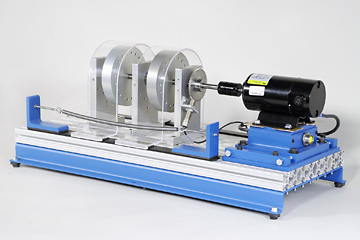

- 1/3 HP, 3450 RPM, inverter-duty, 3-phase, AC motor

- SCR speed control

- Digital RPM indicator with magnetic pick-up

- Heavy-duty, formed-steel sub-base with adjustable feet

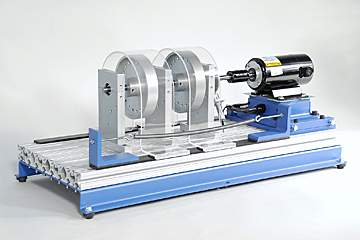

- Three (3) precision-machined split pillow blocks, allowing for bearing removal

- Two 6" precision-machined rotors, allowing for single plane, dual plane and overhung balancing

- Provision for creating rotor imbalance using set screws/washers or clay on inner rotor rim

- Three ½" diameter, precision-ground shafts, which allows for re-configuration

- Precision, helical beam coupling (Other coupling types available as options)

- Provision for attachment of vibration pick-ups via 1/4-28 threaded studs

- Steel top-surface mounting bars allowing for attachment of accessories, and modular guards

- Instructor key switch

- Motor mounting sub-base with tapered alignment pins, allowing for ease of alignment/mis-alignment

- T-slotted aluminum mounting surface allowing for convenient reconfiguration, and attachment of optional accessories

- Motor jacking bolts

- High-durability powder-coated and anodized surfaces throughout

- Modular polycarbonate guards

- Packaging for shipment via motor freight

DISCLAIMER: Product Dimensions are approximate. Shipping Dimensions and Weights are for directional use only and may change based on manufacturer variables. For the most accurate Shipping Dimensions and Weights, please contact the manufacturer.

- Product Dimensions

(L x W x H)

13.5" x 30" x 13" (343 x 762 x 330 mm) - Shipping Dimensions

(L x W x H)

41" x 37" x 32" (1041 x 940 x 813 mm)

168 lbs (76 kg)

115V/60Hz/1Ph power