, it’s important to understand that now, more than ever, workers need the right skills to be successful in the modern industrial workplace.

In this article, we’ll take a look at the issues employers face trying to find workers with the right skills. We’ll also explain the importance of focused assessment and how the training tools offered by DAC Worldwide can help employers and instructors assess and train workers for the jobs of today and tomorrow.

Why are there so many Open Manufacturing Jobs?

The COVID-19 pandemic took a heavy toll on manufacturers. Combining fluctuating demand with quarantining workers and vast supply chain disruptions, many manufacturers struggled to weather the many storms they faced.

The COVID-19 pandemic took a heavy toll on manufacturers. Combining fluctuating demand with quarantining workers and vast supply chain disruptions, many manufacturers struggled to weather the many storms they faced.

Now that we’re in an extended period of uncertain recovery, things should be slowly getting better. After all, unemployed people do need jobs, right? Instead, manufacturers seem to be falling farther behind.

According to an article by Alexandra Johnson:

“The US manufacturing industry is forecast to grow 7% in 2021, yet with this anticipated growth, the industry is struggling to hire enough workers to meet demand. Before COVID, the situation was bad, but post-pandemic it has become even worse. Despite lockdown lifting, the industry is reporting over 515,000 jobs need filling, just to meet demand.”

Why are so many manufacturers having such a hard time filling their many open positions? Experts believe that a big part of the problem is that too many workers simply don’t possess the skills employers need.

Today’s manufacturing workplace isn’t the dirty, boring, repetitive assembly line some people erroneously imagine. Modern facilities feature cutting-edge technologies that require specialized skills that not enough workers seem to have these days.

How can Manufacturers find Workers with the Right Skills?

With so many open positions to fill, it might seem like manufacturers should simply hire anyone they can get their hands on and then train them to do the jobs they need done. This approach, however, isn’t advisable for a variety of reasons.

Primarily, manufacturers who are already struggling with a whole host of issues don’t have the bandwidth to babysit new workers while they acquire the training they need. Many manufacturers also don’t have either the personnel or the tools to effectively train new workers.

In an article in the Harvard Business Review, LinkedIn CEO Ryan Roslansky advocates for a new skills-based approach to hiring. Roslansky argues that a skills-based approach “is the future of hiring and development…At a time when talent is the number-one commodity in business, companies can’t afford to remain stuck in old mindsets.”

Roslansky urges employers to “[f]ocus on the results you’d like to see, rather than the type of qualifications that you think could deliver them. Highlighting the desired skills — the candidate’s ability to perform certain tasks — gets to the same results without creating an unnecessary barrier to entry, like a requirement for a four-year degree.”

In an article by Adina Miron, the author agrees:

“Skills-based hiring enables employers to hire for the skills gaps that exist within their organization. Rather than focusing on experience, education, or certifications, companies should focus on identifying candidates with the needed skills to fill open positions.”

Roslansky echoes these thoughts:

“Shifting to a skills-focused approach is a viable solution to an evolving workforce dilemma…Stay focused on skills — and the assessments that can measure them…there are plenty of ways to gauge a candidate’s ability to perform without relying on their education or experience as proxies.”

A Skills-Based Hiring Approach Requires Proper Assessment & Training Tools

The nature of manufacturing makes generalized assessments and comprehensive training systems difficult to use in the context of hiring new workers. Why? The answer can be found in the concept of specialization of labor.

The nature of manufacturing makes generalized assessments and comprehensive training systems difficult to use in the context of hiring new workers. Why? The answer can be found in the concept of specialization of labor.

According to an article by Sampson Quain:

“Specialization of labor…refers to a process in business in which large tasks are divided into smaller tasks, and different employees or different groups of employees complete those tasks. Specialization is highly desirable in large-scale operations such as…manufacturing because it allows workers with specific skill sets to efficiently perform a specific task.”

For example, a manufacturer may need to hire someone with a specific skillset related to the operation, maintenance, troubleshooting, and repair of mechanical belt drives. A prospective candidate might claim to have general mechanical knowledge and skills, but how can the employer know whether the worker has the specific belt drive skills it needs?

To effectively use a skills-based hiring approach in manufacturing, employers need focused assessment and training tools that can be used to adequately determine a potential worker’s skills in a very specific area.

DAC Worldwide Offers Focused Assessment & Training Tools

Employers don’t need to recreate the wheel to move toward a skills-based approach to hiring. DAC Worldwide, an industry-leading manufacturer of technical assessment and training tools, offers a variety of solutions to the problems employers face.

In this section, we’ll take a closer look at several of DAC Worldwide’s focused assessment and training tools that employers can use to effectively and efficiently ensure that they’re hiring workers with the skills they need.

Belt Drive Training System (Model: 201-000)

Belt Drive Training System (Model: 201-000)

The Belt Drive Training System allows for convenient assessment and training in the identification, installation, tensioning, and alignment of common belt drives types found in industry. Featuring hardware for applications related to multiple matched belts, fractional horsepower belts, positive drive belts, and variable pitch sheaves, the system provides a variety of training and assessment applications in one benchtop piece of equipment.

