Will Geothermal Save Oil and Gas Jobs?

If someone asked you what the opposite of a fossil fuel is, what would you say? Some might say solar power, while others would point to wind. Either answer could be correct, since any form of renewable energy could be considered the opposite of our finite supply of fossil fuels like oil and gas.

Wouldn’t it be ironic then if a form of renewable energy ended up being the savior of a large chunk of oil and gas jobs? That seemingly impossible scenario is playing out right now in areas of Texas and New Mexico thanks to a resurgence of interest in geothermal energy.

In a recent article on The Hill website by Saul Elbein, the author notes that, despite the last several years representing “the height of the largest oil and gas boom in American history,” “the expansion in production has come with a sharp and protracted decline in both the number of rigs and rig workers…due to the pace of drilling and the declining need for workers amid the rise of high-tech forms of extraction.”

That’s right. Many of today’s oil and gas workers have literally drilled themselves out of a job. However, some are now learning they could be using “some of the same skills and technology used to extract fossil fuels for the production of renewable energy.”

The Permian Basin in western Texas and eastern New Mexico has recently been “the heart of the oil and gas boom.” A growing number of companies are now looking at the same area as a source of renewable energy. As Elbein points out, “beneath its bones lies another resource central to the new movement in the region’s energy industry: heat that…companies…hope to tap for clean power.”

Although “geothermal energy has long been a niche one in the renewables sector because of its reliance on a very particular set of underground conditions: accessible, superheated pools of underground water, like those found beneath pockets of California, the Pacific’s Ring of Fire and the nation of Iceland,” a growing number of companies are now “seeking to develop methods that could be used to generate geothermal power virtually anywhere in the country.”

Developing support for geothermal in the heart of oil and gas country might seem like a challenge, but investors have found proponents who see geothermal as additional security for the increasingly burdened power grid. As population, artificial intelligence (AI) data centers, and cryptocurrency mining facilities grow in number and size, geothermal sites represent the potential for “secure power sources not subject to extreme weather or alleged market manipulation by oil and gas companies.”

Perhaps more importantly for the oil and gas workforce, proponents “see geothermal as a long-term life raft for oil and gas workers increasingly idled as layoffs beset the industry.” Geothermal companies are using “oil and gas-based technologies to create the precise underground conditions needed to tap the heat beneath the region’s surface — either for electricity, industrial power or heating and cooling.”

Fortunately for oil and gas workers, geothermal has the opposite problem as traditional oil and gas, which has too many staff and rigs compared to available work. Geothermal companies have more available jobs than they have staff to support them. For oil and gas workers, the future appears to be one in which they may need a hybrid of traditional oil and gas skills mixed with geothermal expertise.

For Texas, New Mexico, and any other states navigating the transition from fossil fuels to alternative energy sources, Amatrol, along with its sister companies, DAC Worldwide and Bayport Technical, offer a wide variety of training tools and systems to teach workers the skills they need to succeed.

For example, both DAC Worldwide and Bayport Technical manufacture oil and gas training tools and systems that teach hands-on technical skills with real industrial equipment they’ll encounter on the job. Here are a couple of samples of the types of training aids these companies produce:

- DAC Worldwide’s Extended Wellhead Assembly Cutaway (295-795E) depicts the complete assembly of components used in creating a wellhead, which are used in oil & gas production operations. The full-size, fully detailed example of a high-pressure wellhead assembly gives learners a first-hand view into a component that is found in oilfield applications worldwide.

- Bayport Technical’s Cooling Tower Working Demonstrator (142-CT2) is a scaled, acrylic replica of a forced draft cooling tower used in oil refineries and petrochemical plants. This working demonstrator allows a full view of how water is filtered through the tower to cool it off and then return it the factory. This tabletop system includes a water basin and distribution system, heater assembly, pump, fan, splash bars, air intake louvers, draft eliminators, and temperature gauges.

When it comes to teaching the geothermal skills workers will need, Amatrol’s geothermal training system combines in-depth curriculum with real industrial equipment:

- Amatrol’s 950-GEO2D Geothermal Troubleshooting Learning System with Desuperheater uses an exposed component layout so that learners can see each component’s role in a geothermal system. Learners can easily observe, monitor, and test each component mounted and labeled on a vertical panel. Sight glasses installed in the 950-GEO2D allow the learner to see the refrigerant’s changing state as it passes through the system. Amatrol also includes pressure and temperature gauges at key points to show the system’s performance at a glance. Additionally, the system includes a custom designed, temperature-controlled ground simulator so the system can run continuously.

Reach out to an expert training consultant with Amatrol today to get started on the path to training the next generation of workers!

- Published in News

Biomanufacturing Plays Larger Role in Chemical Production

Have you noticed how technology continues to change nearly every aspect of our lives? Or are you so used to it by now that new technological developments don’t even register anymore?

One area where you might take notice of new technology is at work. When you must adapt to new processes related to new technologies, it’s hard to ignore. Manufacturers everywhere adopt new technologies for a variety of reasons.

Often, new technologies bridge the gap left by having too few skilled workers to fill open positions. At other times, manufacturers seek a boost in productivity and efficiency that automating processes can provide.

