DAC Worldwide Provides Unique Oil & Gas Training Tools

From operators and technicians to mechanics and engineers, oil and gas workers need knowledge and hands-on skills related to a wide variety of common industrial components they’ll encounter in the field. For example, a typical oil and gas worker will interact with a range of pumps and valves on a daily basis.

One such component workers will need to understand is a type of valve known as a back pressure regulator. Back pressure regulators are normally closed valves that precisely control and limit the upstream pressure in a system.

Back pressure regulators maintain a steady upstream pressure of any fluid, gas, liquid, or mixture in a system. They regulate system pressure by adjusting position, widening or narrowing to relieve or increase pressure. Usually installed at the end of a line or process, back pressure regulators ensure that all equipment used before the back pressure regulator receives the correct pressure, maintaining the integrity and effectiveness of the process.

When used in a well head, back pressure regulators control the flow of fluids or gases in the well. The back pressure regulator opens or closes with changes in the pressure of the fluid or gas, preventing overpressure within the well and protecting equipment and personnel from damage or injury. A wellhead back pressure regulator can also be used to maintain a specific pressure in a well for production or injection operations.

To teach oil and gas workers about these common components, DAC Worldwide’s Wellhead Backpressure Regulator Cutaway (295-703) is a sectioned specialty regulator sample that provides convenient classroom and laboratory training in the operation, construction, and maintenance of three industrial back pressure regulator (BPRs), as used in gas and oil service in the oilfield.

These common regulators are often used to maintain steady pressure on an oil column or to assure continuous flow of a producing low pressure well. They’re also regularly found in Xmas tree assemblies in the oilfield.

Through carefully planned sectioning and color-coding, the complete internal configuration of the regulating valve is exposed and showcased. Seal features and hardware locations have been retained, allowing for hands-on training in maintenance. These valves, commonly used in oil & gas production applications and commonly encountered in production wellheads and Xmas trees, are an essential part of comprehensive oil and gas production training.

The Wellhead Backpressure Regulator Cutaway is only one of DAC Worldwide’s many oil and gas training tools. Visit DAC Worldwide online to learn more about other oil and gas training aids, such as the Diaphragm Dump Valve Cutaway, Piston Check Valve Cutaway, Vertical Separator Trainer, and many more!

- Published in News

Hands-On Training Essential for Nation’s Utility Workers

Click HERE to view Hands-On Training Essential for Nation’s Utility Workers as a multimedia presentation.

Do you ever daydream about going “off the grid”? For many, the thought of unplugging for an extended time away from life’s troubles sounds refreshing.

The reality underlying this common dream of escape is how thoroughly tied our lives are to the grid. What would our everyday routines be like without the utilities we so often take for granted?

We don’t give them much thought until Mother Nature intervenes with a foot of snow or an ice storm. When the lights go out, the Internet stops streaming, water freezes in the pipes, and furnaces quit heating, we think about nothing but our precious utilities until they return.

The unsung heroes in these situations are the nation’s frontline utility workers that must brave the elements to do their jobs in the worst circumstances. We wait anxiously and depend upon their expertise and dedication to restore our lives back to normal.

One day soon, though, we could find that wait lasting longer and longer. Why? Our nation’s utilities are facing an unprecedented — and worsening — shortage of workers with the skills necessary to keep the grid functional.

In this article, we’ll take a closer look at the looming shortage of utility workers across the country. We’ll also examine how one training center in Kansas is addressing the issue. Finally, we’ll discuss easy-to-use training options that any utility can use to provide safe, hands-on skills training to their frontline workers.

The Power & Utilities Skills Gap

Industries of all kinds across the nation are facing a critical shortage of skilled workers, and the power and utility industries are no exception. Demand for workers in these industries remains strong, but finding new workers to replace the many workers ready to retire is proving to be a substantial challenge.

Industries of all kinds across the nation are facing a critical shortage of skilled workers, and the power and utility industries are no exception. Demand for workers in these industries remains strong, but finding new workers to replace the many workers ready to retire is proving to be a substantial challenge.

