- Allows for two student workstations

- Requires 204-001 Tool Kit

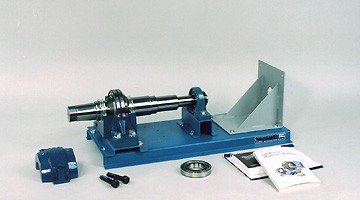

- CNC-machined, 24” long, multi-land shaft

- Large-diameter spherical roller bearing pillow block and radial ball bearing pillow block for mounting on land shaft

- 7-Gauge, formed-steel baseplate, 30" long, allowing for mounting across the width of a standard shop bench

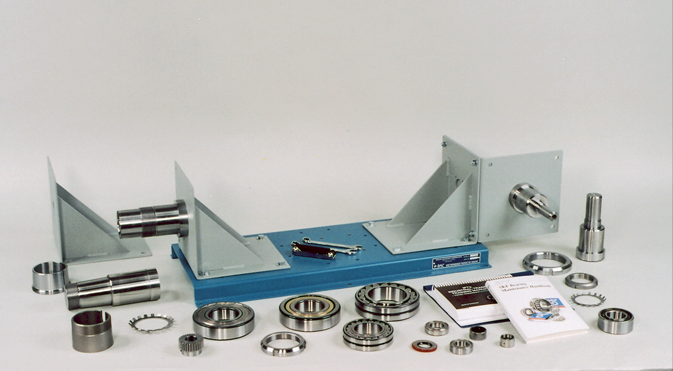

- Four (4) steel shaft mounting brackets which, when used in combination, allow for mounting of shafts in different orientations

- Four (4) high-grade alloy steel CNC-machined stub shafts allowing for installation of all bearings

- Provision for installation of radial ball bearings and cylindrical roller bearings with loose and interference-fit applications

- Provision for installation of spherical roller bearings on a tapered shaft, adapter sleeve and withdrawal sleeve. (Includes two different internal clearance calculations.)

- Provision for installation of a radial ball bearing in an externally-seated application

- Provision for bearing removal using a gear puller on a back-up gear

- Eight (8) bearing types for mounting on stub shafts

- Shaft seal application

- High-durability, powder coated surfaces throughout

- Combination wrenches

- Allen wrench set

- Use/Exercise Guide

- Industrial Trades Training Manual (IPT)

- Reference book on bearing maintenance (SKF)

DISCLAIMER: Product Dimensions are approximate. Shipping Dimensions and Weights are for directional use only and may change based on manufacturer variables. For the most accurate Shipping Dimensions and Weights, please contact the manufacturer.

- Product Dimensions

(L x W x H)

30" x 13 1/2" x 12" (750 x 330 x 300 mm)

170lbs. (77kg) - Shipping Dimensions

(L x W x H)

34" x 15" x 24" (870 x 380 x 610 mm)

290 lbs. (132 kg)

- #099-00S - 6-Topic Power Transmission Installation and Maintenance Training DVD (IBT)

- #204-004 - Extended Bearing Fitting Tool Kit

- #510-000 - IPT Industrial Trades Training Manual

- #510-001 - IPT Industrial Trades Handbook

- #835 - Bearing Sample Board

- #902F - Electromechanical Workstation

- #204-006 - Hydraulic Installation/Removal Option

- #204-500 - Use/Exercise Guide (additional)

- #204-001 - Toolkit

- #204-002 - Bearing Heater

- #204-005 - Bearing Inner Race Puller Tool

The courseware, useful in both an instructor-led or self-directed format, includes a textbook with chapters on rolling element bearings and friction bearings, and seventeen, illustrated, hands-on exercises.

Exercises include:

- Introduction to rolling element bearing construction and terminology

- Introduction to rolling element bearing types

- Introduction to bearing identification systems

- Introduction to bearing clearances and fits

- Bearing maintenance pre-checks

- Cold mounting and removal of radial ball bearings

- Mounting and dismounting of radial ball bearings with interference fits

- Installing and dismounting a radial ball bearing with a back-up gear

- Installing and dismounting angular contact bearings

- Mounting and dismounting of spherical roller bearings on a tapered shaft

- Mounting and dismounting of spherical roller bearings on a tapered sleeve

- Mounting of spherical roller bearings on a withdrawal sleeve

- Installation of pillow block bearings

- Installation of externally seated radial ball bearings

- Installation of cylindrical roller bearings using an arbor press

- Installation of shaft seals

- Hydraulic mounting and dismounting of tapered bore bearings (supplemental)