Coupling/Shaft Alignment Trainer (Model: 208-000)

The Coupling/Shaft Alignment Trainer allows for realistic training and assessment in shaft alignment. Designed based on the dimensions of a common ANSI centrifugal pump, this trainer can assess and train workers on all common alignment techniques and tools. Training and assessment topics include using a dial indicator in coupling/shaft alignment, the reverse dial indicator method, fabrication of shaft keys, and installing a flexible disc coupling.

Chain Drive Training System (Model: 223-000)

The Chain Drive Training System allows for in-depth assessment and training in industrial chain drives, heavy/silent chains, and sprocket set usage. Using industry-standard components workers will encounter on the job, this training system provides a complete training and assessment experience covering topics such as taper lock bushings, chain drive maintenance, installation/alignment of chains, and tensioning of chains.

Let DAC Worldwide Help You Fill Your Skills Gaps

Let DAC Worldwide Help You Fill Your Skills Gaps

The mechanical assessment and training tools highlighted above are just a few examples of the variety of technical training tools DAC Worldwide manufactures. In addition to training systems, DAC Worldwide also offers a wide range of industrial cutaways, detailed scale models, and sample boards featuring industrial components.

Contact a consultant with DAC Worldwide today to learn more about how their technical training tools can help you build the assessment and training program your company needs. Using DAC Worldwide training and assessment tools, you can transition to a skills-based hiring approach and fill the skills gaps in your organization!

- Published in News

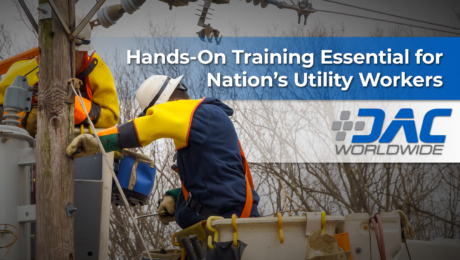

Hands-On Training Essential for Nation’s Utility Workers

Click HERE to view Hands-On Training Essential for Nation’s Utility Workers as a multimedia presentation.

Do you ever daydream about going “off the grid”? For many, the thought of unplugging for an extended time away from life’s troubles sounds refreshing.

The reality underlying this common dream of escape is how thoroughly tied our lives are to the grid. What would our everyday routines be like without the utilities we so often take for granted?

We don’t give them much thought until Mother Nature intervenes with a foot of snow or an ice storm. When the lights go out, the Internet stops streaming, water freezes in the pipes, and furnaces quit heating, we think about nothing but our precious utilities until they return.

The unsung heroes in these situations are the nation’s frontline utility workers that must brave the elements to do their jobs in the worst circumstances. We wait anxiously and depend upon their expertise and dedication to restore our lives back to normal.

One day soon, though, we could find that wait lasting longer and longer. Why? Our nation’s utilities are facing an unprecedented — and worsening — shortage of workers with the skills necessary to keep the grid functional.

In this article, we’ll take a closer look at the looming shortage of utility workers across the country. We’ll also examine how one training center in Kansas is addressing the issue. Finally, we’ll discuss easy-to-use training options that any utility can use to provide safe, hands-on skills training to their frontline workers.

The Power & Utilities Skills Gap

Industries of all kinds across the nation are facing a critical shortage of skilled workers, and the power and utility industries are no exception. Demand for workers in these industries remains strong, but finding new workers to replace the many workers ready to retire is proving to be a substantial challenge.

Industries of all kinds across the nation are facing a critical shortage of skilled workers, and the power and utility industries are no exception. Demand for workers in these industries remains strong, but finding new workers to replace the many workers ready to retire is proving to be a substantial challenge.

In an Energy Central article, author Karen Marcus notes:

“As older workers retire, many utilities are finding it difficult to replace them, and to attract employees with the skills needed to advance a 21st century industry. According to T&D World, Airswift and Energy Jobline found in a survey of over 17,000 professionals that ‘48 percent of power professionals are concerned about an impending talent emergency, with 32 percent believing the crisis to have already hit the sector and 38 percent reporting that their company had been affected by skills shortages.’”

The shortage of skilled workers is real, and experts predict it’s only going to get worse in the future. According to Marcus:

“The U.S. Department of Energy (DoE) Quadrennial Energy Review (QER) reports that, according to one study, the industry will ‘need 105,000 new workers in the smart grid and electric utility industry by 2030, but expects that only 25,000 existing industry personnel are interested in filling those positions.’ The remaining 80,000 employees in this supply-demand mismatch will need to be filled through recruiting and training. However, the industry is not expected to meet the forecasted need with its current recruitment and training rates.”

Obviously, something needs to change. As the DoE QER states, “Industry hiring managers often report that lack of candidate training, experience, or technical skills are major reasons why replacement personnel can be challenging to find.”

If the power and utilities skills gap is to be bridged, utility companies must find a way to effectively provide safe, hands-on training to equip current and future workers with the critical skills they need to fill frontline positions as quickly as possible. Fortunately, solutions are available, and in the next section we’ll examine an exemplary approach taken by an association of municipal utilities in Kansas.