In an Energy Central article, author Karen Marcus notes:

“As older workers retire, many utilities are finding it difficult to replace them, and to attract employees with the skills needed to advance a 21st century industry. According to T&D World, Airswift and Energy Jobline found in a survey of over 17,000 professionals that ‘48 percent of power professionals are concerned about an impending talent emergency, with 32 percent believing the crisis to have already hit the sector and 38 percent reporting that their company had been affected by skills shortages.’”

The shortage of skilled workers is real, and experts predict it’s only going to get worse in the future. According to Marcus:

“The U.S. Department of Energy (DoE) Quadrennial Energy Review (QER) reports that, according to one study, the industry will ‘need 105,000 new workers in the smart grid and electric utility industry by 2030, but expects that only 25,000 existing industry personnel are interested in filling those positions.’ The remaining 80,000 employees in this supply-demand mismatch will need to be filled through recruiting and training. However, the industry is not expected to meet the forecasted need with its current recruitment and training rates.”

Obviously, something needs to change. As the DoE QER states, “Industry hiring managers often report that lack of candidate training, experience, or technical skills are major reasons why replacement personnel can be challenging to find.”

If the power and utilities skills gap is to be bridged, utility companies must find a way to effectively provide safe, hands-on training to equip current and future workers with the critical skills they need to fill frontline positions as quickly as possible. Fortunately, solutions are available, and in the next section we’ll examine an exemplary approach taken by an association of municipal utilities in Kansas.

A Training Pioneer

Nearly two decades ago, Kansas Municipal Utilities (KMU), an association of more than 100 public utilities across the state of Kansas, recognized a dire need to effectively train the next generation of field workers. The groundbreaking solution KMU pioneered was finally brought to life a few years ago in the form of a $3.2 million training center.

Nearly two decades ago, Kansas Municipal Utilities (KMU), an association of more than 100 public utilities across the state of Kansas, recognized a dire need to effectively train the next generation of field workers. The groundbreaking solution KMU pioneered was finally brought to life a few years ago in the form of a $3.2 million training center.

As author Rick Aguilar notes in a T&D World article, KMU’s 20,000-square-foot training facility was seen as “a way to short-circuit the learning curve so utilities could swiftly prepare new hires to work as effective front-line employees.”

KMU’s training center allows for safe year-round training. Not only does the facility feature dozens of wood poles, but it also boasts a variety of industrial-grade components to create the most realistic distribution system possible.

For utility workers, real-world, hands-on training is essential. As Aguilar notes in his article:

“Because safety is an integral part of all utility work, the new training center helps the students learn through hands-on instruction. While they can pick up on key knowledge through sitting in class and reading books, the real rubber meets the road when they are actively participating in hands-on learning.”

For example, KMU’s training center allows workers “to get hands-on training in a controlled environment…[that] mitigates some of the hazards inherent in utility work, and it allows the field workers to make mistakes in a safe environment.”

KMU has found that a combination of classroom work and hands-on training is the ideal training experience. “For example, if KMU offers a workshop on transformer theory and connections, then the linemen can get hands-on experience immediately after they receive classroom instruction to connect their learning to actual work.”

Training Solutions for Everyone

As Aguilar notes in his article, “[m]any of the members of KMU are small in scope, and as such, they don’t have the ability to provide a comprehensive training program or build a facility of their own.” That’s why the KMU training center is such an important and valuable resource for Kansas utilities.

As Aguilar notes in his article, “[m]any of the members of KMU are small in scope, and as such, they don’t have the ability to provide a comprehensive training program or build a facility of their own.” That’s why the KMU training center is such an important and valuable resource for Kansas utilities.

Nevertheless, “every utility needs to have a safe, qualified workforce.” So what are utilities in other states without the benefit of a KMU training facility supposed to do? Fortunately, there are a variety of training solutions that offer any utility the ability to provide critical hands-on skills training.

For example, DAC Worldwide manufactures a variety of unique training systems and industrial component cutaways that teach the essential hands-on skills frontline utility workers need most. In this final section, we’ll learn more about how utilities can use these systems to meet their training needs.

