Staying Protected: Hands-On Transformer Training in Safe, Controlled Environment

To view a multimedia presentation of “Staying Protected: Hands-On Transformer Training in Safe, Controlled Environment”, please click here.

The life of a power line worker can be a precarious one. From maintaining interstate power grids to servicing transmission lines and towers, line workers are often tasked with jobs that aren’t for the faint of heart.

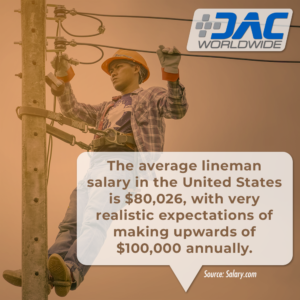

The profession is considered one of the most dangerous in America, with 35 fatalities in 2019 around the United States. The compensation for such an intimidating trade, though, is notable.

According to salary.com, the average lineman salary in the United States is $80,026, as of February 2021. The career offers very realistic expectations of making upwards of $100,000 annually before turning 25 for younger students.

Today, the career is becoming safer, thanks to developing safety technologies. There are Linemen Training Schools all over the United States and Canada, with many finding interest in the unique field of high-voltage electrical technology.

Despite the demands, it is critical for workers to be properly trained on the power that electricity holds, both physically and metaphorically. Due to its hazardous nature, becoming a lineman requires extensive technical knowledge and safety skills to help ensure worker safety.

In the past, teaching the ins and outs of transformers was primarily paper-based, with some programs even opting for full-voltage training. Most of the time, the “real” learning was done on-the-job.

But things have changed in the electrical technology field. Training future lineworkers no longer requires a book-only approach, or the dangers that come with full voltages. DAC Worldwide’s Transformer Connections Training System (413-000) is a utility worker training aid that provides learners with real-world, hands-on practice working with transformers.

What is the Transformer Connections Training System?

