Piston pumps are positive displacement pumps that move and pressurize fluid by using the force of a reciprocating piston moving in an enclosed cylinder. The piston draws fluid into the cylinder and pushes it out under pressure as the volume in the cylinder gets progressively larger and then smaller as the piston reciprocates.

Sometimes referred to as plunger pumps, piston pumps can be powered in a variety of ways, including electric motors, internal-combustion engines, or even by hand, wind, or flowing water. Since they can generate high pressures, piston pumps can move viscous fluids that contain solid particles.

These versatile pumps have a wide variety of commercial and industrial applications, such as: hydraulic pumps to power heavy machinery; commercial car washes; water irrigation or delivery systems; pressure cleaning equipment; small machines like paint sprayers; reverse osmosis systems; oil production; chemical processing; and multiple other uses within the aerospace, marine, agriculture, and automobile industries.

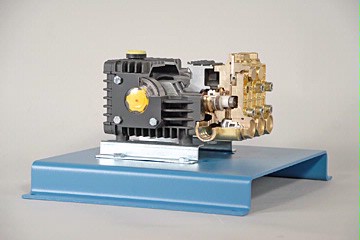

DAC Worldwide’s Piston Pump Cutaway (278-132) is a sample industrial piston pump that has been carefully sectioned and color-coded to train learners in the design, operation, construction, and maintenance of this common process pump used throughout industry.

The cutaway exposes and showcases the complete internal configuration of an industrial piston pump. Moreover, seal features, bearings, and hardware locations have been retained to allow realistic, hands-on pump maintenance and operation training.

Industry-Standard Components Provide Realistic, Hands-On Training

Technical training is most effective when learners can gain hands-on practice with industry-standard components they’ll encounter on the job. The Piston Pump Cutaway features a common, industrial-quality piston pump sourced from common pump makes and models, such as General, Giant, Kerr, and Cat Pump, to provide learners with a realistic training experience that will build skills that translate easily to the workplace.

The Piston Pump Cutaway is a sturdy unit whose primary features have been retained, and replacement hardware is supplied where necessary. To make identification easier, component parts, such as gaskets, seals, and bearings, are clearly visible.

The cutaway is cleaned, primed, and painted using a high-durability polyurethane coating. It comes on a formed-steel, powder-coated baseplate but can also be mounted on a compatible DAC Worldwide workstation.

Expand Training Capabilities with Custom Options

The Piston Pump Cutaway can be customized with available options to match a particular industry’s or user’s specific needs. In industry, one size rarely fits all and this trainer can be tailor-made to your exact needs.

For example, the Piston Pump Cutaway can be mounted on DAC Worldwide’s Electromechanical Workstation (902). In addition, a Metering Pump Handbook is available to expand training options.