Increasingly, though, research and development of new manufacturing technologies comes as a result of the pursuit of sustainability. The importance of fossil fuels and related products in manufacturing cannot be overstated. However, these products and their negative impact on the environment have led many manufacturers to search for alternatives that are sustainable and less harmful.

In a Chemistry World article, author Sarah Houlton discusses the companies exploring the use of biotech processes to manufacture chemicals. She gives several examples of manufacturers who “use bio-based raw materials, captured CO2 and recycled plastics as raw materials for new chemicals.”

For example, Houlton points out that German manufacturer Covestro makes “aniline from biomass via a fermentation process.” Doing so could “offer a more sustainable alternative to traditional petrochemical processing, and be more amenable to biobased raw materials.”

Not all biomanufacturing is new, though. Houlton notes that “BASF…has been working on industrial biotechnology for more than three decades, first for the animal feed enzyme phytase, and then shifting vitamin B2 production from a chemical to a biotech process more than 20 years ago.”

Biotech processes in chemical manufacturing are particularly attractive because “[t]aking a biotechnology approach also allows a much wider range of starting materials to be tapped into.” For example, Houlton notes that many “products are made by fungal or microbial fermentation processes, with renewable raw materials like sugars and vegetable oil that are rarely suitable for traditional chemical processes.”

Indeed, biomanufacturing represents “a promising alternative to petrochemical-based manufacturing,” because “using fermentation to produce chemicals is reducing the reliance on non-renewable fossil fuels.”

In addition, “[f]ermentation also presents a safe, lower energy consumption alternative. Unlike many chemical manufacturing processes that require high heat or pressure, fermentation typically operates at lower temperatures and pressures. Biomanufacturing also allows for the manufacture of complex biomolecules such as proteins, which are not readily made by chemical synthesis processes.”

While these new technologies present exciting alternatives for the future, those involved in hiring workers for the chemical manufacturing industry probably wonder where the workers for these advanced facilities will come from.

As always, the need for workers with advanced process control and instrumentation skills remains great. Proactive manufacturers will look to establish a pipeline of fresh talent from local schools while also seeking to upskill current workers.

Fortunately, manufacturers don’t have to reinvent the wheel when it comes to effective process control and instrumentation training. Partnering with a training solutions provider with a proven track record can help any manufacturer or educational institution train workers with the hands-on skills they’ll need to hit the ground running in the workplace.

For example, DAC Worldwide offers a wide variety of training systems that teach basic to advanced process control and instrumentation skills. Its newest flagship process control and instrumentation trainer, the Smart Process Plant Training System (603-SP), is a fully-functional, industrial-quality fluid process system that provides hands-on training in the measurement and control of five of the most common process variables: level, pressure, temperature, flow, and pH.

The system groups these process control elements into one complete piping system, which allows it to teach multiple configurations of flow loops, controls, and communications. The system incorporates both new and legacy technologies so that users are prepared for anything they might encounter on the job.

The Smart Process Plant Training System features a wide variety of common, industrial-quality components and instruments to provide learners with a realistic training experience that will build skills that translate easily to the workplace. The Smart Process Plant also includes multiple experiments, which simulate both continuous and batch process control loops that are widely used in many process industries. The Smart Process Plant Training System is only one of DAC Worldwide’s many process control and instrumentation training systems. Visit DAC Worldwide online to learn more about its many other training systems, as well as advanced chemical engineering training systems from its partner, Pignat SAS!

- Published in News

New Consortium Seeks to Advance Pharmaceutical Manufacturing

If the nation’s manufacturers ever hope to bridge the ongoing skills gap that prevents them from filling the hundreds of thousands of open manufacturing positions across the country, they’re going to have to get creative in terms of building partnerships with the educators preparing the next generation of workers.

Who else is better positioned to advise today’s educators about the skills workers need than the very companies that will be hiring students upon graduation? Yet, too few companies reach out to the educators in their area to build relationships with them and their students. Fortunately, some educational institutions are taking the lead in building the very important partnerships that will allow manufacturers to thrive for years to come.

For example, in a recent Contract Pharma article, author Kristin Brooks reports that “Purdue University, in collaboration with Eli Lilly and Co. and Merck & Co. Inc., launched the Young Institute Pharmaceutical Manufacturing Consortium, a collaborative effort to pioneer advances in pharmaceutical manufacturing.”

Brooks notes that “[o]perating within Purdue’s William D. and Sherry L. Young Institute for Advanced Manufacturing of Pharmaceuticals, consortium partners aim to revolutionize pharmaceutical manufacturing with a focus on sterile injectables and innovative aseptic manufacturing technology to ensure quality, safety and compliance.”

Karen Plaut, Purdue’s executive vice president for research, explains: “We’re on the frontier of Pharma 4.0 — autonomous experimentation, advanced robotics, big data, smart factories, AI and machine learning. Through this partnership, we will have a global impact in solving complex problems in the pharmaceutical and biopharmaceutical manufacturing ecosystem.”

Brooks points out that “[t]he consortium will rely on the research strengths of Purdue, Lilly and Merck, leveraging the organizations’ collaborative research relationship and workforce development programs…together with industrially relevant education and training for the next generation of scientific leaders and researchers.”