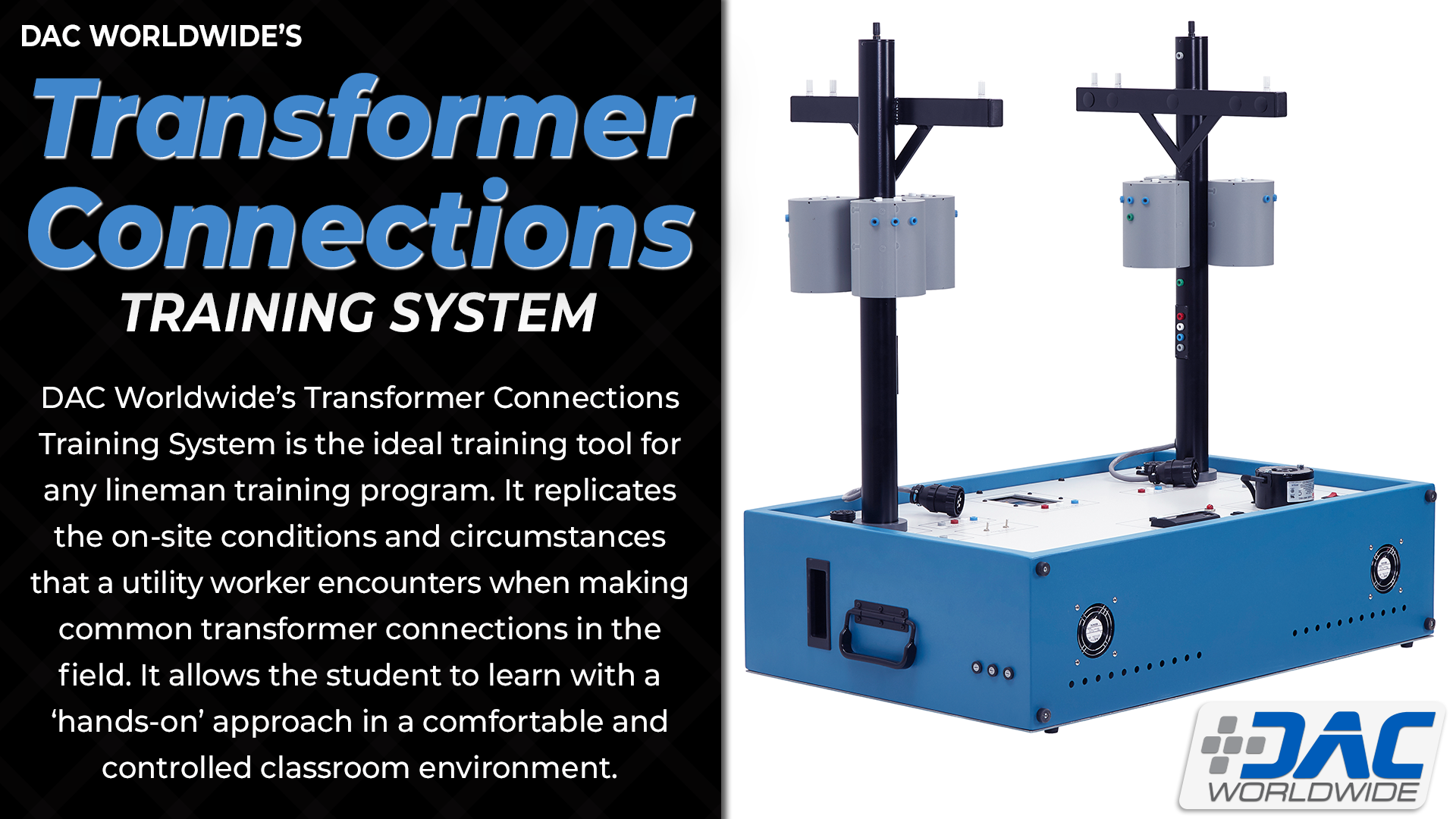

DAC Worldwide’s Transformer Connections Training System is the ideal training tool for any lineman training program. It replicates the on-site conditions and circumstances that a utility worker encounters when making common transformer connections in the field. It allows the student to learn with a “hands-on” approach in a comfortable and controlled classroom environment.

Gone are the days of full-voltage training and paper-based learning, as the training unit is internally fused and includes a recalibrated reduced-voltage meter to make training safe, efficient, and realistic. As students train on the system at 4100 VAC, for example, they will only be operating at 41 Volts. This allows them to see real line voltage without the potential of getting hurt.

Put together in a welded steel cabinet, the Transformer Connections Training System is wired for both single-phase and three-phase activities. It includes 14 transformer cans, which are wired with different configurations to allow for a variety of set-ups, as well as a panel-mounted voltmeter and a phase rotation meter. It requires a 208 VAC / 3-phase / 60Hz / 4-wire connection.

In addition to the hands-on approach, the Transformer Connections Training System includes a Student Training Manual with a variety of topics, like performing single-phase transformer connections, identifying 3-phase connections, and demonstrating how capacitors affect line voltage and current. Learners will also learn how to demonstrate parallel single-phase and 3-phase transformers, and other transformer-related topics and skills.

Other Transformer Training Products

In addition to the Transformer Connections Training System, DAC Worldwide also offers slightly different variation called the Transformer Wiring Training System (408-000). This training tool is ideal for future industrial electrical programs and electricians, as it covers a basic course on transformers. It can also be used in residential electrical programs, as the system also shows how to connect a residential service.

Like the 418-000, the Transformer Wiring trainer takes the safe approach in learning by using low-voltage outputs while simultaneously simulating high-voltages. It replicates the single-phase transformer connections, as well as both delta-wye 3-phase transformer connections. All of the transformers are the same, and build into the unit, with the middle representing six different generators.

Students will be able to demonstrate proper installation of ground connections, primary and secondary side connections, and parallel transformer connections. The system also includes eight built-in instructor fault switches, which simulate failure conditions and allow real-time assessment and troubleshooting for students.

In addition to training systems, DAC Worldwide also offers two Transformers cutaways: one depicting a single-phase transformer, with the other showcasing a three-phase. Cutaways are real-world industrial components that have been restored, cut away, and refinished using durable urethane coatings. Each of these industrial components has been professionally sectioned to expose each device’s primary components, with functionality completely retained.

The Single-Phase Transformer (273-912) highlights a common shell-type, single-phase transformer found in manufacturing facilities and refineries, among others. The Three-Phase Transformer Cutaway (273-915) features a common coaxially-wound, three-phase, delta-wye transformer found in various industrial and commercial applications.

How Can DAC Worldwide Help Your Training Program?

