DAC Worldwide is a world leader in technical training solutions for industrial skills including a full range of training/assessment systems, industrial cutaways, & custom scale models.

T (800) 662 5877

Email: sales@dacworldwide.com

DAC Worldwide

601 Heron Drive, Swedesboro, NJ USA 08085

Chemical Engineering | Advanced Laboratory Training

Solutions

Continuous Distillation - DVI/100

Pignat's compact, benchtop Continuous Distillation trainer (DVI/100) allows students to operate a continuous distillation process. Expertly crafted glass components show the flow of fluid through the complete process in both liquid and gaseous phases. With an efficient startup time, steady-state operation can be reached in 20 minutes.

A digital touch screen HMI controls operating parameters (flowrates, reflux ratio, heating, etc.) and displays real-time measurements across the process. Data is saved for later analysis. The trainer can also be used for the study of mass and thermal balance, yield, hydrodynamics of a column, flooding conditions, packing factor, and more. Educational handbook and technical manual included.

- Thermosiphon boiler

- Bubble trays column

- External reflux

- Feeding pump, with bypass valve

- Distillate pump

- Column bottom pump

- Glass preheating, two coils

- Glass boiler, 1.3 L, heater

- Low level detector

- Glass column bubble cap plates

- Glass condenser, glass coil

- Cooler, in glass, glass coil

- Distillate receiver

- Bottoms receiver

- 4 temperature probes Pt100Ω

- Differential pressure

- Flowmeters

- Level sensor with vibrating blades

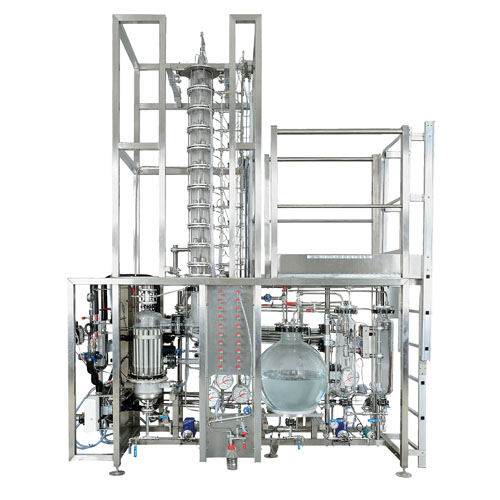

Batch Continuous Distillation - DVI/3000

Pignat's standard-size, floor-standing Batch Continuous Distillation trainer (DVI/3000) allows students to operate both a continuous and batch distillation process. Expertly-crafted glass components (column, boiler, condenser, etc.) show the flow of fluid through the complete process in both liquid and gaseous phases. Multiple interchangeable column options are available (bubble cap tray, packing, etc.)

With an efficient startup time, steady-state operation can be reached in 20 minutes. A digital touch screen HMI controls operating parameters (flowrates, reflux ratio, heating, etc.) and displays real time measurements across the process. Data is saved for later analysis. The trainer also supports the study of mass and thermal balance, yield, hydrodynamics of a column, flooding conditions, packing factor, and more. Educational handbook and technical manual included.

- Operate a batch distillation process

- Venting thermostat

- Pressure relief on preheater

- Metering pump

- Electrical pre-heater

- 3 feeding levels on the column

- 6L glass shell heater equipped with a resistance overflow tube

- Glass column with Multiknit packing and SS sampling flange

- Glass reflux head, with reflux dividing solenoid valve

- SS & glass coil condenser

- 2 graduated glass receivers, 1L

- Temperature probes Pt100Ω

- 1 differential pressure transmitter

- 1 flowmeter

- 1 level sensor

- 1 touch screen with data acquisition

Controlled Distillation Unit - OTP-DC

Pignat's Controlled Distillation Unit (OTP-DC) is an automated, controlled, continuous distillation pilot plant. This industrial-scale unit allows students to study unit operations, maintenance, and process supervision. Expertly-crafted glass components show fluids as they flow through the process. The column (6-in. diameter) can be fed at several feed points along the stainless steel plates placed across the column.