When it comes to training the next generation of advanced manufacturing workers, educators and industry partners alike would do well to partner with experts in technical training, such as DAC Worldwide. For example, consortium members could benefit from DAC Worldwide’s Smart Process Plant Training System (603-SP), a fully-functional, industrial-quality fluid process system that provides hands-on training in the measurement and control of five of the most common process variables: level, pressure, temperature, flow, and pH.

The system groups these process control elements into one complete piping system, which allows it to teach multiple configurations of flow loops, controls, and communications. The system incorporates both new and legacy technologies so that users are prepared for anything they might encounter on the job. These technologies work together to form a 3-level communication architecture:

- Device Level: Smart sensors monitor Level, Flow, Temperature, Pressure, and pH. They are connected via either IO-Link and Ethernet communication or HART communication.

- Control Level: A DCS and various PLCs and PIDs allow for operation and control of the system’s components.

- Enterprise Level: The DCS software provides Supervisory Control with data analytics for monitoring smart production, smart maintenance, etc.

The Smart Process Plant uses a Distributed Control System (DCS) that features Supervisory Control software. This software is Rockwell Automation’s PlantPAx, and it acts as the backbone of the system. It gathers and organizes data and creates dashboards that represent the real-time status of the processes being carried out by the system.

The Smart Process Plant Training System features a wide variety of common, industrial-quality components and instruments to provide learners with a realistic training experience that will build skills that translate easily to the workplace. The Smart Process Plant also includes multiple experiments, which simulate both continuous and batch process control loops that are widely used in many process industries. These experiments include:

- Basic and Advanced Bioreactor Applications

- Clean-In-Place (CIP) Skid Application

- Boiler Drum Level Application

- Wastewater Treatment Application

With these experiments, learners will explore a wide variety of fundamental process control topics, including: temperature, level, flow, pressure, and pH ratio control; agitation; sequence control; continuous control; 3-element control; feed forward/cascade control; and pump lead/lag demand. The Smart Process Plant Training System is only one of DAC Worldwide’s many process control and instrumentation training systems. Visit DAC Worldwide online to learn more about its many other training systems, as well as advanced chemical engineering training systems from its partner, Pignat SAS!

- Published in News

Room for Improvement in Workplace Safety

“Safety first!” If you work in the manufacturing sector, you’ve probably seen and heard that phrase a million times. And there’s nothing wrong with that. No one wants to work in a facility that puts them at risk of serious injury or even death.

Unfortunately, too many workers do suffer workplace injuries every year. The number and severity of these injuries remain a constant reminder that there’s always room for improvement when it comes to workplace safety.

In a recent EHS Today article, author Adrienne Selko notes that “US businesses need to ‘do significantly better’ in supporting workplace safety, according to a recent survey from BSI.” BSI’s Xavier Alcaraz notes that “[w]e’ve normalized a culture where…’safety first’ is promoted but supervisors look the other way when deadlines are at risk.”

Things don’t have to stay that way, however. Workers deserve better. BSI offers some practical advice for manufacturers seeking to improve workplace safety:

- “Safety culture: Foster an environment where safety is a systems-driven core value, encouraging reporting of potential hazards and near-misses without fear of reprisal. This contributes to both physical safety as well as psychological safety.”

- “Adopt a management systems approach for health and safety that emphasizes continuous improvement.”

- “Align safety goals with business goals.”

- “Safety training: Provide comprehensive safety training, including proper use of equipment, emergency procedures, and hazard recognition.”

That last suggestion is an important one that too many companies ignore. Of course, not all companies prioritize safety like they should, but even those wanting to improve don’t always know how to go about adequately training workers.

For companies looking to improve their safety training, partnering with established companies to provide industrial-quality training systems that will stand the test of time will help ensure the continued safety of the workforce.

For example, DAC Worldwide offers two safety training systems specifically designed to give employees the hands-on experience they need to master lock-out/tag-out skills:

- DAC Worldwide Lock-Out/Tag-Out Training System

- DAC Worldwide Electrical Lock-Out/Tag-Out Training System

Be sure to check out these training systems and contact a DAC Worldwide representative to learn how you can improve your training today!

- Published in News

Turning Trash into Treasure

If the future has a color, it’s surely green. From alternative energy to renewable resources to green technology, the idea that we must reduce, reuse, and recycle is far from a new one. However, it’s not always about abandoning the way we’ve always done things. Sometimes it’s a matter of combining the old with the new.

According to a recent Interesting Engineering article by Mrigakshi Dixit, “Phoenix Tailings, a company founded by MIT alumni…is developing a method to recover rare earth metals and nickel from mining waste.”

The Woburn, Massachusetts, company discovered that “[r]are earth elements, essential for the magnets in wind turbines and electric vehicles…are often locked away in mining waste.” While China currently leads the world in production of these high-demand elements, Phoenix Tailings believes it can become a significant source of these elements in the near future.

“Their innovative process uses water and recyclable solvents to extract rare earth metals from mining waste. The metals are then purified using a unique electrochemical process that’s both efficient and environmentally friendly.”