Transformer Wiring Training System (408-000)

DAC Worldwide’s Transformer Wiring Training System (408-000) is a realistic training device that replicates the conditions and circumstances that a utility worker encounters when making common power transformer connections in the field. This convenient tabletop training system provides hands-on training without the danger of full-voltage field experience.

DAC Worldwide’s Transformer Wiring Training System (408-000) is a realistic training device that replicates the conditions and circumstances that a utility worker encounters when making common power transformer connections in the field. This convenient tabletop training system provides hands-on training without the danger of full-voltage field experience.

For example, a 208VAC, three-phase source is stepped down, creating a 41VAC, three-phase system. The training system includes two complete sets of three-phase transformers so that paralleling can be explored. Users will also get first-hand experience using banana jacks, ground/primary connections, and secondary connections using both three-phase and single-phase applications.

Learners will study topics like analyzing transformer single-phase/three-phase voltages, identifying transformer turns ratio (TTR), and demonstrating how connections can produce incorrect motor rotation. They will also practice hands-on skills, such as performing transformer connections, interconnecting multiple transformers in Wye or Delta configurations, and simulating a burned-out transformer in a three-phase bank.

Transformer Connections Training System (491-000)

DAC Worldwide’s Transformer Connections Training System (491-000) teaches the key skills that a utility worker must master in order to confidently operate modern generating equipment, such as the paralleling of generators and connecting to a larger power grid. The system replicates the conditions and circumstances utility workers encounter when making common transformer connections in the field.

For example, learners can practice ground connections, primary connections, and secondary connections easily using banana jacks. Both three-phase and single-phase applications are provided, and a 208 VAC, 3-phase source is stepped down to a 41 VAC, 3-phase system for safety.

Users will find that the Transformer Connections Training System provides a safe and efficient, yet realistic alternative to a full-voltage field experience. Standard accessories include patch cords, fourteen (14) transformers, a panel-mounted voltmeter and phase rotation meter.

Industrial Transformer Cutaways

DAC Worldwide’s Single-Phase Transformer Cutaway (273-912) and Three-Phase Transformer Cutaway (273-915) are detailed, professionally-crafted transformer cutaways that depict a shell-type, single-phase transformer and a coaxially-wound, three-phase, delta-wye wired transformer, respectively.

DAC Worldwide’s Single-Phase Transformer Cutaway (273-912) and Three-Phase Transformer Cutaway (273-915) are detailed, professionally-crafted transformer cutaways that depict a shell-type, single-phase transformer and a coaxially-wound, three-phase, delta-wye wired transformer, respectively.

Through careful sectioning, the complete internal configurations of these transformers can be seen. Details shown include the laminated steel core, primary and secondary windings, and primary insulation.

Common transformer brands and models are chosen for sectioning for industrial relevance. Users will gain valuable insight into the inner workings of these transformers that they will encounter on a regular basis in the field.

- Published in News

New Marine Corps Doctrine Promotes Education & Training

Click here to view New Marine Corps Doctrine Promotes Education & Training as a multimedia presentation.

The few. The proud. Who are we talking about? The Marines, of course. That particular recruiting slogan has been permanently etched into our memories over the years.

And it’s a great slogan. The Marines are legendary for a training regimen that weeds out all but the strongest, creating a fighting force to be reckoned with. Indeed, the Marines have been on the front lines of every major U.S. military campaign of the modern era.

To be prepared for the future, however, the Marines know that training the same way they have in the past will not be sufficient. That’s why a recent doctrinal publication puts a new focus on education and continued learning.

Industry, always closely connected to the military, would do well to put a renewed emphasis on education and training, too. In this article, we’ll take a closer look at how partnering with a trusted technical training company like DAC Worldwide can prepare your students, workers, soldiers, and sailors for a bright future.

A New Doctrine for a New Era

According to a Marine Corps Times article, “the Marine Corps unveiled the Marine Corps Doctrinal Publication 7 [MCDP 7] in February [2019] as the service aims to promote education, training, and continued learning among Marines so they become students of their profession.”