A Training Pioneer

Nearly two decades ago, Kansas Municipal Utilities (KMU), an association of more than 100 public utilities across the state of Kansas, recognized a dire need to effectively train the next generation of field workers. The groundbreaking solution KMU pioneered was finally brought to life a few years ago in the form of a $3.2 million training center.

Nearly two decades ago, Kansas Municipal Utilities (KMU), an association of more than 100 public utilities across the state of Kansas, recognized a dire need to effectively train the next generation of field workers. The groundbreaking solution KMU pioneered was finally brought to life a few years ago in the form of a $3.2 million training center.

As author Rick Aguilar notes in a T&D World article, KMU’s 20,000-square-foot training facility was seen as “a way to short-circuit the learning curve so utilities could swiftly prepare new hires to work as effective front-line employees.”

KMU’s training center allows for safe year-round training. Not only does the facility feature dozens of wood poles, but it also boasts a variety of industrial-grade components to create the most realistic distribution system possible.

For utility workers, real-world, hands-on training is essential. As Aguilar notes in his article:

“Because safety is an integral part of all utility work, the new training center helps the students learn through hands-on instruction. While they can pick up on key knowledge through sitting in class and reading books, the real rubber meets the road when they are actively participating in hands-on learning.”

For example, KMU’s training center allows workers “to get hands-on training in a controlled environment…[that] mitigates some of the hazards inherent in utility work, and it allows the field workers to make mistakes in a safe environment.”

KMU has found that a combination of classroom work and hands-on training is the ideal training experience. “For example, if KMU offers a workshop on transformer theory and connections, then the linemen can get hands-on experience immediately after they receive classroom instruction to connect their learning to actual work.”

Training Solutions for Everyone

As Aguilar notes in his article, “[m]any of the members of KMU are small in scope, and as such, they don’t have the ability to provide a comprehensive training program or build a facility of their own.” That’s why the KMU training center is such an important and valuable resource for Kansas utilities.

As Aguilar notes in his article, “[m]any of the members of KMU are small in scope, and as such, they don’t have the ability to provide a comprehensive training program or build a facility of their own.” That’s why the KMU training center is such an important and valuable resource for Kansas utilities.

Nevertheless, “every utility needs to have a safe, qualified workforce.” So what are utilities in other states without the benefit of a KMU training facility supposed to do? Fortunately, there are a variety of training solutions that offer any utility the ability to provide critical hands-on skills training.

For example, DAC Worldwide manufactures a variety of unique training systems and industrial component cutaways that teach the essential hands-on skills frontline utility workers need most. In this final section, we’ll learn more about how utilities can use these systems to meet their training needs.

Transformer Wiring Training System (408-000)

DAC Worldwide’s Transformer Wiring Training System (408-000) is a realistic training device that replicates the conditions and circumstances that a utility worker encounters when making common power transformer connections in the field. This convenient tabletop training system provides hands-on training without the danger of full-voltage field experience.

DAC Worldwide’s Transformer Wiring Training System (408-000) is a realistic training device that replicates the conditions and circumstances that a utility worker encounters when making common power transformer connections in the field. This convenient tabletop training system provides hands-on training without the danger of full-voltage field experience.

For example, a 208VAC, three-phase source is stepped down, creating a 41VAC, three-phase system. The training system includes two complete sets of three-phase transformers so that paralleling can be explored. Users will also get first-hand experience using banana jacks, ground/primary connections, and secondary connections using both three-phase and single-phase applications.

Learners will study topics like analyzing transformer single-phase/three-phase voltages, identifying transformer turns ratio (TTR), and demonstrating how connections can produce incorrect motor rotation. They will also practice hands-on skills, such as performing transformer connections, interconnecting multiple transformers in Wye or Delta configurations, and simulating a burned-out transformer in a three-phase bank.

Transformer Connections Training System (491-000)

DAC Worldwide’s Transformer Connections Training System (491-000) teaches the key skills that a utility worker must master in order to confidently operate modern generating equipment, such as the paralleling of generators and connecting to a larger power grid. The system replicates the conditions and circumstances utility workers encounter when making common transformer connections in the field.

For example, learners can practice ground connections, primary connections, and secondary connections easily using banana jacks. Both three-phase and single-phase applications are provided, and a 208 VAC, 3-phase source is stepped down to a 41 VAC, 3-phase system for safety.

Users will find that the Transformer Connections Training System provides a safe and efficient, yet realistic alternative to a full-voltage field experience. Standard accessories include patch cords, fourteen (14) transformers, a panel-mounted voltmeter and phase rotation meter.

Industrial Transformer Cutaways

DAC Worldwide’s Single-Phase Transformer Cutaway (273-912) and Three-Phase Transformer Cutaway (273-915) are detailed, professionally-crafted transformer cutaways that depict a shell-type, single-phase transformer and a coaxially-wound, three-phase, delta-wye wired transformer, respectively.

DAC Worldwide’s Single-Phase Transformer Cutaway (273-912) and Three-Phase Transformer Cutaway (273-915) are detailed, professionally-crafted transformer cutaways that depict a shell-type, single-phase transformer and a coaxially-wound, three-phase, delta-wye wired transformer, respectively.

Through careful sectioning, the complete internal configurations of these transformers can be seen. Details shown include the laminated steel core, primary and secondary windings, and primary insulation.