The company’s process “eliminates toxic byproducts and reduces carbon emissions, making it a sustainable solution for the future.” The company believes it can “produce over 3,000 tons of these critical metals by 2026.”

Phoenix Tailings expects to supply “customers with several rare earth elements, including neodymium and dysprosium, which are crucial components in magnet production.” With the help of “over $2 million from the U.S. Department of Energy,” the company’s materials will benefit a variety of industries, including “wind energy, electric vehicles, and defense technology.”

Fortunately, the company’s “process can handle various ore types and mining waste. Moreover, the company has access to abundant resources as the U.S. mining industry generates approximately 1.8 billion tons of waste each year.”

As Phoneix Tailings expands and other companies mimic their processes, there is great potential for growth in turning mining waste into valuable rare earth elements needed for the technologies driving the future. What these companies will need more of is a supply of skilled workers to fill open positions as expansion takes place. That’s why DAC Worldwide offers a variety of hands-on training tools designed to teach the industrial skills workers need in the modern workplace. For example, be sure to check out DAC Worldwide’s Process Control and Instrumentation training tools and contact a DAC Worldwide representative to learn how you can improve your training today!

- Published in News

Fiber-Reinforced Plastic Replacing Stainless Steel in Industrial Strainers

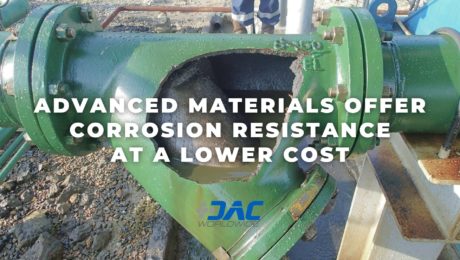

Industrial strainers play a critical role in a wide variety of process control applications. According to a recent New Equipment Digest article by Del Williams, “from desalination, wastewater treatment, and irrigation to power generation and the production of food, pharmaceuticals, consumer, and industrial products,” “[i]ndustrial strainers are essential for screening out debris and large particulates to protect crucial downstream equipment and processes.”

For many applications, strainers constructed of standard carbon steel are perfectly fine. However, experts note that “corrosive environments such as those involving seawater, erosive slurries, or aggressive chemicals can quickly corrode conventional equipment. This can lead to potential issues in safety, quality, and compliance as well as production downtime, requiring premature strainer component replacement.”

For these harsh environments, “duplex or super duplex stainless-steel construction is used to resist corrosion, but at considerable cost.” That’s why many industries have been searching for “a more economic, durable alternative,” and they may have found it in fiber-reinforced plastic (FRP).

Robert Presser, Vice President of Acme Engineering Prod., Inc., a North American manufacturer of industrial self-cleaning strainers, claims that “[t]oday, a much more cost-effective option is to use Fiber-Reinforced Plastic (FRP) strainers that are specifically designed to be resistant to corrosive environments at a fraction of the cost of duplex or super duplex stainless steels.”

So what exactly is FRP? According to Williams, “FRP is a composite material made up of polymer and supported with fibers for added strength. FRP is already widely used for applications such as the power plant piping used to carry seawater for once-through process cooling.”

Williams notes that “[w]ithin industrial markets, OEMs are now using FRP in various applications where superior corrosion resistance is required at lower cost…Industries can save approximately half the cost or more when the strainer’s intake vessels and piping are built with FRP, and only the internals are constructed with super duplex.”

Regardless of what materials they’re made of, industrial strainers remain an important piece of many different types of process applications. Maintenance technicians must be familiar with different types of strainers, including how to keep them operating at peak efficiency.

That’s why DAC Worldwide offers several training tools designed to help industrial maintenance technicians become familiar with industrial strainers:

- DAC Worldwide’s Dual Basket Straining System Cutaway (273-330) is a realistic sectioned example of a duplex basket strainer commonly found in petro-chemical plants, refineries, and other similar industrial environments. Often used in process applications where significant debris is encountered, these easily-maintained devices dependably protect downstream equipment, such as centrifugal pumps, meters, valves, and spray nozzles from damage.

- DAC Worldwide’s Single Basket Straining System Cutaway (273-320) is a realistic sectioned example of a simplex basket strainer.

- DAC Worldwide’s Y-Type Straining System Cutaway (273-310) is a realistic, sectioned example of a y-type strainer. It supports training relating to industrial, commercial, and domestic process systems. Y-type strainers mechanically remove solids from flowing liquids and gases by incorporating a removable wire mesh or perforated straining element. Capable of withstanding significant pressures, the device is commonly used to protect heat exchangers, pumps, valves, and other valuable process equipment.

Be sure to check out DAC Worldwide’s other Process Control and Instrumentation training tools and contact a DAC Worldwide representative to learn how you can improve your training today!

- Published in News

Indiana Building a Biopharmaceutical Manufacturing Talent Pipeline

What comes to mind when you think about Indiana? Fields of corn? The Indy 500? If educational institutions and industry partners have their way, you might soon be adding another thing to that list: biopharmaceutical manufacturing.

According to a recent Inside INdiana Business article, author Alex Brown notes that the federal Economic Development Administration has designated Indiana consortium Heartland BioWorks as “a regional technology and innovation hub.”

