- 7-Gauge, formed-steel, powder-coated baseplate

- Provisions for tabletop mounting, and mounting on related DAC, workstation and bench products.

- Aluminum T-slotted mounting rail area, allowing for attachment of motor, coupling guards, as well as standard and optional brakes and clutches

- 16-Gauge, formed-steel control assembly support structure, allowing for integration with control components

- 16-Gauge, formed-steel, electrical enclosure, with provision for attaching front panel face

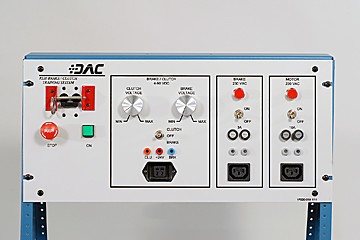

- Powder-coated and epoxy silk-screened, 1/8" aluminum, front panel face

- Keyed, instructor power switch (rear of enclosure)

- Two-pole, panel-mounted, circuit breaker with provision for lock-out/tag-out

- Pilot light and emergency stop switch

- Two (2) Variable-DC controls allowing adjustment of both brake and clutch functions. (Banana jack connections allow for control and sequencing via external or optional control devices. Fused brake and clutch AC supplies with contacts for external control.)

- Dedicated brake, motor, and DC control connecting cables

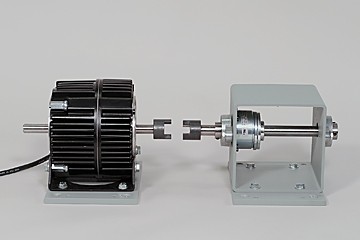

- 1/3 HP Dual voltage motor assembly

- Electromagnetic brake/clutch assembly. (56-frame), with powder-coated aluminum mounting plate

- DC tensioning brake assembly

- Two (2) Jaw and spider (Lovejoy) couplings

- Two (2) Formed-polycarbonate, modular, re-positionable, coupling guards

- Provision for mounting all components on related DAC Electromechanical IntergrationBench products

- Packaging for shipment via motor freight

Package Includes:

- #220 - Brake Clutch Trainer

- #220-001 - Programmable Micro-Controller Panel Assembly

- #220-006 - Pneumatic Supply Control and Distribution Panel Assembly

- #330-011 - Abbreviated Toolkit

DISCLAIMER: Product Dimensions are approximate. Shipping Dimensions and Weights are for directional use only and may change based on manufacturer variables. For the most accurate Shipping Dimensions and Weights, please contact the manufacturer.

- Product Dimensions

47.5in x 13.5in x 25in (1207 x 343 x 635 mm)

148 lbs (67 kg) - Shipping Dimensions

50in x 15in x 40in (1270 x 381 x635 mm)

217 lbs. (98 kg)

- 100-240 VAC

- 50/60 Hz, single-phase