According to a Marine Corps Times article, “the Marine Corps unveiled the Marine Corps Doctrinal Publication 7 [MCDP 7] in February [2019] as the service aims to promote education, training, and continued learning among Marines so they become students of their profession.”

How significant was this doctrinal development? MCDP 7 was the first new doctrinal publication issued by the Marines since 2001. Its goal: “to motivate Marines to personally assess where they can improve and understand the ‘why’ behind the significance of learning.”

Maj. Gen. William Mullen was quoted as saying “that he’s heard Marines say they joined the service to escape an academic education. But the Corps wants its personnel to understand that the two complement one another and that education prepares Marines to think quickly when faced with challenges.”

According to Mullen, “You need both training and education. Training prepares you for things you know you’re going to have to do…But the education piece comes in when the unknown starts to happen, which it always does.” Mullen specifically referred to the fact that the environments Marines face today present challenges that are only growing more complex.

This new doctrinal change comes as “Commandant of the Marine Corps Gen. David Berger is working to remake the Corps to better compete with potential high-end adversaries…Berger wants a leaner force to conduct sea denial operations, survive in a contested maritime environment and serve as a larger Naval expeditionary force.”

It’s Not Just the Marines

It’s Not Just the Marines

Speaking of the Navy, the Marine Corps Times article notes that the Navy announced in May 2019 “that it was modifying fitness reports to reflect an individual’s educational and training accomplishments, including military education courses, professional and academic certifications, among other things.”

Like the Marines’ new focus on education and continued learning, the Navy’s modified fitness reports are meant to “show that career-long military learning isn’t only job-related technical or tactical training, and that a commitment to higher education will produce Navy leaders with more refined critical thinking skills,” according to an article in the Navy Times.

Future Navy fitness reports will thus document educational performance, including “[m]ilitary educational courses, civilian institution coursework, and professional and academic certifications.” Navy leadership also indicated they will also encourage additional informal efforts, such as learning new technologies.

It’s All COOL

It’s All COOL

It’s no coincidence that the Marines and the Navy would emphasize professional and academic certifications. Much of the training that military personnel receive prepares them for future civilian jobs.

Obtaining professional and academic certifications while in the military can make it easier for personnel to transition to civilian life when their service is finished. All branches of the military recognize the importance of certifications in making that transition as easy as possible.

For example, the Marine Corps COOL site (Marine Corps Credentialing Opportunities On-Line) helps Marines see how their military training and experience matches up with civilian credential requirements. Such credentials could include important and valuable advanced manufacturing credentials from entities like the National Institute of Metalworking Skills (NIMS) and the Manufacturing Skill Standards Council (MSSC).

Marines using the COOL site can see whether military funding is available to help attain particular credentials. They can also see how the training and skills they’ve already acquired might match up with specific credentials valued by employers, such as NIMS’ Industrial Technology Maintenance (ITM) certification or MSSC’s Certified Production Technician (CPT) certification. There are also COOL sites for the Army, Coast Guard, Navy, and Air Force.

Industry Must Also Evolve

Industry Must Also Evolve

Given the military’s new focus on education and continued learning, it’s important that industries that work with and support the military evolve in a similar fashion. The military-industrial complex consists of all sorts of industries that work closely with the military to help them accomplish their mission.

These industries should take a cue from their military counterparts and begin to develop a similar focus on education and continued learning among their workforce. Industry workers will only be able to continue to keep pace with their military counterparts if they’re also seeking new educational opportunities and learning new skills and technologies.

Pushing an industrial workforce or a military organization toward more education and greater skill development can be a daunting task. That’s why it’s imperative that both the military and their industrial counterparts seek out and rely upon the expertise of a trusted technical training partner.

A Trusted Education & Training Partner

DAC Worldwide is a US-based world leader in technical training solutions. For over 35 years, DAC Worldwide has been helping industrial employers and military organizations with realistic, hands-on training systems.

DAC Worldwide offers a wide range of product solutions to fit all your training needs. From training systems that teach a full range of skills to cutaways that increase understanding of how a component works, we have what you need.