With more than four decades of experience in industrial training, DAC Worldwide’s reach extends far beyond just electrical products. In fact, DAC Worldwide possesses knowledge and expertise in a wide range of technical topics, including Electronics, Fluid Power, Heat Transfer & Steam, HVAC, Machining & Measurement, Mechanical Drives, Oil Production, Process Control & Instrumentation, and Pumps, Compressors & Valves.

Our training aids range from training systems and sample boards, to models and dissectibles – with real-world, hands-on learning being the core of each product. For more information on how DAC Worldwide can enhance your industrial training program and provide you with the best training solutions available, please click here.

- Published in News

Building a Mechanical Drives Training Program | Amatrol & DAC Worldwide Offer Complementary Training Solutions

To read ‘Building a Mechanical Drives Training Program’ as a Multimedia presentation, please click here.

Essential workers come in all shapes and sizes.

Without properly functioning mechanical drives, robots wouldn’t be able to perform automated commands, conveyor belts would lay still, and machining centers would grind to a screeching halt. Machine breakdowns couldn’t be fixed without them.

Local industry needs more technicians with specific skillsets, including proficiency in working with mechanical drives. What’s needed are more in-depth programs that not only provide hands-on skills, but take learning beyond the classroom with full, interactive eLearning.

With traditional education facing unprecedented uncertainty, building a sought-after Mechanical Drives Training Program is becoming a high priority for high schools and colleges around the nation. And thanks to Amatrol and its new sister company, DAC Worldwide, constructing a dream Mechanical Drives Training Program is now easier than ever.

What Good Comes With Mechanical Training?

Frankly, mechanical drives are found in almost every aspect of life and countless industrial sectors, such as agriculture, pharmaceuticals, automotive, construction, power & energy, industrial maintenance, mining, and more.

Thanks to its worldwide use, mechanical maintenance technicians are highly sought after. Positions are available, with more on the way thanks to a large chunk of Baby Boomers approaching retirement age.

However the importance behind mechanical training can eventually be attributed to the impending Skills Gap, which has the potential of leaving millions of jobs unfilled due to a lack of qualified workers. Thanks to equipment that is becoming more technologically advanced by the day, few can perform routine maintenance that must be learned and practiced to gain proficiency.

Today, mechanical maintenance technicians are expected to possess a very specific, highly technical skillset. So in order to meet those expectations, current mechanical training should cover everything from bedrock fundamentals, all the way through advanced manufacturing applications.

In addition, the training should not be one-dimensional. While hands-on training allows students to take a more tangible approach to training, theoretical understanding of the topic brings the knowledge full circle. One without the other would be doing a disservice to not only the students, but any customers they may encounter on their professional journey.

How DAC Worldwide & Amatrol Can Legitimize Your Mechanical Drives Training

No matter how advanced your mechanical drives training may (or may not) be, Amatrol and DAC Worldwide can add the substance to take your program to the next level.

DAC Worldwide and Amatrol joined forces in 2019 after discovering that their training systems complemented each other to create an ever more robust training. As worldwide leaders in technical training, the goal of the “sister companies” was to provide even more technical training opportunities for schools and companies in need, especially in the field of mechanical drives.

However the real winners in the combining of these two technical training companies? The learners. While Amatrol and DAC Worldwide may be in the forefront of technical training, the approach taken by the two companies varies slightly.

What this means is even more opportunities for learners to strengthen their skills before entering the workforce. It also gives schools and training facilities more options when building their program, as Amatrol’s and DAC Worldwide’s products complement each other for a well-rounded classroom.

For example, Amatrol has unmatched eLearning curriculum, as well as unparalleled depth and breadth of coverage. The learning systems, which are available in both portable and full-size models, offer thorough, in-depth training that can be added on as training needs grow or change. A typical lesson will see students start with the basics, like identification and definition, before moving on to more challenging topics, like troubleshooting and implementation.

DAC Worldwide, on the other hand, creates training systems, models, cutaways, and sample boards of various mechanical drives. Each product is intended to train students on a specific set of technical topics. So if instructors have a particular skill they have identified as the most appropriate – like belt drive training (201-000) – a DACW training system will focus solely on that particular skill. Or for those that need a perfect tool for skill evaluation for pre-hire or annual skill testing, DAC Worldwide’s products would be the ideal solution. In turn, with its focused scope, these trainers could be a less expensive alternative to large-scale systems.

