Important Product Note: Photographs are representative and for reference only. Product appearance and dimensions may vary based upon component manufacturer and availability. Any product dimensions given, such as size and weight, are approximate and for directional use only. For the most accurate shipping dimensions and weights, please contact the manufacturer.

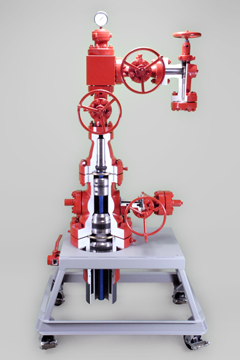

- Full-size steel construction throughout (all actual production components)

- Common wellhead components by well-known manufacturers selected for petroleum industry relevance

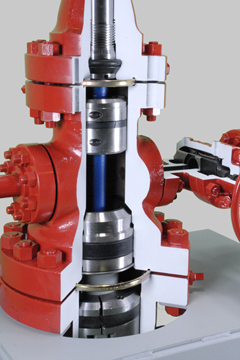

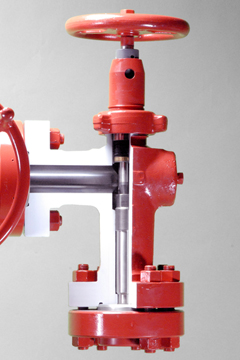

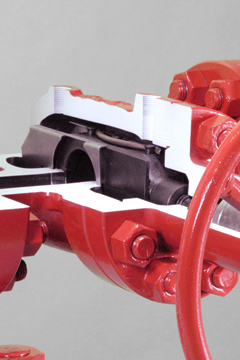

- Sectioning a all primary wellhead components (30-45 degrees approximately, removed)

- Powder-coating and/or painting using a high-durability enamel coating throughout

- Welded tubular steel and steel plate support stand, allowing for full visibility of above-ground and sub-surface components

- Four (4) high-capacity locking casters

- All hardware retained throughout

- Crating for shipment sea freight, or motor freight

- Product Dimensions

(L x W x H) 40in x 57in x 102in (1000 x 1450 x 2600 mm) - Shipping Dimensions

(L x W x H) (1) 59in x 45in x 82in (1500 x 1150 x 2100 mm), (1) 46in x 57in x 102in (1000 x 1450 x 2600 mm)

DISCLAIMER: Product Dimensions are approximate. Shipping Dimensions and Weights are for directional use only and may change based on manufacturer variables. For the most accurate Shipping Dimensions and Weights, please contact the manufacturer.

- Exploded-view technical illustration with component parts list

- Loose sample tubing head lock screw assembly