Flow transmitters, temperature sensors, and pressure indicators allow the user to monitor the process and study the influence of the process parameters and operating conditions. The DCS and software application developed for this unit allows parameter variations, process automation, and data acquisition in real time or historical. The trainer also supports the study of transitional phases, equilibrium conditions, multivariable process implementation, and more. The unit is also customizable to fit your specific process needs.

- OTP pilot allows learners to understand the continuous distillation process and work on an industrial scale in various fields, including chemical engineering, maintenance, and supervision

- 1 glass tank 100 L

- 3 gear pumps

- Thermosiphon re-boiler made of a glass shell and a SS tube heat exchanger fed by steam

- 2 product glass vessels

- A SS pre-heat exchanger

- Column with SS bubble cap trays

- Condenser, glass shell and SS tube

- Distillate circuit

- Pneumatic pump and centrifugal pump for feeding and transfer

- Scale and SS welded frame

- 17 temperature probes Pt100Ω

- Vortex flow transmitter

- 5 flow transmitter

- Differential pressure transmitter

- 2 manometers

- 2 rate control

- 3 level transmitter

Benchtop Gas-Liquid Absorption - ABS/100

Pignat's Gas Liquid Absorption trainer (ABS/100) is a compact, benchtop unit that allows students to operate a packed gas absorption column. The absorption process, used in gas scrubbing, involves transferring material from a gaseous mixture (solute) into a liquid (solvent). This process is very common in industry for treating polluted discharge gases.

The two phases (liquid and gas) become intimately mixed as they pass through the column packing, allowing components from the solute to migrate from the gas phase to the liquid phase. The solute-enriched liquid phase is drawn off at the base of the column, while the depleted gaseous phase leaves from the head of the column.

The trainer allows students to study the absorption of NH3 or CO2 in water, determine the material balance of the gaseous solute, influence of operational parameters on efficiency of the column, thermal balance, packing factor, and more. Educational handbook and technical manual included.

- Mass transfer between gas-phase and liquid-phase

- Tabletop unit

- Liquid-phase feeding pump, magnetic drive, sampling valve

- Glass column, in three parts: (1) column head, with SS plate equipped with a liquid flow diffuser; (2) packed section, glass Raschig rings 6×6, SS packing support; and (3) column bottom, SS plate

- Enriched liquid-phase magnetic pump

- Receiver, polyethylene, draining valve

- Graduated glass funnel, 2.5L

- 2 pipe U manometers

- 2 water flowmeters

- CO2 flowmeter

- Air flowmeter

Gas-Liquid Absorption - ABS/2000

Pignat's Gas-Liquid Absorption trainer (ABS/2000) is a standard-size, floor-standing unit that allows students to operate a packed gas absorption column. The trainer features industry-standard components, such as an in-line gas analyzer, column sampling, U-tube manometers, etc.

The trainer allows students to study the absorption of NH3 or CO2 in water, determine the material balance of the gaseous solute, influence of operational parameters on efficiency of the column, thermal balance, packing factor, and more. Educational handbook and technical manual included.

- Mass transfer between gas phase and liquid phase into a packed column

- Unit delivered with educational handbook and technical documentation

- Column

- Glass Raschig rings packing (6×6 mm)

- 20L polyethylene tanks

- Metering pump, settable flowrate

- Damping system

- Graduated glass receiver

- Digital thermometers

- Air flowmeter

- Water flowmeter

- Gas flowmeter CO2

Controlled Absorption & Regeneration Unit - ABR/3000

Pignat's state-of-the-art, hands-on Controlled Absorption & Regeneration Unit (ABR/3000) allows students to study the gas-liquid absorption process and the regeneration solvent process all-in-one. The solute migration process from the gas to liquid phase occurs when both phases are in contact in the packing of the reverse flow absorption column. This highlights the absorption operation (solvent purification).