Amatrol and DAC Worldwide Mechanical Training Solutions

As mentioned, both Amatrol and DAC Worldwide provide mechanical training, but do so in slightly different, yet complementary, closely-aligned ways that further enhance training.

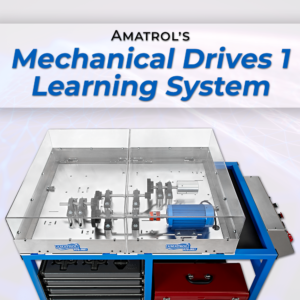

Amatrol built a platform that has a broad range of skills on its base levels, with the opportunity for expansion. By adding an optional system, users can create a system that is unmatched in its depth and breadth of training. Amatrol’s Mechanical Drives 1 Learning System (970-ME1) does it all in a compact system and also includes interactive eLearning.

DAC Worldwide, on the other hand, built individual systems that focus on more specific skill training. Users can easily expand the number of trainers used for more in-depth skill-building, or use the trainers as a tool for learners’ final assessment. It’s also ideal for adult training, if local industry wants their employees to have specific training, such as coupling alignment (206-000), without the need for belts, chains, and other components.

While both approaches lead to successful technical training, many of DAC Worldwide and Amatrol’s products work hand-in-hand for seamless integration into any Mechanical Drives program.

So if you’re looking for a way to expand (or begin) a Mechanical Drives Program, here are a few solutions on how to implement trainers from both DAC Worldwide and Amatrol:

Solution #1: Mechanical Drives Learning System | 970-ME1 (Amatrol)

The “crown jewel” of mechanical training products, Amatrol’s 970-ME1 covers countless industry-needed skills in one convenient system. The Mechanical Drives 1 Learning System covers alignment and operation of mechanical drives, and alignment and applications of various motor drive systems.

Accompanied with online mechanical drives curriculum to gain theoretical knowledge, this system also provides hands-on skill training for shaft, belt, gear, and chain drives using real-world motor drive components. Students will cover topics like mechanical drive systems, key fasteners, power transmission system, v-belt drives, and much more.

With the 970-ME1, Amatrol expertly mixes theoretical concepts immediately followed by hands-on practice to build the strongest possible retention and competency for learners. It includes Amatrol’s world-class eLearning curriculum, as well as expansion units to further training, such as:

- Mechanical Drives 2

- Mechanical Drives 3

- Mechanical Drives 4

- Laser Shaft Alignment*

- Vibration Analysis*

- Roller-Pack Machine Tool Axis

- Plain Bearing Machine Tool Axis

- Floor-Standing Belt Conveyor

- Machine Tool Chip Conveyor

- Predictive Maintenance Vibrations Analysis

* Also Available as Stand-Alone Training System

Solution #2: Single-Topic Trainers (DAC Worldwide)

Single-topic trainers focus on one core subject matter, making it useful for applications where there is a greater need for training on a specific topic. Not only can these DACW trainers extend your training lab to accommodate more students at a very low cost, but they can add to Amatrol’s 970-ME1 system.

Belt & Chain Drives

DACW’s Belt Drive Training System Plus (201-PAC) focuses on the identification, installation, tensioning, and alignment of common belt drives types found throughout industry. It includes flanged bearings, fractional horsepower belts and sheaves, multiple Type-A belt sets, sheave bushings, and more.

Available in: 201-000, 201-PAC

The Chain Drive Training System Plus (223-PAC) presents learners with industrial chain drives, heavy/silent chains, and sprocket set usage, providing a complete introduction to chain nomenclature, assembly, disassembly alignment, and maintenance.

Available in: 223-000, 223-PAC

Gear & Bearing Maintenance

DAC Worldwide’s Gear Maintenance Training System Plus (205-PAC) is the ideal training tool to learn how to install, align, troubleshoot, and repair a wide variety of gears, shafts, and bearings. Learners will be introduced to gear identification, installation, alignment, and troubleshooting.

Available in: 205-000, 205-PAC

The Advanced Bearing Maintenance Training System Plus (204E-PAC) allows for in-depth training in the identification, installation, and removal of various industrial-quality rolling element bearings. Using two workstations, students will study topics such as bearing identification systems, rolling element bearing construction, bearing maintenance pre-check, and more.