As such, Heartland BioWorks “has established BioTrain, a training institute designed to prepare talent for entry-level biomanufacturing roles.” The overall goal is to “help build a talent pipeline in biopharmaceutical manufacturing.”

How important is it to increase the number of skilled workers in biomanufacturing? According to Vince Wong, CEO of Indianapolis-based BioCrossroads, the sector needs “about 2,400 to 3,700 employees in biopharma manufacturing every year for the next 10 years.”

To meet such a huge demand for biomanufacturing workers, companies and educational institutions must work together “to develop an infrastructure of training to make sure that we have have a robust workforce to meet that.”

That’s why BioTrain “aims to address the specific skills and qualifications needed to tackle workforce shortages in the life sciences.” In Indiana, what that looks like is a partnership with “BioCrossroads, Purdue University, and Ivy Tech Community College,” among others.

The BioTrain facility “will feature a combination of classroom and hands-on training on state-of-the art equipment that will allow participants to earn stackable credentials that will help them earn entry-level biomanufacturing roles that can feed into existing higher credentials for technician, engineer, or scientist positions.”

The facility will be able to train “college students, industry workers looking to upskill, as well as those coming from other industries.” Users will have access to some of the best training equipment and curriculum available, such as DAC Worldwide’s Smart Process Plant Training System (603-SP), a fully-functional, industrial-quality fluid process system that provides hands-on training in the measurement and control of five of the most common process variables: level, pressure, temperature, flow, and pH.

The system groups these process control elements into one complete piping system, which allows it to teach multiple configurations of flow loops, controls, and communications. The system incorporates both new and legacy technologies so that users are prepared for anything they might encounter on the job. These technologies work together to form a 3-level communication architecture:

- Device Level: Smart sensors monitor Level, Flow, Temperature, Pressure, and pH. They are connected via either IO-Link and Ethernet communication or HART communication.

- Control Level: A DCS and various PLCs and PIDs allow for operation and control of the system’s components.

- Enterprise Level: The DCS software provides Supervisory Control with data analytics for monitoring smart production, smart maintenance, etc.

The Smart Process Plant uses a Distributed Control System (DCS) that features Supervisory Control software. This software is Rockwell Automation’s PlantPAx, and it acts as the backbone of the system. It gathers and organizes data and creates dashboards that represent the real-time status of the processes being carried out by the system.

The Smart Process Plant Training System features a wide variety of common, industrial-quality components and instruments to provide learners with a realistic training experience that will build skills that translate easily to the workplace. The Smart Process Plant also includes multiple experiments, which simulate both continuous and batch process control loops that are widely used in many process industries. These experiments include:

- Basic and Advanced Bioreactor Applications

- Clean-In-Place (CIP) Skid Application

- Boiler Drum Level Application

- Wastewater Treatment Application

With these experiments, learners will explore a wide variety of fundamental process control topics, including: temperature, level, flow, pressure, and pH ratio control; agitation; sequence control; continuous control; 3-element control; feed forward/cascade control; and pump lead/lag demand. The Smart Process Plant Training System is only one of DAC Worldwide’s many process control and instrumentation training systems. Visit DAC Worldwide online to learn more about its many other training systems!

- Published in News

Biotech has the Potential to Revitalize U.S. Manufacturing

The history of manufacturing in the United States covers more than a century and contains more ups and downs than the most thrilling roller coaster in any theme park. For many years, particularly those decades after the end of World War II, the U.S. led the world in manufacturing output and innovation.

Beginning in the 1980s, however, historians note a steady decline in American manufacturing as the U.S. moved toward a service-based economy and other countries around the world began to offer cheaper production options. The last few years since the COVID-19 pandemic have seen a resurgence of manufacturing in the U.S.

Will it continue? Experts believe that it can indeed continue, and one of the areas that could spur the most new jobs might surprise some: biotech. In a recent IndustryWeek article, author Douglas Friedman sets forth his belief that “we have a unique opportunity to leverage exciting advancements in biotech to bring back and diversify wide swaths of manufacturing production.”

Friedman explains that “[b]ioindustrial manufacturing uses biological systems—including microbes such as bacteria, yeast, and algae—to produce new materials or sustainable alternatives that are incorporated into products we use every day, like bio-based cement, plant-based nylon, and lab-grown cocoa.”

According to Friedman, by continuing “the development of innovative biotechnologies that improve our health, food and environment…the U.S. can become the world leader in bioindustrial manufacturing, creating millions of jobs in the process.”

In fact, the U.S. is already seeing benefits from bioindustrial manufacturing. Friedman points out that bioindustrial manufacturing already accounts “for roughly $440 billion added to our bioeconomy as of 2019 and 1.65 million jobs created by the bioproduct industry as of 2017.” As this sector grows, Friedman estimates that “[e]ach additional 1% of the market share brought to the U.S. through bioindustrial manufacturing would add $60 billion to the U.S. economy.”

While biotech holds great potential for expanding U.S. manufacturing, hurdles remain, including a significant one facing all manufacturers: finding skills workers to fill open positions. Workers in bioindustrial manufacturing facilities will need hands-on skills working with advanced automation technologies, as well as process control and instrumentation equipment.