The regeneration process is observed on the second column, which is continuously fed. An energy‐saving heat exchanger is placed between the two columns to optimize energy usage. With this unit, students are able to study various control loops, determine mass balance, and process efficiency. The unit also includes a LabView monitoring system.

- CO2 capture technology implementation

- Unit delivered with educational handbook and technical documentation

- Possibility to customize the unit

- Commissioning & training on site

- Absorption column, glass Raschig rings packing

- Liquid distributor

- 2 gear pumps

- SS exchanger, energy recovery

- SS preheating exchanger

- SS cooling exchanger

- Regeneration column, glass Raschig rings packing

- 6L glass boiler with inside SS coil

- Condenser, glass shell, SS coil

- Reflux line

- Gas mixture feeding circuit with control mass flowmeters

- Steam line with control valve

- 2 CO2 transmitter—analysers

- 12 temperature probes Pt100Ω

- Level detector (pressure transmitter)

- 2 manometers

- 2 CO2 analysers

- Differential pressure transmitter

Stirred Liquid-Liquid Extraction - ELA/100

Pignat's Stirred Liquid Liquid Extraction trainer (ELA/100) is a compact, benchtop unit that provides an in-depth, hands-on understanding of the basic, practical and theoretical elements of the liquid-liquid extraction process.

Liquid-liquid extraction is a fundamental material transfer operation in chemical engineering based on the varying solubility of the components of a mixture. It entails extracting a compound from a solution (solute dissolved in a diluent) by selective transfer to a second liquid (solvent), non-miscible with the first and with different densities.

The unit is used manually, with flows controlled by manual valves and flowmeters. The unit has a stirred glass column, which enhances the visual experience of the extraction process. Students will learn how to determine the interphase level, material balance, efficiency of the column, and more.

- Liquid-liquid extraction process in a stirred column

- Tabletop unit

- 2 polyethylene storage tanks, 9L

- 2 self-priming peristaltic pumps, variable speed

- Glass decanter with light phase outlet, heavy phase feeding

- Glass column

- Stirring device, composed of 20 SS Rushton type stirrer, variable frequency motor

- Glass decanter with heavy phase outlet, light phase feeding, draining column

- Inter-phase level setting system by lateral crosshead, setting from the ground

Pulsed Liquid-Liquid Extraction - ELL/4000

Pignat's Pulsed Liquid Liquid Extraction trainer (ELL/4000) is a standard-size, floor-standing unit that provides an in-depth, hands-on understanding of the basic, practical, and theoretical elements of the liquid-liquid extraction process.

Liquid-liquid extraction is a fundamental material transfer operation in chemical engineering based on the varying solubility of the components of a mixture. It entails extracting a compound from a solution (solute dissolved in a diluent) by selective transfer to a second liquid (solvent), non-miscible with the first and with different densities.

The unit is used manually, with flows controlled by manual valves and flowmeters. The unit has a 2"-diameter glass column, which enhances the visual experience of the extraction process. A pneumatic pulsator increases the contact between the two phases and mass transfer. Students learn how to determine the interphase level, material balance, efficiency of the column, and more.

- Study of pulsed liquid-liquid extraction process in a packed column

- Continuous process

- Gear pumps SS/PEEK head with integrated safety valve

- Glass decanter with heavy phase outlet, light phase feeding, and column draining

- Glass column, packing of Raschig glass rings

- Glass decanter with light phase outlet, heavy phase feeding, and column vent

- Pneumatic pulsator, PTFE bellows, double effect cylinder, stroke and frequency control