Available in: 204E-000, 204E-PAC

Coupling / Shaft Alignment

For convenient, realistic training in shaft alignment, look no further than DAC Worldwide’s Basic Coupling / Shaft Alignment Training System Plus (208D-PAC). The design is based on the configuration found in many vertical centrifugal pumps, and accommodates all types of alignment apparatus, including laser systems. Learners will perform four-point motor element jacking, master a dial indicator in coupling/shaft alignment, troubleshoot angular and parallel misalignments, and install a flexible disc coupling.

Available in: 208D-000, 208D-PAC

Brake Clutch

Using a completely motorized training package of brake and clutch-related hardware and control components, DACW’s Brake Clutch Training System (220-PACP) explores how brakes and clutches are used for training throughout various sectors. The trainers covers the installation, operation, and troubleshooting of brakes and clutches in a variety of applications.

Using a completely motorized training package of brake and clutch-related hardware and control components, DACW’s Brake Clutch Training System (220-PACP) explores how brakes and clutches are used for training throughout various sectors. The trainers covers the installation, operation, and troubleshooting of brakes and clutches in a variety of applications.

Available in: 220-000, 220-PACP

Solution #3: Enhancement Trainers (DAC Worldwide)

In addition to single-topic trainers, DACW also offers Enhancement Trainers.

Basically, Enhancement training systems cover skills that are not currently included in Amatrol training systems, specifically the 970-ME1. These units have the same look and feel as single-topic trainers, but can extend the training capabilities of Amatrol mechanical learning systems.

Advanced Coupling / Shaft Alignment

DAC Worldwide’s 3-Component Coupling Shaft Alignment Training System Plus (206-PAC) is patterned after a typical turbine-driven pump or turbo-compressor. The system includes flanged bearings that allow changes in angular and parallel misalignment, motor attachment points with steel-threaded inserts, and replaceable shaft for easy installation of bent shafts.

Available in: 206-000, 206-PAC

With a design based on the configuration found in many vertical centrifugal pumps, DACW’s Vertical Coupling / Shaft Alignment Training System Plus (207-PAC) features industrial-grade components to perform a four-point motor element jacking, install a flexible disc coupling, and troubleshoot angular and parallel misalignments.

Available in: 207-000, 207-PAC

Fan Balancing

DAC Worldwide’s Fan Balancing Training System Plus (202-PAC) encourages learners to gain experience with fan balancing in an effort to achieve maximum fan efficiency and stability. Designed to look and perform like a typical squirrel cage fan, it comes with movable pillow block assemblies and can feature even or odd number blade configurations.

Available in: 202-000, 202-PAC

Vibration Analysis

Using DACW’s Vibration Analysis Training System Plus (203-PAC), students will be introduced to a versatile, precision-machined device that isolates individual, vibration-causing variables in order to demonstrate their individual signatures. Topics include effects of frequency/displacement, proper pick-up mounting, correcting vibrations caused by imbalance and misalignment, and more.

Available in: 203-000, 203-PAC

Advanced Bearing Maintenance

The Journal and Fluid-Film Bearing Training System Plus (204J-PAC) trains learners in the identification, installation, removal, and maintenance of a variety of Babbitt-type journal bearings found on high horsepower, high-speed rotating machines. Using two workstations, students practice common maintenance tasks, such a bluing check, dent repairs, and hand scraping.

Available in: 204J-000, 204J-PAC

Let Amatrol and DAC Worldwide Help You Build Your Ideal Mechanical Training Program

No matter what kind mechanical training you’re looking for, or what skills you’d like to focus on, the world-class training tools of Amatrol and DAC Worldwide should have you covered. With almost 80 combined years of technical training experience, no other company on the market can match us!

For more information on how to build your ideal mechanical training program, please click here.

- Published in News

5 Skills Every HVAC Technician Should Possess

To view ‘5 Skills Every HVAC Technician Should Possess’ as a Multimedia Presentation, please click here.

While the national unemployment rate might be near all-time lows (3.5-percent in Dec. 2019), one industrial job is expected to grow by more than 46,000 jobs over the next decade: HVAC technicians.

Thanks to a push of commercial and residential building construction that is expected to drive employment growth and job opportunities, the employment outlook is expected to increase by 13-percent over the next 10 years. That is a sizable leap from the national average for all occupations, which sits at 5-percent over the next 10 years.

Thanks to a push of commercial and residential building construction that is expected to drive employment growth and job opportunities, the employment outlook is expected to increase by 13-percent over the next 10 years. That is a sizable leap from the national average for all occupations, which sits at 5-percent over the next 10 years.