Fortunately, employers don’t have to reinvent the wheel when it comes to effective process control and instrumentation training. Partnering with a training solutions provider with a proven track record can help any manufacturer or educational institution train workers with the hands-on skills they’ll need to hit the ground running in the workplace.

For example, DAC Worldwide offers a wide variety of training systems that teach basic to advanced process control and instrumentation skills. Its newest flagship process control and instrumentation trainer, the Smart Process Plant Training System (603-SP), is a fully-functional, industrial-quality fluid process system that provides hands-on training in the measurement and control of five of the most common process variables: level, pressure, temperature, flow, and pH.

The system groups these process control elements into one complete piping system, which allows it to teach multiple configurations of flow loops, controls, and communications. The system incorporates both new and legacy technologies so that users are prepared for anything they might encounter on the job.

The Smart Process Plant Training System features a wide variety of common, industrial-quality components and instruments to provide learners with a realistic training experience that will build skills that translate easily to the workplace. The Smart Process Plant also includes multiple experiments, which simulate both continuous and batch process control loops that are widely used in many process industries. These experiments include:

- Basic and Advanced Bioreactor Applications

- Clean-In-Place (CIP) Skid Application

- Boiler Drum Level Application

- Wastewater Treatment Application

The Smart Process Plant Training System is only one of DAC Worldwide’s many process control and instrumentation training systems. Visit DAC Worldwide online to learn more about its many other training systems!

- Published in News

Electrical Lock-Out/Tag-Out Skills Essential to Industrial Workplace Safety

Workplace safety remains the bedrock upon which all industrial skillsets are built and for good reason. Modern industries require workers with a wide variety of skills, from basics like electrical, hydraulics, and pneumatics, to more advanced skills involving operating, maintaining, troubleshooting, and repairing advanced automation technologies.

No matter how highly skilled a worker might be, however, nothing will matter if the fundamental basics of safety aren’t mastered. When it comes to safety, one of the most important skills that workers must learn is how to work safely with electricity.

According to a FacilitiesNet article by Ashley Beebe, “[w]hen working with electrical distribution systems and components, frontline maintenance technicians and engineers often face the potential for serious injury or death from electrocution or arc flashes, but knowledge of safety tips, procedures, codes and regulations can help technicians and engineers lessen the risk and potential for serious injury or death.”

That’s why, “[a]ccording to the Occupational Safety and Health Administration (OSHA), employees must not work near an electric current, any equipment, or a part they may come in contact with while on the job, unless it has been de-energized. If an electric current has not been de-energized, employees must be protected by isolation, insulation, warning signs or other methods.”

According to OSHA, “[e]nergy sources…in machines and equipment can be hazardous to workers. During the servicing and maintenance of machines and equipment, the unexpected startup or release of stored energy can result in serious injury or death to workers.”

That’s why the control of hazardous energy, often known by its more popular moniker “lock-out/tag-out or LOTO,” is such an essential part of basic safety training. Teaching workers hands-on LOTO skills will help them to understand how to properly control hazardous energy and maintain a safe work environment.

For companies looking to improve their safety training, partnering with established companies to provide industrial-quality training systems that will stand the test of time will help ensure the continued safety of the workforce.

For example, DAC Worldwide offers a safety training system specifically designed to give employees the hands-on experience they need to master electrical lock-out/tag-out skills. DAC Worldwide’s Electrical Lock-Out/Tag-Out Training System (810-000) features an affordable, portable tabletop trainer with hands-on activities related to the process of identifying and locking out sources of dangerous electrical energy in an industrial setting.

All lock-out/tag-out skills are performed at reduced voltage (24VDC) for the enhanced safety of users. Moreover, test points allow users to verify components are deenergized after lock-out/tag-out. Indicator lights also provide visual confirmation that circuits are deenergized.

Users will gain hands-on experience with real-world industrial components, such as a clamp-on circuit breaker lock-out 480/600V; clamp-on circuit breaker lock-out 120/277V; wall switch lock-out; knife-type disconnect switch; IEC rotary safety switch; 3-in-1 plug lock-out; and a universal multipole breaker lock-out. A toolbox with locking and tagging devices is also included. Be sure to check out DAC Worldwide’s Electrical Lock-Out/Tag-Out Training System online and contact a DAC Worldwide representative to learn how you can improve your training today!

- Published in News

DAC Worldwide’s Smart Process Plant Offers Unparalleled Process Control Training

Many different types of manufacturing processes depend upon the carefully-controlled movement of fluids, such as liquids and gases, through a complex system. That’s why process control and instrumentation are vital parts of many major industries, including: power generation; petrochemicals; food processing and bottling; chemical manufacturing; biotechnology; pharmaceuticals; refineries; and more.

For example, a recent IndustryWeek article by Gerry Abbey and Lance Heinen details the “journey to embrace smart manufacturing technology” made by “Texas’s largest pickle manufacturer,” Best Maid Pickles. “Founded in 1926, Best Maid Pickles” sought to improve productivity and efficiency as the organization continued to expand its operations.