Common transformer brands and models are chosen for sectioning for industrial relevance. Users will gain valuable insight into the inner workings of these transformers that they will encounter on a regular basis in the field.

- Published in News

New Marine Corps Doctrine Promotes Education & Training

Click here to view New Marine Corps Doctrine Promotes Education & Training as a multimedia presentation.

The few. The proud. Who are we talking about? The Marines, of course. That particular recruiting slogan has been permanently etched into our memories over the years.

And it’s a great slogan. The Marines are legendary for a training regimen that weeds out all but the strongest, creating a fighting force to be reckoned with. Indeed, the Marines have been on the front lines of every major U.S. military campaign of the modern era.

To be prepared for the future, however, the Marines know that training the same way they have in the past will not be sufficient. That’s why a recent doctrinal publication puts a new focus on education and continued learning.

Industry, always closely connected to the military, would do well to put a renewed emphasis on education and training, too. In this article, we’ll take a closer look at how partnering with a trusted technical training company like DAC Worldwide can prepare your students, workers, soldiers, and sailors for a bright future.

A New Doctrine for a New Era

According to a Marine Corps Times article, “the Marine Corps unveiled the Marine Corps Doctrinal Publication 7 [MCDP 7] in February [2019] as the service aims to promote education, training, and continued learning among Marines so they become students of their profession.”

According to a Marine Corps Times article, “the Marine Corps unveiled the Marine Corps Doctrinal Publication 7 [MCDP 7] in February [2019] as the service aims to promote education, training, and continued learning among Marines so they become students of their profession.”

How significant was this doctrinal development? MCDP 7 was the first new doctrinal publication issued by the Marines since 2001. Its goal: “to motivate Marines to personally assess where they can improve and understand the ‘why’ behind the significance of learning.”

Maj. Gen. William Mullen was quoted as saying “that he’s heard Marines say they joined the service to escape an academic education. But the Corps wants its personnel to understand that the two complement one another and that education prepares Marines to think quickly when faced with challenges.”

According to Mullen, “You need both training and education. Training prepares you for things you know you’re going to have to do…But the education piece comes in when the unknown starts to happen, which it always does.” Mullen specifically referred to the fact that the environments Marines face today present challenges that are only growing more complex.

This new doctrinal change comes as “Commandant of the Marine Corps Gen. David Berger is working to remake the Corps to better compete with potential high-end adversaries…Berger wants a leaner force to conduct sea denial operations, survive in a contested maritime environment and serve as a larger Naval expeditionary force.”

It’s Not Just the Marines

It’s Not Just the Marines

Speaking of the Navy, the Marine Corps Times article notes that the Navy announced in May 2019 “that it was modifying fitness reports to reflect an individual’s educational and training accomplishments, including military education courses, professional and academic certifications, among other things.”

Like the Marines’ new focus on education and continued learning, the Navy’s modified fitness reports are meant to “show that career-long military learning isn’t only job-related technical or tactical training, and that a commitment to higher education will produce Navy leaders with more refined critical thinking skills,” according to an article in the Navy Times.

Future Navy fitness reports will thus document educational performance, including “[m]ilitary educational courses, civilian institution coursework, and professional and academic certifications.” Navy leadership also indicated they will also encourage additional informal efforts, such as learning new technologies.

It’s All COOL

It’s All COOL

It’s no coincidence that the Marines and the Navy would emphasize professional and academic certifications. Much of the training that military personnel receive prepares them for future civilian jobs.

Obtaining professional and academic certifications while in the military can make it easier for personnel to transition to civilian life when their service is finished. All branches of the military recognize the importance of certifications in making that transition as easy as possible.

For example, the Marine Corps COOL site (Marine Corps Credentialing Opportunities On-Line) helps Marines see how their military training and experience matches up with civilian credential requirements. Such credentials could include important and valuable advanced manufacturing credentials from entities like the National Institute of Metalworking Skills (NIMS) and the Manufacturing Skill Standards Council (MSSC).

Marines using the COOL site can see whether military funding is available to help attain particular credentials. They can also see how the training and skills they’ve already acquired might match up with specific credentials valued by employers, such as NIMS’ Industrial Technology Maintenance (ITM) certification or MSSC’s Certified Production Technician (CPT) certification. There are also COOL sites for the Army, Coast Guard, Navy, and Air Force.

Industry Must Also Evolve

Industry Must Also Evolve

Given the military’s new focus on education and continued learning, it’s important that industries that work with and support the military evolve in a similar fashion. The military-industrial complex consists of all sorts of industries that work closely with the military to help them accomplish their mission.

These industries should take a cue from their military counterparts and begin to develop a similar focus on education and continued learning among their workforce. Industry workers will only be able to continue to keep pace with their military counterparts if they’re also seeking new educational opportunities and learning new skills and technologies.

Pushing an industrial workforce or a military organization toward more education and greater skill development can be a daunting task. That’s why it’s imperative that both the military and their industrial counterparts seek out and rely upon the expertise of a trusted technical training partner.