Not only are there currently enough jobs to go around, but a spike in upcoming retirements has some employers desperate for qualified talent. That’s good news for those interested in joining the HVAC field, as it places them firmly in the driver’s seat of finding an ideal professional match.

So with jobs aplenty, what skills are employers most focused on when hiring HVAC technicians? DAC Worldwide, a company with 40 years of experience working with industry and technical education, has compiled a list of the five most meaningful HVAC technician skills companies are in search of:

1. In-Depth Knowledge of HVAC Systems and Methods

Doctors know medicine. Car mechanics know cars. To be successful in a profession, employees must understand the craft inside and out.

HVAC technicians are no different. They are responsible for knowing about a wide range of HVAC systems, controls, and installation methods, and quite literally, need to know about everything from hot to cold.

Whether technicians are threading and installing gas piping, or laying out duct systems, a deep understanding of all things HVAC is critical. Not only should technicians have the hands-on skills to perform each task, but they should back that up with a strong theoretical knowledge of their subject.

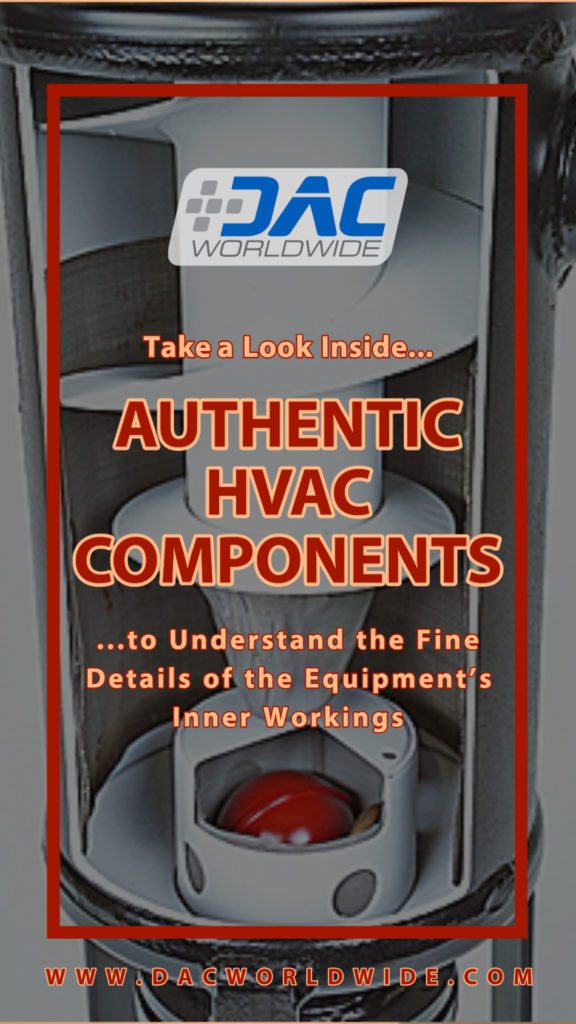

One way to enhance the understanding of HVAC systems is by taking a deep dive into how each piece of equipment works along the process. DAC Worldwide, for example, produces full-size industrial component cutouts that allow learners to take a peek inside real HVAC equipment for the first time. Now, students can see inside the equipment they might be fixing firsthand, providing an unparalleled training tool.

Today’s HVAC systems can be assembled, disassembled, repaired, and programmed, so having a background of mechanical skills is a key component to building a successful technician career. (After all, the more technical knowledge that a technician has from the start, the faster they can learn new skills, an attribute companies consider to be highly valuable.)

2. Acute Troubleshooting and Problem-Solving Skills

The goal for every HVAC technician is the same – aim for safe, timely, and effective services every time. In order for that to happen, techs need to be quick-thinking workers, equipped with a collection of problem-solving techniques, and possess familiarity with the latest diagnostic and testing equipment.

The goal for every HVAC technician is the same – aim for safe, timely, and effective services every time. In order for that to happen, techs need to be quick-thinking workers, equipped with a collection of problem-solving techniques, and possess familiarity with the latest diagnostic and testing equipment.

In just one work day, technicians may face a wide variety of issues: one customer may have total system failure, while another is dealing with noise issues, or temperature balancing problems. Being able to quickly size-up the problem, identify solutions, and implement a resolution is the key to finding success as an HVAC technician.

