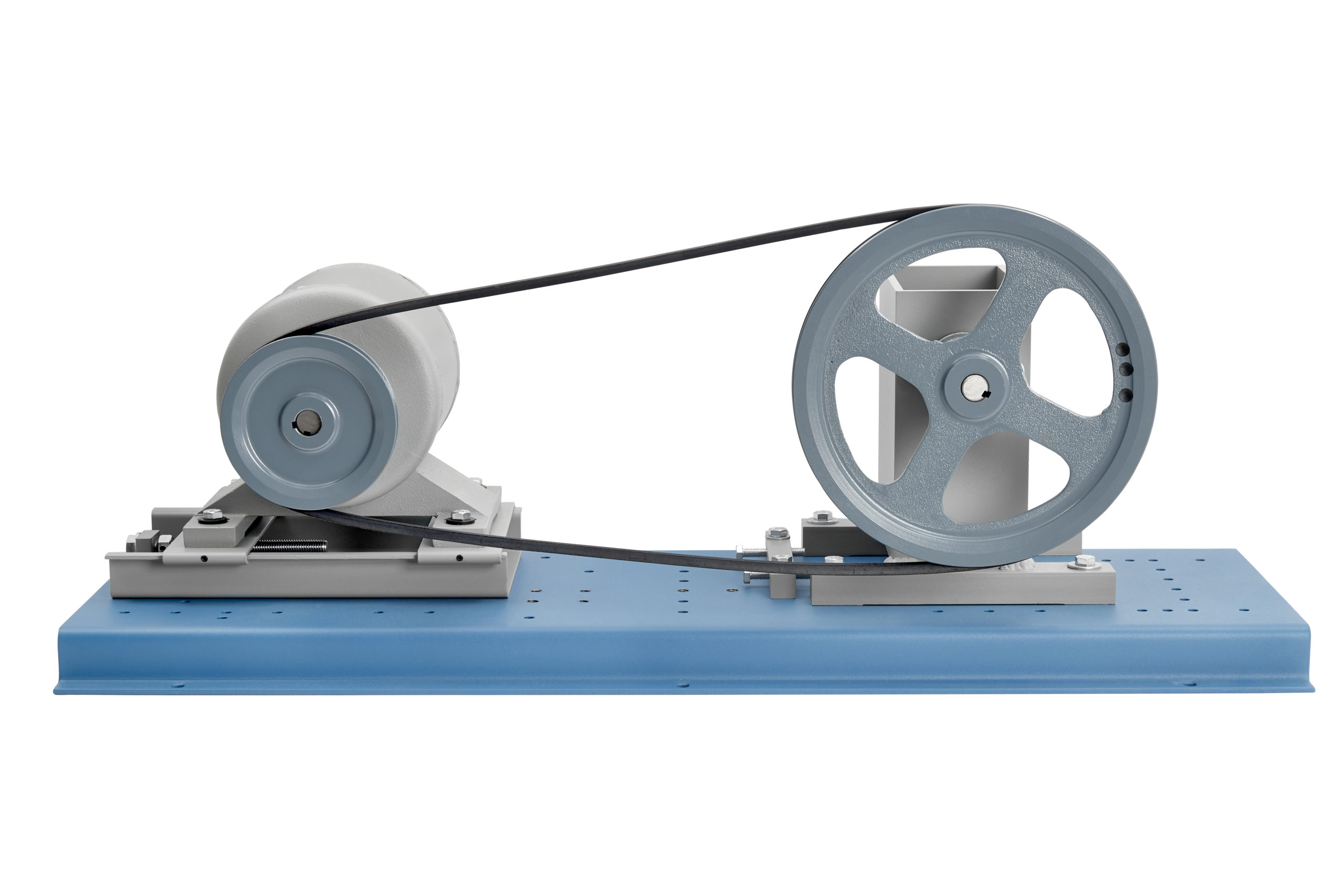

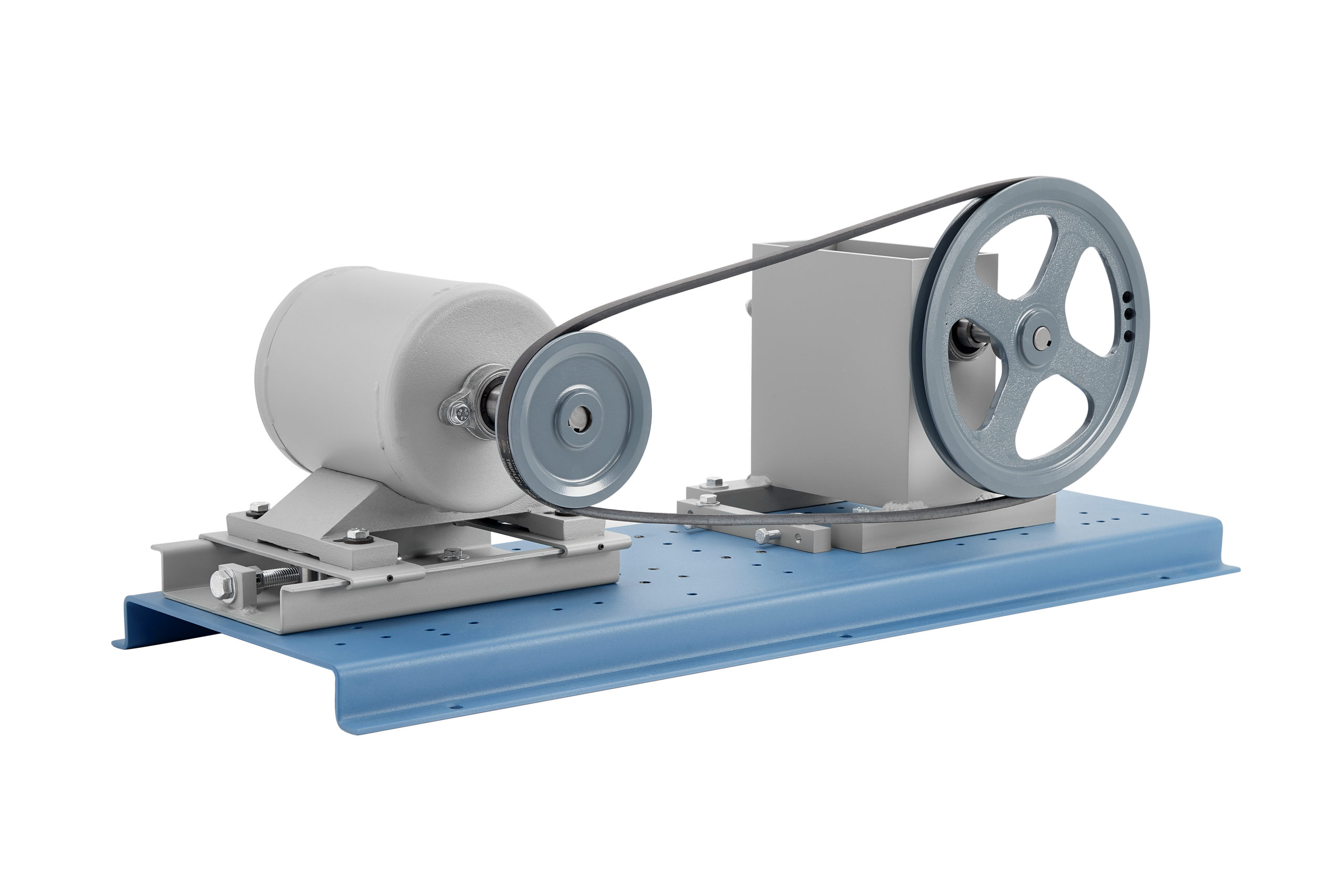

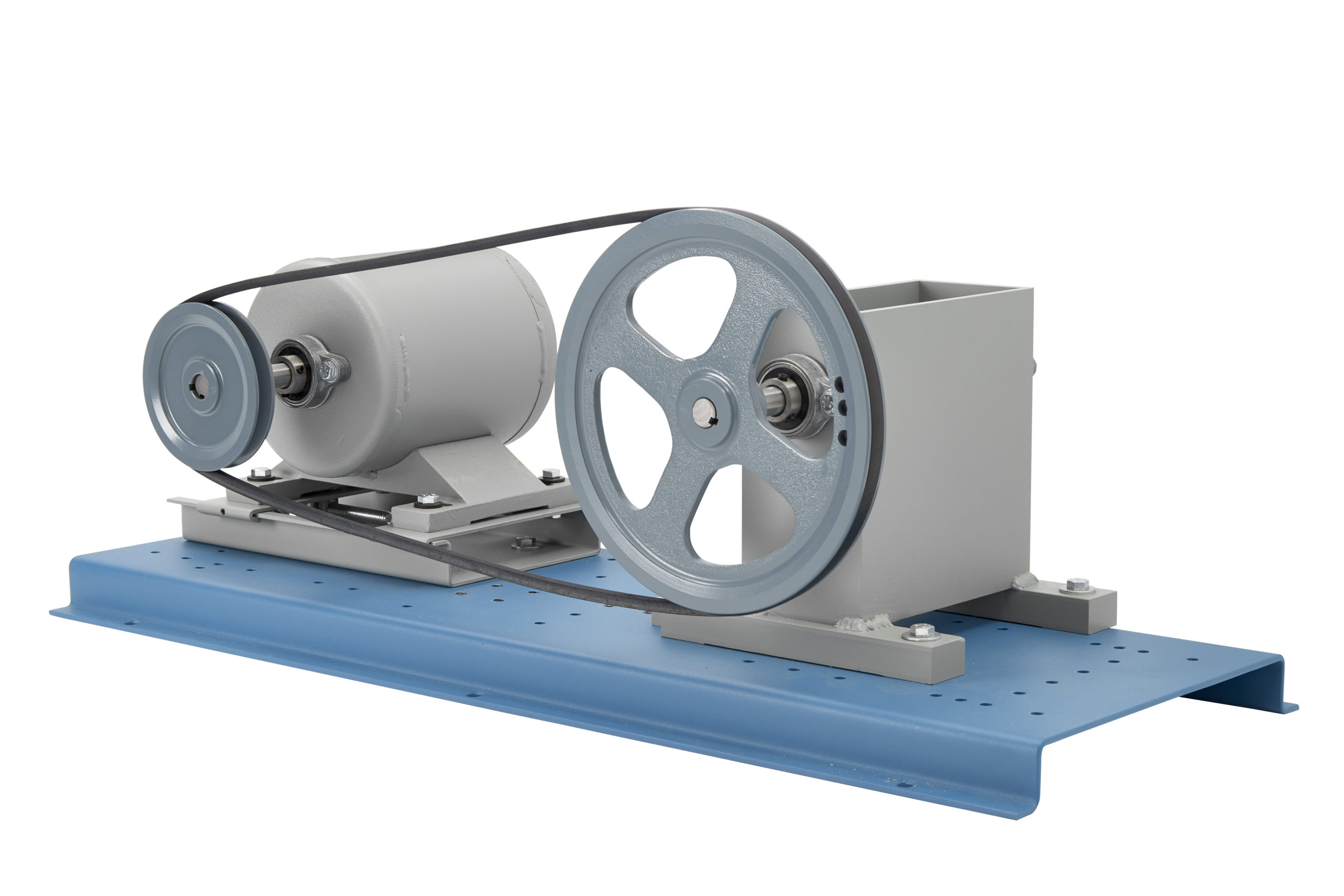

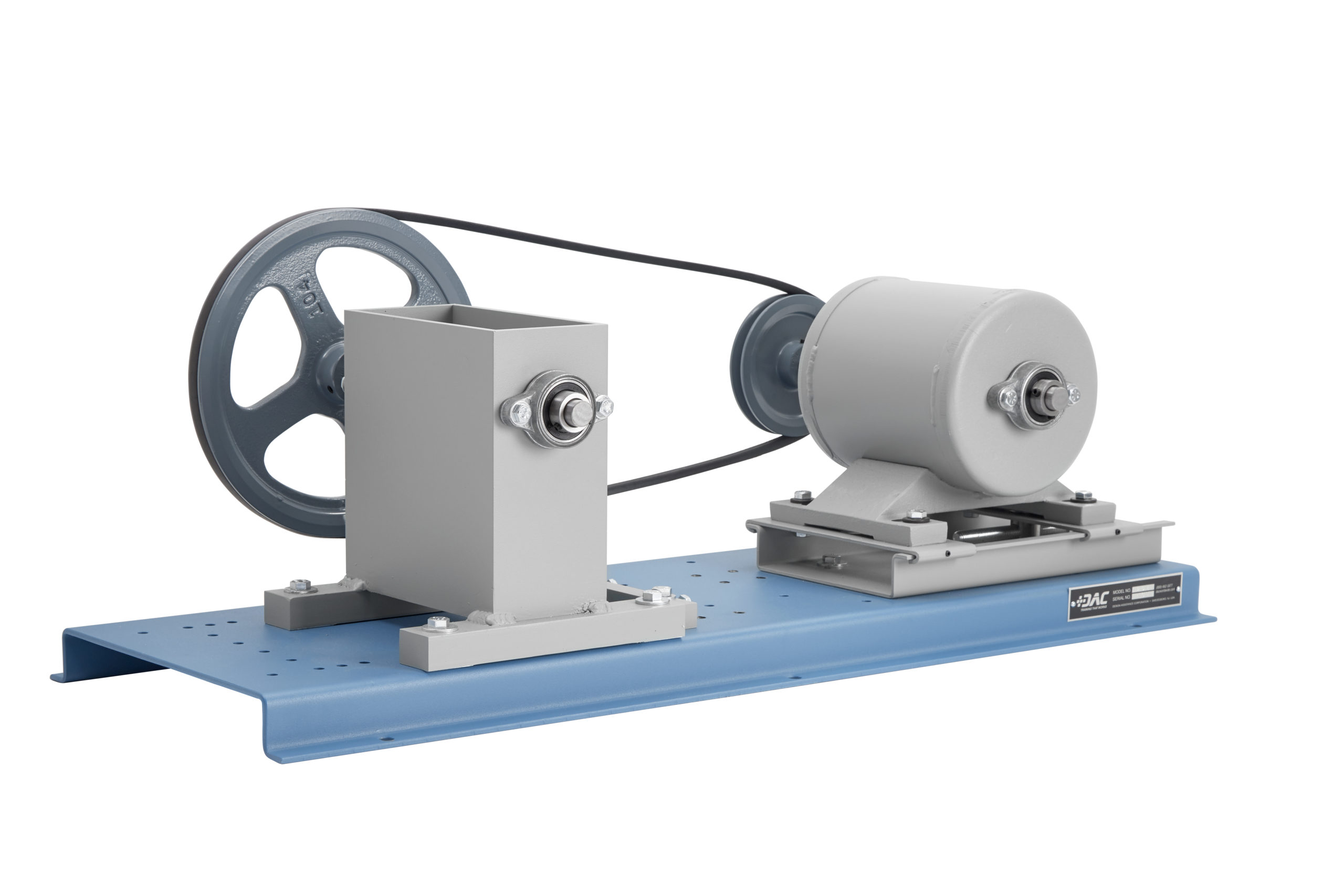

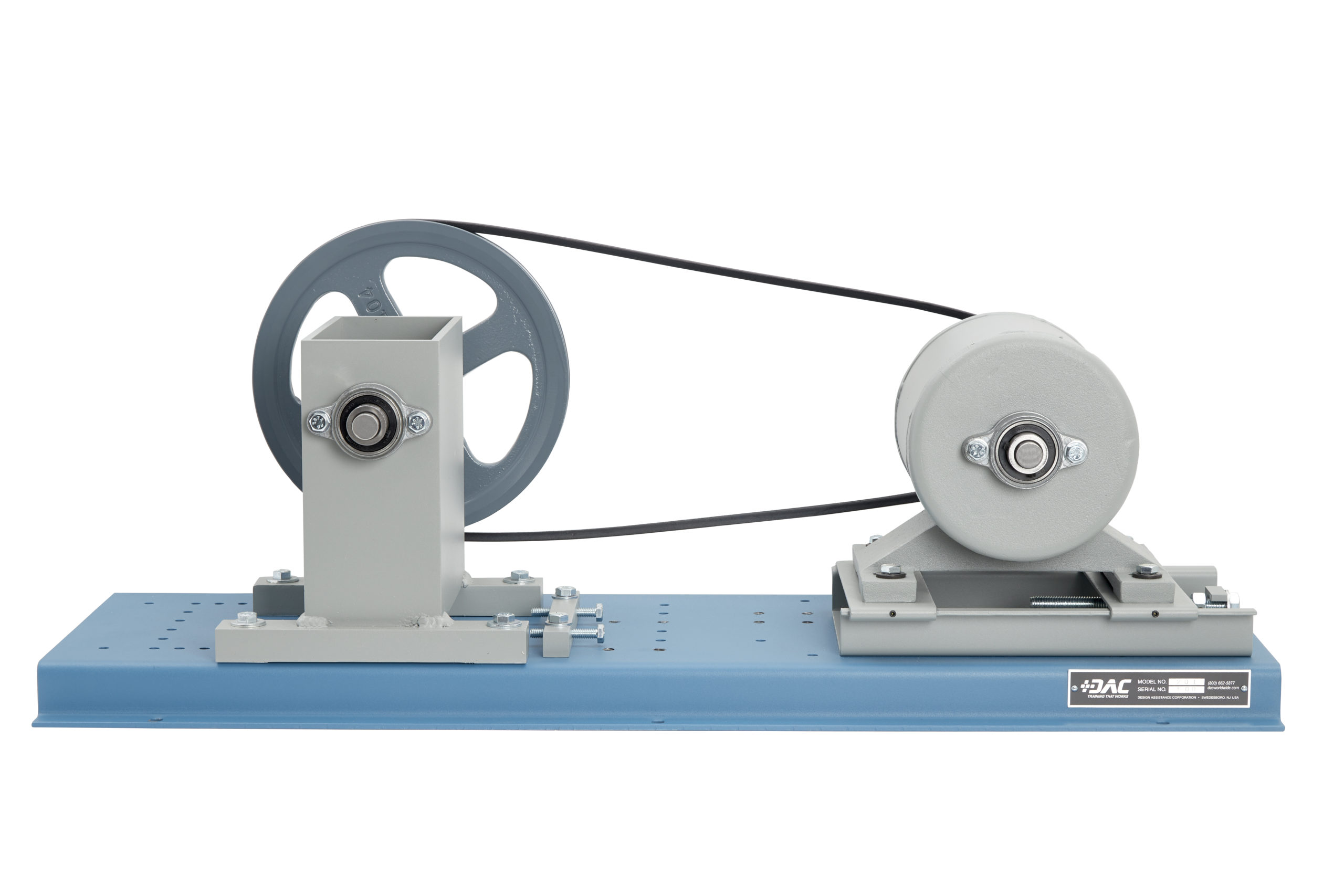

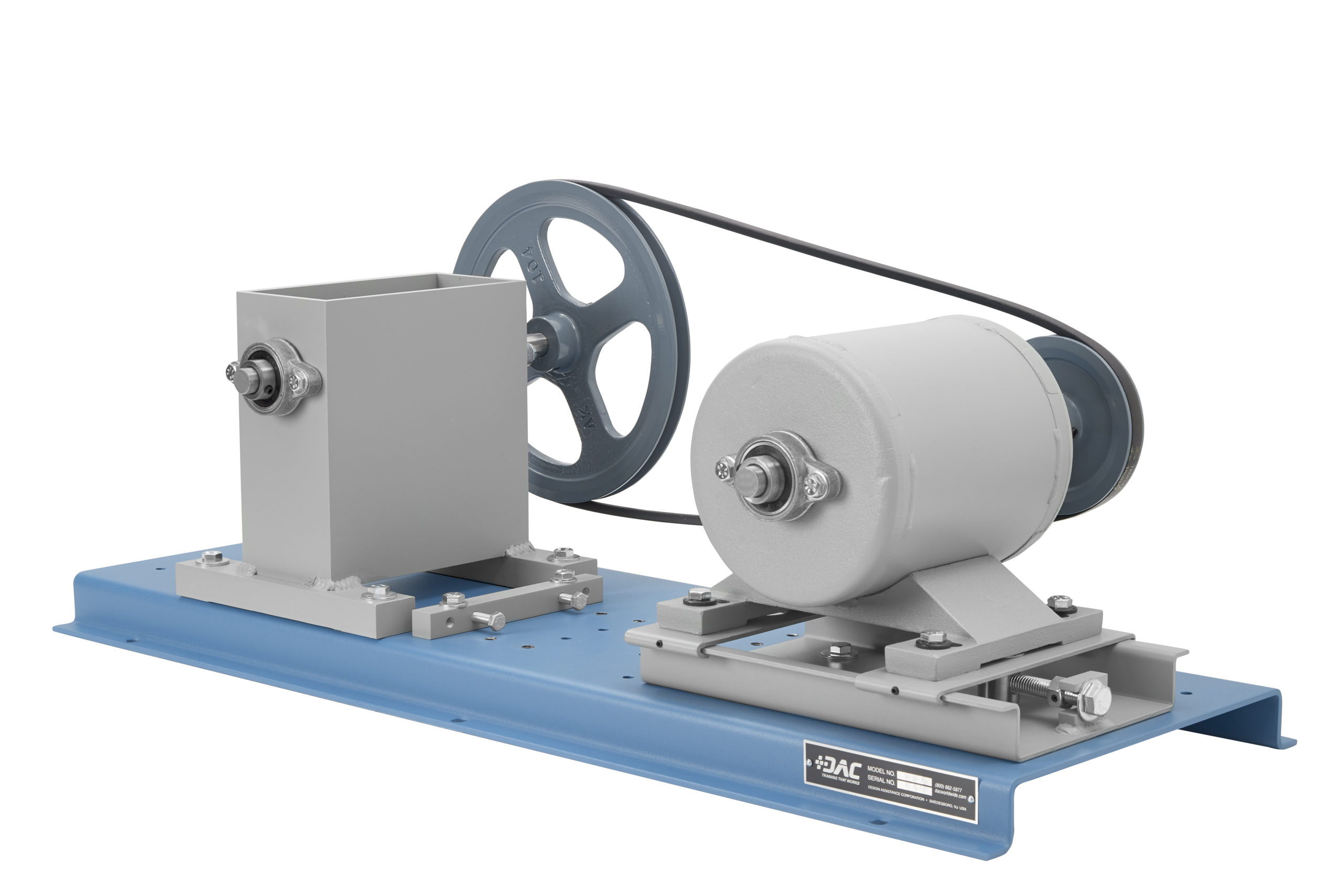

- 7-gauge, formed-steel baseplate with provision for tabletop mounting.

- Welded aluminum motor and driven elements.

- High-durability powder coating, allowing for repeated use and rough handling.