A Trusted Education & Training Partner

DAC Worldwide is a US-based world leader in technical training solutions. For over 35 years, DAC Worldwide has been helping industrial employers and military organizations with realistic, hands-on training systems.

DAC Worldwide offers a wide range of product solutions to fit all your training needs. From training systems that teach a full range of skills to cutaways that increase understanding of how a component works, we have what you need.

For example, many military personnel work in the same skilled occupations as civilians. This means they need a solid foundation in various technologies, including electrical, electronics, fluid power, and mechanical drives.

Whether you train military personnel working on military bases or civilian crews with military contracts, DAC Worldwide’s military training solutions offer an unmatched range of products to allow you to create the course you need or to fill in any gaps that you have in your current training.

Let’s take a closer look at four specific DAC Worldwide products that can take your training program to the next level:

Lock-Out/Tag-Out Training System (811-000)

DAC Worldwide’s Lock-Out/Tag-Out Training System features a realistic, simulated working process environment that facilitates introductory training with hands-on activities related to the process of identifying and locking out sources of dangerous potential energy in an industrial setting. The training system includes two process tanks; a centrifugal pump; a complex, multi-purpose piping network; electrical controls; a variety of lockable system components; and a lock-out/tag-out kit that features a large number of commonly-encountered locking and tagging devices.

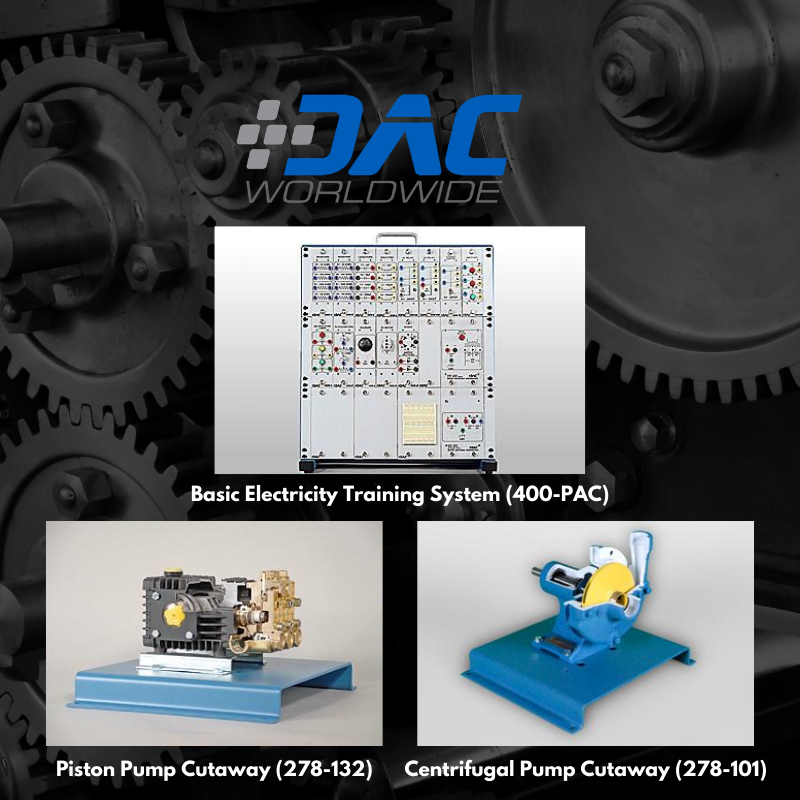

Basic Electricity Training System (400-PAC)

Basic Electricity Training System (400-PAC)

DAC Worldwide’s Basic Electricity Training System teaches basic AC and DC electrical principles. Learners will explore how electricity is used for power and control in various sectors. The trainer covers industry-relevant skills, such as installing, operating, and troubleshooting AC and DC electrical circuits in a variety of applications.

Piston Pump Cutaway (278-132)

DAC Worldwide’s Piston Pump Cutaway is an industrial piston pump that has been carefully sectioned and color-coded to train learners in the design, operation, construction, and maintenance of this common process pump used throughout industry. The cutaway exposes and showcases the complete internal configuration of an industrial piston pump. Moreover, seal features and bearings have been retained to allow realistic, hands-on pump maintenance and operation training.

Centrifugal Pump Cutaway (278-101)

DAC Worldwide’s Centrifugal Pump Cutaway is a sectioned centrifugal pump that provides realistic training in the operating principles, construction details, and maintenance of common centrifugal process pumps used throughout industry and the military. It includes various sectioned components, such as seals and bearings, as well as showcasing the pump’s impeller.

Contact DAC Worldwide Today

Is your organization ready to take its industrial technical training to the next level? Contact a DAC Worldwide expert today for a personal consultation regarding your training needs and how our variety of training systems, cutaways, dissectibles, and models can prepare both industrial workers and military personnel for the future challenges they face.

- Published in News

Bridging the Oil and Gas Skills Gap: Effective Technical Training for Current and Future Employees

Click HERE to view Bridging the Oil and Gas Skills Gap: Effective Technical Training for Current and Future Employees as a multimedia presentation.

Click HERE to view Bridging the Oil and Gas Skills Gap: Effective Technical Training for Current and Future Employees as a multimedia presentation.

