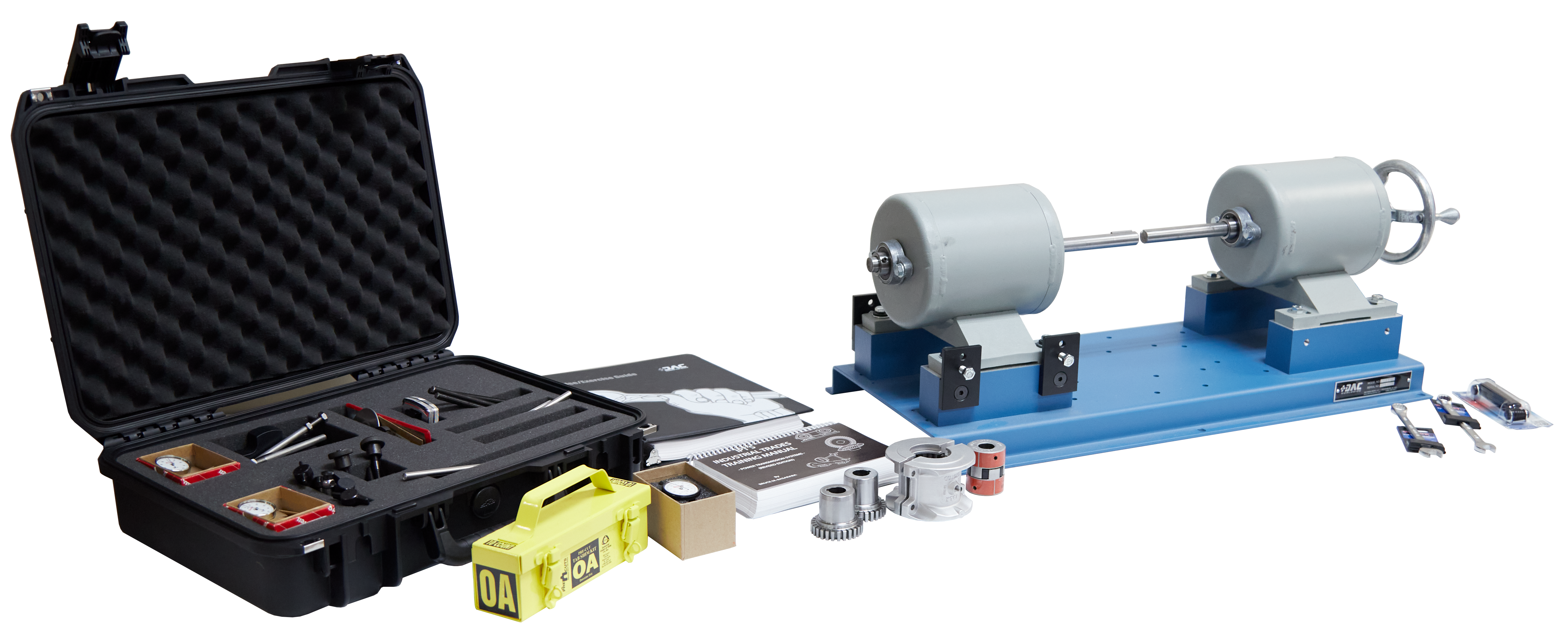

- 7-Gauge, formed-steel baseplate.

- Heavy-duty, welded aluminum driver and driven elements.

- Allows for alignment using all common methods and alignment tools.

- Multiple "motor" positions allow for use of many coupling types.

- Dimensions based on a common ANSI centrifugal pump.

- Rigid construction allows alignment to .001".

- Requires a minimal number of hand tools.

- Flanged bearings allow changes in angular and parallel misalignment.

- All fasteners easily accessible and replaceable.

- Motor attachment points include steel threaded inserts.

- Replaceable shafts. Bent shafts are easily installed.

- 3/4" Diameter shafting with keyways.

- Uses size "A" shims.

- High-durability, powder-coated surfaces allow for repeated use and rough handling.

- Can be used with or without jacking bolts.

- All components can be mounted on related bench and workstation products.

- Packaging for shipment via motor freight.

The courseware, useful in both an instructor-led or self-directed format, includes a textbook with chapters on couplings and alignment technique, and twenty, illustrated, hands-on exercises.

Exercises Include:

- Exercise 208-S01 - Introduction to Coupling/Shaft Alignment Terminology and Theory

- Exercise 208-S02 - Use of a Dial Indicator in Coupling/Shaft Alignment

- Exercise 208-S03 - Coupling Alignment Pre-Checks

- Exercise 208-S04 - Locating and Correcting Soft Foot

- Exercise 208-S05 - Calculating and Correcting for Bar Sag

- Exercise 208-S06 - Coupling Alignment Using a Straightedge and Thickness Gage

- Exercise 208-S07 - Coupling Alignment Using the Rim and Face Method

- Exercise 208-S08 - Using Graphical Solution Techniques With the Rim and Face Method

- Exercise 208-S10 - Coupling Alignment Using The Reverse Dial Indicator Method (Two Dials)

- Exercise 208-S11 - Using Graphical Solution Techniques With the Reverse Dial Indicator Method

- Exercise 208-S12 - Coupling Alignment Using The Reverse Dial Indicator Method (One Dial)

- Exercise 208-S13 - Considering Thermal Growth in Shaft Alignment

- Exercise 208-S50 - Inspection and Installation of Shafts and Keyways

- Exercise 208-S51 - Fabrication and Installation of Shaft Keys

- Exercise 208-S53 - Assembling and Installing a Chain-Type Coupling

- Exercise 208-S57 - Assembling and Installing a Jaw and Spider Coupling

- Exercise 208-S58 - Assembling and Installing an Elastomeric Element Coupling

- Exercise 208-S60 - Assembling and Installing a Flexible Disc Coupling

- Exercise 208-S61 - Assembling and Installing a Steel Grid Coupling

- Exercise 208-S62 - Assembling and Installing a Universal Joint Coupling

- Four steel pads for use with jacking bolts.

- Allen wrench set.

- Combination wrenches.

- Industrial Trades Training Manual (IPT).

- Use/Exercise Guide with 20 hands-on exercises.

DISCLAIMER: Product Dimensions are approximate. Shipping Dimensions and Weights are for directional use only and may change based on manufacturer variables. For the most accurate Shipping Dimensions and Weights, please contact the manufacturer.

- Product Dimensions

(L x W x H)

30in. x 13in. x 16in. (760 x 330 x 400 mm)

45lbs. (20kg) - Shipping Dimensions

(L x W x H)

34in. x 15in. x 24in. (870 x 380 x 610 mm)

93lbs. (48kg)

- Recommended #902F - Electromechanical Workstation

- #208-001 - Tool Kit, Shaft Alignment

- #208-003 - Standard Shim Kit

- #208-004 - Extended Shim Kit

- #208-005 - Steel Grid Coupling, Coupling/Shaft Alignment

- #208-006 - Thomas Flexible Disk Coupling, Coupling/Shaft Alignment

- #208-007 - Elastomeric Element Coupling, Coupling/Shaft Alignment

- #208-012 - Chain Coupling, Coupling/Shaft Alignment

- #208-013 - Universal Joint Coupling

- #208-014 - Jaw and Spider Coupling, Coupling/Shaft Alignment

- #208-020D - Basic Laser Alignment System

- #510-000 - Industrial Trades Manual (IPT)

- #510-001 - Industrial Trades Handbook (IPT)