- Inter-phase level setting system by lateral crosshead, setting from the ground

- 2 float flowmeter

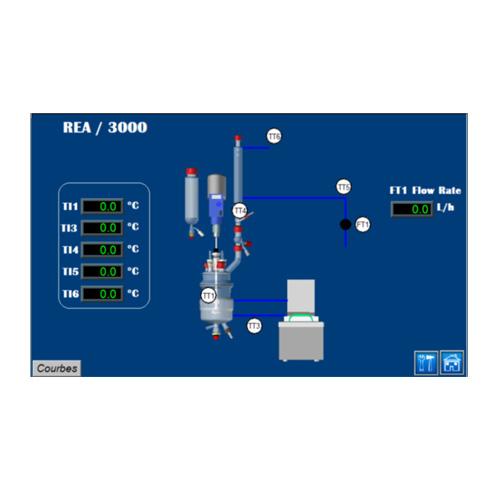

Computerized Chemical Reactor - REA/3000

Pignat's Computerized Chemical Reactor (REA/3000) is a one-gallon, controlled, multi-purpose, jacketed glass reactor system specifically designed for education and research. This unit supports the study of controlled batch chemical reactions and allows students to operate and experience reaction processes and modify the variables upon which the reactions being studied are based.

The unit demonstrates chemical synthesis in order to materialize multiple types of products. Temperatures and flows are measured and controlled using a convenient touch-screen interface. A thermostatic heating bath allows students to control the heating to the reactor. Glass components, including reactor and condenser, allow students to see the reaction process from beginning to end.

- Study of chemical reactions with various parameters

- Tabletop unit

- Data acquisition

- Glass reactor, jacketed, glass cover, reflux head with distillation valve

- Stirrer, SS/PTFE shaft and mobile

- Glass coil condenser, jacketed

- Glass reagent feed funnel, draining valve, and filling hole

- Heating group

- 5 temperature probes Pt100Ω

- Air flowmeter

- Water flowmeter

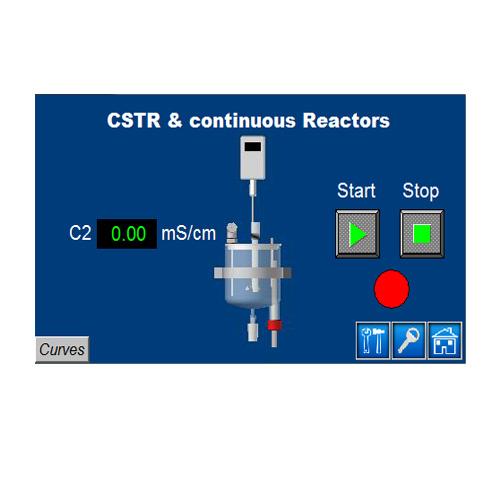

Flow of Fluids Unit (Continuous Reactors) - RAP/4000

Pignat's Flow of Fluids Unit (Continuous Reactors - RAP/4000) is a large-scale, modular, hydraulic network allowing for a broad range of experimental activities relating to the flow of an incompressible fluid (water) through piping systems.

This self-contained system facilitates study of pressure drop due to flow restrictions through valves, strainers, fittings, and pipe of varying diameters, different surface roughnesses, and lengths. The system also facilitates the study of flow rate measurement methods such as orifice assembly, venturi meter, variable-area flow meter, and by calibrated tank vs. time.

- Study and comparison of four continuous reactors from two different experiments:

- Monitor the dispersion (NaCl) in water for determination residence time

- The saponification of ethyl acetate by soda

- Two diaphragm pumps, variable flow rate

- Two glass vessels for constant feed by overflow

- Variable rate stirrer, SS stirring shaft with SS four blades helix

- 3 stirred glass reactors, pipe overflow, conductivity and temperature, drain valve and tracing injection: one 0.8L perfectly-stirred reaction vessel; and two 0.4L perfectly-stirred cascade vessels

- 2 plug glass reactors, 0.8L, conductivity and temperature measurement and tracer injection: one reactor coil, empty; and one reactor piston, packed

- 2 flowmeters

- 2 conductivity probes

- 2 temperature probes Pt100Ω