What does 2020 and the coming years hold for industries around the globe? That’s the question on the minds of many executives as they embark on a new year and a new decade. For the oil and gas industry, a skills gap will continue to create problems for employers looking to seize new opportunities for increased efficiency and profitability. Effective technical training for current and future employees will be a key strategy necessary to solve this problem.

In this article, we’ll take a closer look at what 2020 holds for the oil and gas industry, including the reasons behind and current state of the skills gap in the industry. We’ll consider how companies are using training programs to upskill current workers and ensure future workers have the skills they need. Finally, we’ll look at how DAC Worldwide’s unique oil and gas training tools can help employers and educators to bridge the skills gap facing the oil and gas industry.

2020: Opportunities and Challenges

The oil and gas industry has rebounded from the economic downturn experienced several years ago. According to Deloitte’s 2020 Oil, Gas, and Chemical Industry Outlook, there are several reasons for optimism in the new year: “Liquid natural gas (LNG) keeps growing…[f]ossil fuel consumption is expected to continue to grow…[and] [g]lobal…oil supply remains secure thanks to growing US production and healthy stocks.”

The Deloitte report concludes that oil and gas executives need to be “ready to embrace new opportunities for profitable growth…Thanks to the lessons learned from the most recent boom and bust cycle, the industry is better equipped to face the future than it has been at any other point in the past decade. Still, there are fundamental, long-term challenges that they will have to face.”

The 2019 Global Energy Talent Index (GETI) Report agrees, noting that “[t]he oil price has rebounded and new projects are on the rise. The challenge now for the sector is to ensure that the talent supply can keep up with demand.” Why? Quite simply, “[m]aintaining a pipeline of new talent has become a challenge for oil and gas companies.”

The Oil and Gas Skills Gap

A recent Energy Sourcing article notes that, in the coming decade, the “U.S. Bureau of Labor Statistics expects 54.8 million total job openings [in the oil and gas industry],” but there are “not enough skilled people to fill them.” What is behind this skills gap? Experts point to a variety of factors that have contributed to the growing shortage of skilled talent in the oil and gas industry.

Too Few Millennials, Too Many Boomers

According to the 2019 GETI Report, “the impact of economic cycles on job stability is a leading cause of the skills shortage.” During the recent economic downturn, jobs were cut and recruitment efforts were severely curtailed. The result has been the slowing of “[t]he influx of young talent into the sector,” leading to the present “talent crunch.”

Now that the industry is back on the upswing, employers are trying once again to attract young talent, but they’re finding it’s not as easy as it used to be. As a recent Airswift article notes, oil and gas employers are learning a hard lesson: “The skills gap is a problem that money alone can’t solve.”

Not only is oil and gas “the number-one industry millennials wished to avoid working in because of its image,” but competition for young, skilled talent is fierce because the skills gap affects nearly every industry around the world.

Adding to the problem of the short supply of young talent is the fact that “[o]lder workers from the Baby Boomer generation are beginning to reach retirement age, ultimately heading off and taking decades of knowledge and experience with them.” Who will replace them?

Industry 4.0 Changes

Industry 4.0 Changes

Whoever does replace retiring workers will have to possess a stronger technical skillset than ever before. In addition to skills specific to the oil and gas industry, they will need advanced technological skills that will enable them to succeed as the industry experiences the dramatic changes characteristic of the Fourth Industrial Revolution, otherwise known as Industry 4.0.

Industries across the board and around the world are being impacted greatly by Industry 4.0’s technological advances. Oil and gas is no exception. As the Airswift article notes, “oil and gas companies are collecting more and more digital data which is helping to improve worker safety, monitor reservoir behaviour, plan ahead for smoother digs, maintain hardware and much more.”

They’re also incorporating new technologies, such as drones. According to the Oil and Gas Drone Services Market – Growth, Trends, and Forecast (2019-2024), the market for drone services in the oil and gas industry is expected to grow by more than 60% in the next five years.

As a Business Wire article summarizing the drone forecast notes, “[d]rones are being used for inspection to determine any damage or corrosion and to provide data for structural integrity and visual and infrared photography,” as well as for “pipeline inspection, corrosion checks, security checks, and maintenance issues.”

Positions Aplenty

Positions Aplenty

In addition to new positions, such as drone pilot and drone fleet manager, the oil and gas industry features a wide range of high-priority roles impacted by the skills gap. According to a recent study by RAND Corporation, the sector needs plenty of “lease operators (also known as well tenders), equipment operators, maintenance and service technicians…electrical engineers…welders, pipeline layers…commercial drivers…machinists [and] warehouse operators.”

The 2019 GETI Report also notes that “the pool of available, blue-collar talent has shrunk rapidly. These skills are proving to be the most urgent of needs…In the US, blue-collar skills are more in demand than engineering roles.”

The Airswift article summarizes things succinctly:

“There is a very real problem standing on the doorstep of oil and gas companies, and it is one that needs a huge amount of effort and foresight to solve for long-term growth and success. We’re talking about the industry skills gap which is crippling energy companies, holding up work and causing projects to go over budget…More than half of professionals in the industry across the globe believe that a growing skills shortage is by [far] the biggest challenge the industry faces both now and in the future.”