Problem-solving is impossible without an acute attention to detail. So along with ingenuity, employers are also looking for workers that are detail-oriented. Not only should technicians be able to track the work they are completing, but they should also be aware of the intricacies of the equipment they are working on. Sometimes, not paying attention to the details could be costly – either to the equipment, or the technician’s safety. Effective troubleshooting is a combination of accepted troubleshooting procedures supported by a solid knowledge of how these systems work to perform their operations.

Thanks to using real-world components, DAC Worldwide’s HVAC cutaways take detailed training to another level. By providing a look inside authentic components found in HVAC systems worldwide, learners can truly understand the fine details of the equipment’s inner workings. To truly understand how a component can fail, technicians must first understand how it works.

3. Extensive Knowledge of Safety Standards and Protocols

A day in the life of an HVAC technician is not exactly a walk in the park.

According to the U.S. Bureau of Labor Statistics, technicians have one of the highest rates of injuries and illnesses of all occupations. While most of these can be prevented by following safety protocols, it does have the potential to be a dangerous career.

So despite working heights, in confined spaces, or attached to scaffolding, having comprehensive knowledge of proper preventative safety standards can keep workers healthy and business moving. From hazardous tasks like lifting heavy objects to installing electric wires and controls, understanding personal protective equipment (PPE) and other safety codes could be the difference between technicians suffering an injury, or not.

On top of personal safety, HVAC technicians need to be well-versed in government regulations. The U.S. Environmental Protection Agency (EPA), for example, requires that all technicians who work with refrigerants be certified in proper refrigeration handling. There are additional regulations on how to handle pressurized gases, refrigerants, and other toxic or hazardous materials, so knowing regulations surrounding proper and safe disposal will not only protect technicians from an accident or injury, but will also keep clients and the environment safe.

4. Soft Skills, Communication, and Flexibility

Whether it’s a personal relationship or professional contact, we’ve all heard about the importance of first impressions: You only get one, so make it count.

Whether it’s a personal relationship or professional contact, we’ve all heard about the importance of first impressions: You only get one, so make it count.

Having a clean, professional appearance, listening to the customer, and showing all-around common courtesy are essential skills that can make or break a first meeting. Out in the field, employees are the face of the company, so making a good first impression is crucial for success of the business.

Possessing natural Customer Service skills are equally as important to this career as the technical skills a technician has. Not only is it a tech’s job to explain repairs and answer questions in a non-technical way, but they need to make the clients feel comfortable, building trust and rapport. This might require a little patience too, as their issues might have been ongoing, and frustration may be mounting. But in the end, having the ability to calmly and professionally talk through all of the issues and potential solutions will put everyone at ease.

Finally, in the world of an HVAC technician, every day is a new adventure. No matter the season, HVAC technicians are expected to work, even in uncomfortable situations.

Sometimes it’s too hot because the air conditioning isn’t working – other times the heat is out, making work conditions frigid. Even in the dead of winter, technicians might have to work outdoors, fixing heat exchanges, for example. Taking ‘flexible’ in a much more literal sense, some units are located in tight spaces, forcing technicians’ bodies to bend and curve in positions they didn’t know it could.

Being flexible is just part of the game. In this line of work, “That’s not my job” doesn’t exist. Sometimes, just being able to make changes on a whim, and occasionally just rolling with the punches, are the most effective tools a technician needs in his or her arsenal.

5. Willingness to Continue HVAC Learning and Training

If smart devices have taught us anything, it proves how quickly (and drastic) technology can change over decades. From minor tweaks to major overhauls, each update includes newer options and faster speeds.

The HVAC industry is no different. While it may not move with the veracity of cell phone technology, tools and equipment are being continuously adjusted to run more efficiently.

Today, there is also a continued push for greater energy efficiency, which includes phasing out hydrofluorocarbons (HFC) in favor of Global Warming Potential (GWP) refrigerants, and a rise of “zero emission building plans” and other green building standards. Soon, the HVAC industry will see an increase of variable speed technologies, which will improve electrical efficiency, air quality, and humidity control.

Without continued re-training within the field, technicians run the risk of encountering a component they can’t fix. So by having the willingness to continually hone their skills will not only be beneficial to their future professional success, but will also ensure timely, safe repairs and installations for all parties involved.

- Published in News