- Welded aluminum base assembly using 1.5" square, 1/8" wall tubing

- 16-Gauge formed-steel support structure, allowing for attachment to base assembly or associated mounting bench products

- 16-Gauge, formed-steel electrical enclosure

- Powder-coated surfaces throughout

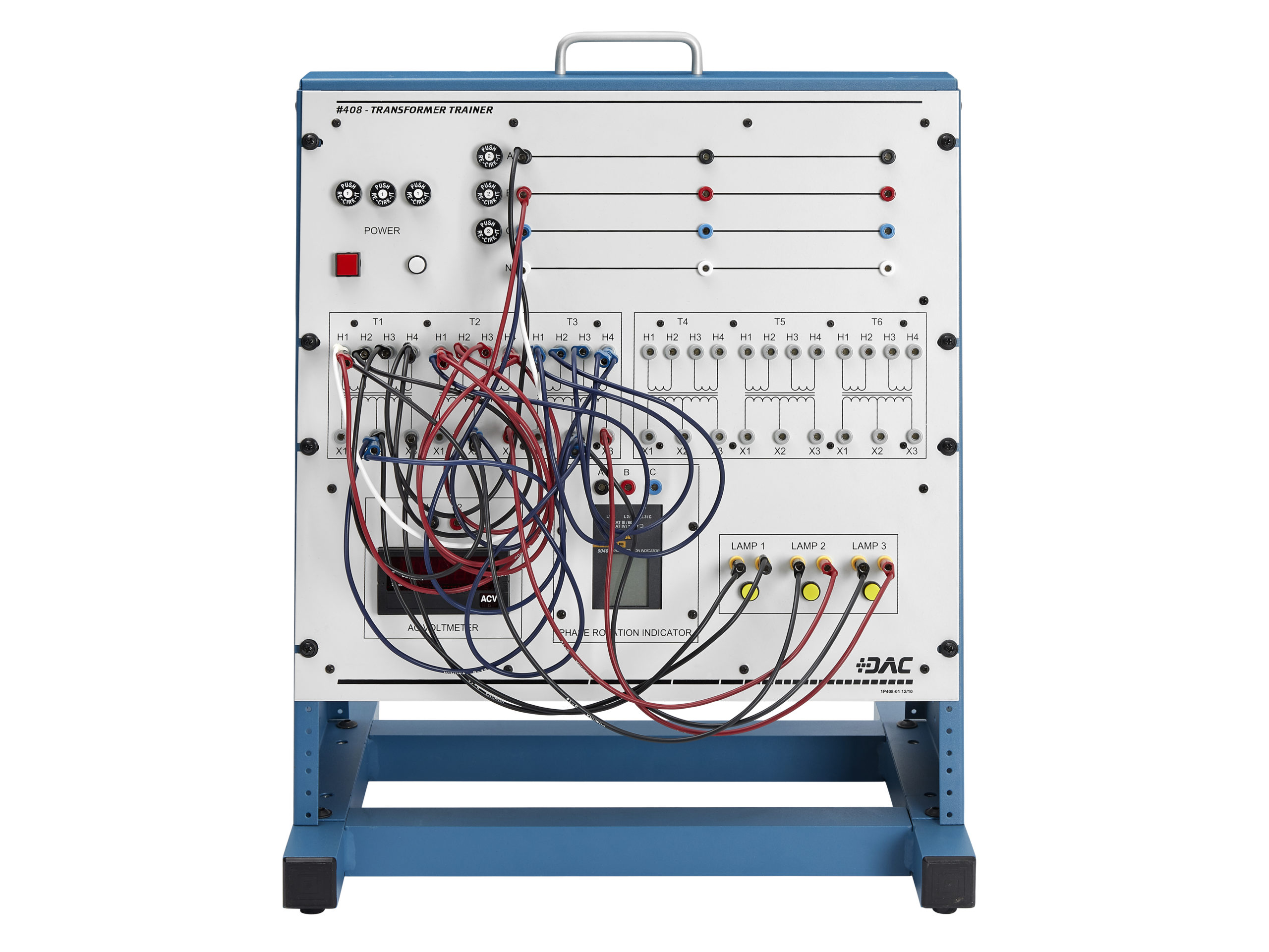

- Powder-coated and silk-screened 1/8" aluminum front panel face, 19" x 18.5"

- Keyed instructor power switch

- Circuit breaker with provision for lock-out/tag-out

- Pilot light and emergency stop switch

- Internal electrical interlock, de-energizing power when opening electrical enclosure

- Color-coded banana-jack receptacles for all transformers and associated components

- Permanent internal grounding (not dependent on student wiring)

- Eight (8) instructor fault switches (rear of device)

- Allows for both single-phase and three-phase activities

- Banana jack connections used throughout

- Low-voltage operation using step-down transformers

- Internally-fused

- Packaging for shipment via motor freight

DISCLAIMER: Product Dimensions are approximate. Shipping Dimensions and Weights are for directional use only and may change based on manufacturer variables. For the most accurate Shipping Dimensions and Weights, please contact the manufacturer.

- Product Dimensions

(W x H x D)

19in. x 19in. x 15in. (480 x 480 x 381 mm)

45 lbs. (23 kg) - Shipping Dimensions

70 lbs. (28 kg)

- 208V/60Hz/3Ph power

- Patch cords

- Panel-mounted voltmeter and phase rotation meter

- Use/Exercise Guide

- #560-000 - Electrical Trades Training Manual (IPT)

- #560-001 - Electrical Trades Handbook (IPT)

- #902 - Electromechanical Workstation

The courseware, useful in both an instructor-led or self-directed format, includes illustrated, hands-on exercises, including:

- Perform single-phase transformer connections

- Analyze transformer single phase voltages

- Identify three-phase connections

- Interconnect multiple transformers in Wye or Delta configurations

- Analyze three-phase voltage readings

- Identify “transformer turns ratio” (TTR)

- Demonstrate how three-phase transformer connections can produce incorrect motor rotation

- Demonstrate how to parallel single-phase and three-phase transformers

- Simulate a burned-out transformer in a three-phase bank