Technical Training to the Rescue

As the Airswift article makes clear, oil and gas companies are learning that the skills gap is a problem that won’t go away just by throwing money at it. It requires a multifaceted approach with coordination between a variety of stakeholders, including employers, educators, workforce development programs, and even local, state, and federal governments.

Ongoing Training Is Key

Ongoing Training Is Key

While long-range plans are set into motion, employers still must do what they can in the meantime. Airswift notes that the 2019 GETI Report’s survey found that nearly two-thirds of respondents believe “companies should be turning their attention internally and retraining existing employees to deliver the skills they need to bridge the gap.”

The author of the Energy Sourcing article agrees: Training current and new employees with cross-functional skills “may be the quickest answer to the industry’s current hiring challenges.” Another strategy many employers consider is luring skilled talent away from other industries.

However, bringing in people from other disciplines isn’t a “plug and play” phenomenon. Instead, the Energy Source article points out that “when it comes to the required knowledge to be proficient in oil and gas exploration and development, they will need additional training in certain areas to enter this industry ready to be contributing members of the team.”

The oil and gas industry differs from other industries in that the wide variety of specialized skillsets it requires make initial and ongoing internal training a necessity. Two recent studies reveal the nature of this need.

The RAND Corporation study concludes:

“About half of employers (52 percent) reported employing high-priority occupations that require moderate-term on-the-job training (including inspectors, welders, and roustabouts) and about one in four employers (28 percent) reported having high-priority occupations that require long-term on-the-job training (including mechanics, machinists, and wellhead plumbers). Thus, for many of the oil and gas sector employers…it is essential to invest in and commit to providing on-the-job training to ensure their workers can adequately perform their duties.”

Similarly, SPE Research’s Training and Development Survey notes that “[u]pon starting a career [in the oil and gas industry], the majority (86.8%) of employees require training…[and] “[n]early a fifth (19.2%) required extensive training”…[and] [m]ost (82.4%) expect their employer to provide them with some of this training.”

More Than a Short-Term Solution

More Than a Short-Term Solution

The RAND Corporation study goes on to explain that training is much more than just a short-term solution:

“[A] sizeable number of high-priority occupations require long-term training…underscor[ing] the need for ongoing training and professional development after hiring to ensure that employees are getting training both for the jobs they currently have and for the jobs they might take in the future. Focusing on the workforce as a pipeline that supports careers rather than a single hiring transaction at entry is essential for sustaining the oil and natural gas industry over the long term.”

The SPE Research survey also makes a strong case for focusing on employee training as a means of not only empowering employees with the skills they need but also meeting their expectations for career development: “Overall, a wide range of skills are important for a successful career in the oil and gas industry; therefore employees place great emphasis on training and development opportunities when choosing their employers.”

The survey notes that “[i]t is important for companies to have good training and development programs, as three-quarters (74.6%) of employees state that it is important in their choice of role, and over half (53.3%) say that a lack of opportunities would be enough for them to consider leaving.”

Gaining Momentum

Gaining Momentum

It appears employers are getting the message, since “[e]ight out of ten companies provide at least some formal training as their overall approach to employee development,” and “[t]echnical training is the most common form of training provided by employers.”

This response is being echoed by other industries, including advanced manufacturing. For example, The Manufacturing Institute Training Survey recently made these key findings regarding training programs in the advanced manufacturing sector:

- “Nearly 70% of manufacturers are addressing the workforce crisis by creating and expanding internal training programs for their workforce, among other tactics.”

- “More than 79% of respondents said that they have increased their training activities.”

- “Three-quarters of respondents said that upskilling workers helped to improve employee productivity, with promotion opportunities and morale also leading the list of reasons why companies might embrace training programs.”

- “In dollar terms, the Institute estimates that the sector spent at least $26.2 billion in 2019 on internal and external training programs for new and existing manufacturing employees.”

Oil and gas companies would do well to follow the example set by manufacturers by taking on the responsibility “to build stronger pipelines to address not only the needs of their businesses but also the needs of their workers.”

Quality Matters

Quality Matters

What kind of training is necessary? The answer to that question will vary widely amongst oil and gas companies. Is your company upstream, midstream, or downstream? What roles are you having trouble filling because of the skills gap?

What will not change from company to company is the need for high-quality training that efficiently and effectively teaches current and future employees the skills they need to succeed on the job. This is particularly true for the oil and gas industry, given its broad scope of roles with specialized skill requirements.

Unfortunately, many training programs don’t meet the needs of the oil and gas industry. As the RAND Corporation study notes, “[l]ess than half of courses aimed at future workers in the oil and natural gas industry use contextualized instruction. Contextualized instruction uses occupational applications to teach basic academic skills (and vice versa) in such a way that the student learns both simultaneously.”

Teaching relevant skills in the context of the oil and gas industry is especially important because the industry is unique in so many ways. The most effective training will provide employees with hands-on experience with real oil and gas components. The RAND Corporation study supports this approach: “past research shows that contextualized instruction is an effective approach to teaching occupationally focused students…particularly when it includes ‘real-world’ simulations of workplace situations with actual workplace equipment.”