- Multiple motor positions allow for demonstration of multiple tensioning requirements.

- Heavy-duty, adjustable motor base for parallel tensioning.

- Provision for two-point tensioning using jacking bolts.

- Heavy-duty, flanged bearings allowing for variations in shaft misalignment.

- Fractional horsepower belts and sheaves, allowing for installation at two shaft centerline distances.

- Multiple Type-A belt sets, including tapered bushing, 2-groove sheaves, matched belts, and a mismatched belt example.

- Positive drive belt set including belt and sheaves.

- Sheave bushings, including QD and taper-lock varieties.

- Belt maintenance tool set.

- Provision for mounting on related bench and workstation products.

- Belt sample set (nine samples).

- Belt tension gauge.

- Sheave inspection gauge.

- Allen wrench set.

- Combination wrenches.

- Straight edge/rule.

- String.

- Angle indicator.

- Shim selection (five each of five sizes).

- Toolbox.

- Use/Exercise Guide with 12 hands-on exercises.

- Industrial Trades Training Manual with 55-page section on belt drives (IPT).

- Gates Belt Preventive Maintenance Manual.

- Packaging for shipment via motor freight.

DISCLAIMER: Product Dimensions are approximate. Shipping Dimensions and Weights are for directional use only and may change based on manufacturer variables. For the most accurate Shipping Dimensions and Weights, please contact the manufacturer.

- Product Dimensions

(L x W x H)

36in. x 13in. x 14in. (910 x 330 x 350 mm)

70lbs. (32kg) - Shipping Dimensions

(L x W x H)

40in. x 15in. x 24in. (1020 x 380 x 610 mm)

136lbs. (62kg)

- Required #208-015 - Magnetic Base/Dial Indicator Set

- Recommended #902F - Electromechanical Workstation

- #099-00S - DVD, Power Transmission Installation and Maintenance Training (IBT)

- #201-002 - Wedge Belt and Sheave Set

- #201-005 - Sheave/Sprocket Laser Alignment Tool

- #208-003 - Standard Shim Kit

- #510-000 - Industrial Trades Manual (IPT)

- #510-001 - Industrial Trades Handbook (IPT)

- #837-PAC - Belt Sample Board

- #201-001 - Chain Drive

- #201-006 - High Torque, Synchronous Belt Drive Set (Poly Chain)

- #201-500 - Use/Exercise Guide, Belt Drive Training System

- #201-PAC - Belt Drive Training System Plus