The authors note that, “[a]cross the food and beverage industry, the adoption of smart manufacturing technologies, while extremely desirable, has been slowed by concerns around cost, lack of knowledge and lack of skills.” However, with proper research and strategic implementation, these technologies can transform a business.

Best Maid Pickles stands as a perfect example of such transformation. As the authors conclude, “the Best Maid Pickles journey illustrates how embracing smart manufacturing technology can drive efficiency, productivity and profitability…The implementation delivered a significant ROI through reduced costs and increased revenue, empowering Best Maid for sustained growth and success.”

The authors believe that, “[b]y leveraging technology, companies can position themselves for a thriving future in the ever-evolving manufacturing landscape.” The journey will not be without its challenges, however, and those must be anticipated and tackled head-on.

One common challenge when implementing new advanced automation technologies is the need for highly skilled workers to operate, maintain, troubleshoot, and repair these new systems. Whether a company decides to search for new employees with the skills they need or train current employees to equip them with necessary skills, employers must focus on ensuring workers possess the hands-on process control and instrumentation skills they require.

Fortunately, employers don’t have to reinvent the wheel when it comes to effective process control and instrumentation training. Partnering with a training solutions provider with a proven track record can help any manufacturer or educational institution train workers with the hands-on skills they’ll need to hit the ground running in the workplace.

For example, DAC Worldwide offers a wide variety of training systems that teach basic to advanced process control and instrumentation skills. Its newest flagship process control and instrumentation trainer, the Smart Process Plant Training System (603-SP), is a fully-functional, industrial-quality fluid process system that provides hands-on training in the measurement and control of five of the most common process variables: level, pressure, temperature, flow, and pH.

The system groups these process control elements into one complete piping system, which allows it to teach multiple configurations of flow loops, controls, and communications. The system incorporates both new and legacy technologies so that users are prepared for anything they might encounter on the job. These technologies work together to form a 3-level communication architecture:

- Device Level: Smart sensors monitor Level, Flow, Temperature, Pressure, and pH. They are connected via either IO-Link and Ethernet communication or HART communication.

- Control Level: A DCS and various PLCs and PIDs allow for operation and control of the system’s components.

- Enterprise Level: The DCS software provides Supervisory Control with data analytics for monitoring smart production, smart maintenance, etc.

The Smart Process Plant uses a Distributed Control System (DCS) that features Supervisory Control software. This software is Rockwell Automation’s PlantPAx, and it acts as the backbone of the system. It gathers and organizes data and creates dashboards that represent the real-time status of the processes being carried out by the system.

The Smart Process Plant Training System features a wide variety of common, industrial-quality components and instruments to provide learners with a realistic training experience that will build skills that translate easily to the workplace. The Smart Process Plant also includes multiple experiments, which simulate both continuous and batch process control loops that are widely used in many process industries. These experiments include:

- Basic and Advanced Bioreactor Applications

- Clean-In-Place (CIP) Skid Application

- Boiler Drum Level Application

- Wastewater Treatment Application

With these experiments, learners will explore a wide variety of fundamental process control topics, including: temperature, level, flow, pressure, and pH ratio control; agitation; sequence control; continuous control; 3-element control; feed forward/cascade control; and pump lead/lag demand. The Smart Process Plant Training System is only one of DAC Worldwide’s many process control and instrumentation training systems. Visit DAC Worldwide online to learn more about its many other training systems!

- Published in News

DAC Worldwide Offers Hands-On Electrical Generation Fundamentals Training

Industrial facilities know how important electrical skills are to ensuring that things run smoothly and safely. What many people don’t know, however, is how diverse electrical skills can be. While basic electrical skills, such as wiring a circuit or troubleshooting a transformer, are extremely valuable and quite common, some facilities require specialized advanced electrical skills, such as those relating to power generation and managing multiple power plants on an electrical grid.

For example, one industry that’s currently booming will likely lead to a need for workers with advanced electrical skills related to power generation. Which industry are we talking about? Semiconductor manufacturing!

According to a recent article in The Register, author Tobias Mann notes that “AMD president Victor Peng addressed [at the recent Hot Chips Conference] one of the biggest challenges facing the semiconductor industry as it grapples with growing demand for ever larger AI models: power.”

How big is the challenge facing the semiconductor manufacturing industry? Mann points out that “AI’s seemingly insatiable thirst for power has gained considerable attention over the past year – so much so that some operators have begun setting up shop next to nuclear power plants. And the problem isn’t going to get easier.”

According to Mann, Peng has expressed worry about “finding enough power sources and being concerned about the grids and the distribution.” In fact, Mann notes that Peng has “noted that these [AI] models have very quickly gone from requiring hundreds of megawatt hours to train to hundreds of gigawatt hours.”

How do you address such a large-scale challenge? “Peng argues that the semiconductor industry needs to focus more attention on making the infrastructure not only more performant, but more efficient.” Indeed, the burgeoning semiconductor manufacturing industry must bring together all the players necessary to craft large-scale infrastructure solutions that ensure that the electrical grids of tomorrow will be able to support the demands of new technologies.