DAC Worldwide: Your Source for Effective Training Tools

DAC Worldwide: Your Source for Effective Training Tools

Oil and gas companies don’t need to recreate the wheel when looking for quality, effective technical training tools. Instead, they can rely upon a trusted training partner like DAC Worldwide to provide the guidance they need.

DAC Worldwide offers a wide variety of technical training tools specifically for the oil and gas industry. Importantly, these tools provide the contextualized, hands-on training current and future employees expect, want, and need.

Contact a DAC Worldwide representative to consult with you regarding your specific training needs. In the paragraphs that follow, we’ll take a look at just a small sample of the many training tools offered by DAC Worldwide, including training systems, cutaways, dissectibles, models, and sample boards.

Training Systems

Training Systems

Rather than broad-based training in multiple areas, DAC Worldwide’s training systems provide hands-on training focused on specific tasks. This makes them particularly helpful to employers for skill assessment (either pre-employment or for upskilling purposes).

For example, DAC Worldwide’s Vertical Separator Trainer (295-101) consists of a reduced-scale, three-phrase vertical separator that mimics its real-world counterpart by using alternate production stream components, refined oil, air, and water. It also features real industrial components, such as on-board supply pumps, a regenerative blower, a static mixer, metered valves, flowmeters, an inlet diverter, overflow weir, mist eliminator, and a custom-fabricated, large-diameter, clear acrylic, vertical separator vessel.

Cutaways

Cutaways

DAC Worldwide’s industrial component cutaways provide hands-on experience with real, industrial components that have been professionally sectioned to expose key internal components to help learners understand how they work. For industrial training relevance, common models by well-known manufacturers are chosen when manufacturing cutaways.

There are two dozen cutaways related to oil production to choose from, including a wide variety of regulators, valves, and gauges. For example, the Extended Wellhead Assembly Cutaway (295-795E) consists of a full-size, fully-detailed example of a high-pressure wellhead assembly that gives learners a first-hand view into a component found in oilfield applications worldwide. It features a variety of real industrial components learners will encounter on the job, including a casing head/starter head, tubing head, tree bonnet adapter, adjustable choke, and gate-type block valve.

Dissectibles

Dissectibles

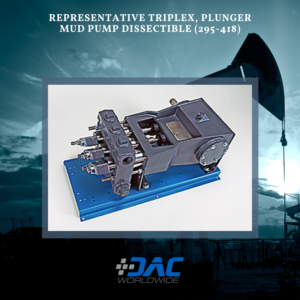

DAC Worldwide’s dissectibles take cutaways to the next level by allowing learners to disassemble and reassemble real industrial components. There’s simply no better way to train someone on the maintenance of a particular component than letting them disassemble and reassemble an actual unit. Plus, dissectibles provide experience with real components without damaging actual equipment.

For example, the Representative Triplex, Plunger Mud Pump Dissectible (295-418) is an economical, conveniently-sized triplex plunger-type mud pump assembly that teaches learners hands-on maintenance activities commonly required on larger mud pump assemblies used in upstream oilfield production operations. DAC Worldwide’s dissectible mud pump is a realistic sample that’s similar in geometry, design, and operating characteristics to the larger varieties learners will encounter on the job.

Models

Models

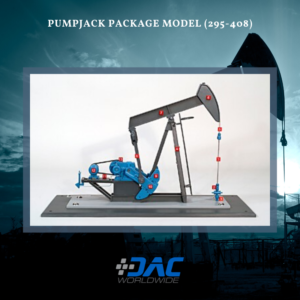

DAC Worldwide also offers a variety of incredibly-detailed, intricately-crafted models. Sometimes industrial training tends to focus so intently on the details that learners can’t see the forest for the trees. Models allow students to learn how the parts of a system work together on a small, easily-managed model without the need for a field trip to an industrial site.

There are more than a dozen models related to oil production to choose from, including separators, tanks, turbines, pumps, and piping systems. For example, the Pumpjack Package Model (295-408) is a highly-detailed, professionally-crafted technical scale model of a common oilfield production pump. Fully-detailed, this benchtop model depicts all primary pump features including counterweights, double-reduction gearbox, walking beam, horse head, sampson post, prime mover, pitman arm assembly, and representative wellhead.

Sample Boards

Sample Boards

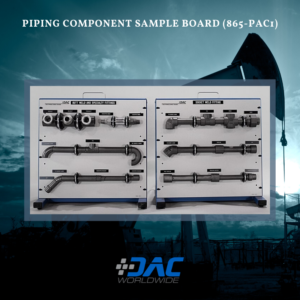

DAC Worldwide’s sample boards offer valuable maintenance training in the identification and selection of a variety of industrial components. Each sample board features a selection of real industrial components mounted with nameplates for easy association with individual components.

For example, the Piping Component Sample Board (865-PAC1) is a hands-on teaching aid designed to supplement courses in piping design, process operations, and pipe installation to help industrial maintenance technicians identify and select industrial piping components. Components from four common piping systems are provided. These samples represent a variety of piping system designs and include a broad range of fittings.

We encourage you to connect with DAC Worldwide via its social media channels, including YouTube, Instagram, LinkedIn, Twitter, and Facebook.

- Published in News