Addressing fundamental electrical generation challenges will require highly skilled workers who possess advanced electrical skills related to power generation. Hands-on training in electrical generation fundamentals can elevate workers’ skills to the next level.

For example, DAC Worldwide’s Electrical Generation Fundamentals Training System (490-000) represents a true simulator depicting multiple power plants on a grid. The unit basically acts as the control center for a generating station and simulates four separate generating units. The system demonstrates the principles of generator operation and represents the relationships that an operator must master in order to confidently operate generators.

Practice in paralleling machines of various sizes is easily accomplished without tying up the plant simulator. The synchroscope display includes a phase angle display, representing the phase difference between running and incoming.

A graphic representation of how load is shared, by two machines of various sizes, is shown by a house curve. The relationship between real load and reactive load is displayed by meters and by a pictorial diagram of the power triangle on the graphic display. Inductive, resistive, and capacitive loads can be turned on and off reinforcing the effects of reactive load and demonstrating how power factor can be changed.

Users will study topics, such as AC generators, reactive power control, loss of load, and trainer operation. They will also practice hands-on skills, such as correctly performing paralleling operation, generator responses to inductive/resistive/capacitive loads, calculating power factor, and observing a diesel generator autostart and load. The Electrical Generation Fundamentals Training System is only one of DAC Worldwide’s many electrical training systems. Visit DAC Worldwide online to learn more about its many other electrical training systems!

- Published in News

Data-Driven Maintenance Leads to Continuous Improvement

What’s the most-feared word in the manufacturing sector? While there certainly are a wide variety of candidates, we’d be willing to bet that “downtime” is quite high on the list. No manufacturer likes to hear that critical machinery is down, leading to production delays and potentially expensive repair costs.

When looking for ways to boost productivity and efficiency, many manufacturers analyze downtime statistics to try to figure out what’s causing downtime and how to minimize it. Is a particular machine to blame? Are machines not being maintained in a timely manner? Is equipment not being utilized appropriately?

Unfortunately, too many manufacturers have nothing to analyze other than miscellaneous reports by maintenance managers. That’s why rubber compounding manufacturer Hexpol Compounding America (HCA) recently invested in a computerized maintenance management system (CMMS).

According to a recent IndustryWeek article by Dennis Scimeca, maintenance at HCA was “not a focus at the executive level.” However, after implementation of a CMMS, leadership realized that the CMMS could “lay the groundwork for a new, company-wide total preventative maintenance (TPM) initiative” that “ties directly into…HCA’s corporate strategy plan[, which] includes continuous improvement and lean management goals.”

For example, the CMMS allowed HCA to take “a data-rich approach to boost equipment availability and found continuous improvement opportunities throughout all of its operations.” One focus was on inventory reduction, keeping track of “parts inventories and repairs to determine how shelf-life relates to replacement-part needs.”

The CMMS provided some interesting insights: “O-rings don’t last forever. If you sit on a part for 10 years, if it has rubber seals in it, it’s probably bad. We probably shouldn’t be holding on to that because it’s a cost. If we’re relying on that part to work in 10 years and it fails right away, it did us no good to even hold that part.”

Likewise, “[i]f they sit too long, the bearings in large motors flatten because of the weight. Something as simple as rotating a shaft a quarter turn once a month prevents those motors from becoming write-offs and incurring replacement costs. The CMMS determines the best PM schedules to avoid the motors from failing.”

HCA’s maintenance leaders have been pleased with how the CMMS has helped them use real data to drive changes. According to HCA’s CEO, “We’re only doing the things that we know we can control and that are actually going to give us the benefits we need.” And how do they know it’s working? “[T]he CMMS provides real truth on whether the new policies deliver results or not.”

The data provided by the CMMS has also helped HCA leaders to work more closely together. Quarterly one-on-one meetings with site leaders “make sure larger goals meet the specific needs of individual plants and that everyone has the resources they need…A good example is trying to find maintenance technicians. If we have three openings at a site and not seeming like we’re getting any resumes for interviews I can try to go to HR and figure out what’s going on. What do we need to do to get this done?”

Speaking of maintenance technicians, it’s no surprise that HCA’s multiple locations would still need to hire highly skilled maintenance technicians. The CMMS didn’t reduce the need for ongoing reactive and proactive maintenance. To the contrary, it provided data to support the importance of maintaining equipment on a regular basis to optimize efficiency and productivity.

For companies like HCA, that means hiring new maintenance technicians with the skills they need to succeed, as well as upskilling current maintenance workers to ensure they’re up to the task of tackling the maintenance priorities the CMMS highlights. For many companies, this will mean making investments in things like ongoing training, in addition to new technology, like a CMMS.

For companies looking to set up or improve their maintenance training, a thorough review of current training materials is a great place to start. Do employees have access to hands-on training with actual components they’ll encounter on the job? If not, partnering with established companies to provide industrial-quality training systems that will stand the test of time will help ensure the productivity of the workforce.

For example, DAC Worldwide offers a wide variety of training systems specifically designed to give employees the hands-on experience they need to master essential industrial maintenance skills. Be sure to check out DAC Worldwide’s advanced manufacturing training systems and contact a DAC Worldwide representative to learn how you can improve your training today!

- Published in News