For example, many military personnel work in the same skilled occupations as civilians. This means they need a solid foundation in various technologies, including electrical, electronics, fluid power, and mechanical drives.

Whether you train military personnel working on military bases or civilian crews with military contracts, DAC Worldwide’s military training solutions offer an unmatched range of products to allow you to create the course you need or to fill in any gaps that you have in your current training.

Let’s take a closer look at four specific DAC Worldwide products that can take your training program to the next level:

Lock-Out/Tag-Out Training System (811-000)

DAC Worldwide’s Lock-Out/Tag-Out Training System features a realistic, simulated working process environment that facilitates introductory training with hands-on activities related to the process of identifying and locking out sources of dangerous potential energy in an industrial setting. The training system includes two process tanks; a centrifugal pump; a complex, multi-purpose piping network; electrical controls; a variety of lockable system components; and a lock-out/tag-out kit that features a large number of commonly-encountered locking and tagging devices.

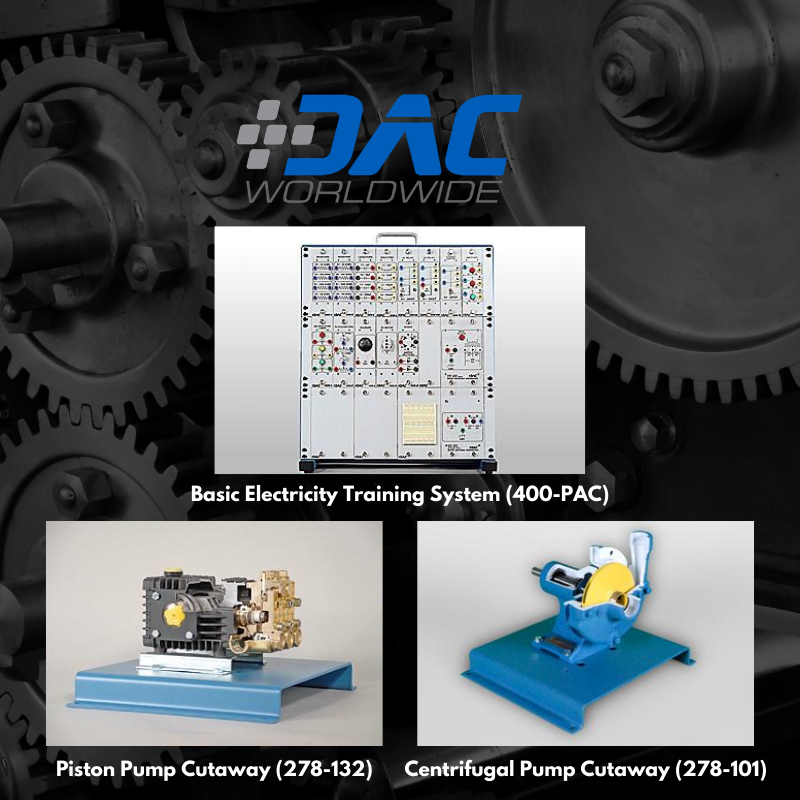

Basic Electricity Training System (400-PAC)

Basic Electricity Training System (400-PAC)

DAC Worldwide’s Basic Electricity Training System teaches basic AC and DC electrical principles. Learners will explore how electricity is used for power and control in various sectors. The trainer covers industry-relevant skills, such as installing, operating, and troubleshooting AC and DC electrical circuits in a variety of applications.

Piston Pump Cutaway (278-132)

DAC Worldwide’s Piston Pump Cutaway is an industrial piston pump that has been carefully sectioned and color-coded to train learners in the design, operation, construction, and maintenance of this common process pump used throughout industry. The cutaway exposes and showcases the complete internal configuration of an industrial piston pump. Moreover, seal features and bearings have been retained to allow realistic, hands-on pump maintenance and operation training.

Centrifugal Pump Cutaway (278-101)

DAC Worldwide’s Centrifugal Pump Cutaway is a sectioned centrifugal pump that provides realistic training in the operating principles, construction details, and maintenance of common centrifugal process pumps used throughout industry and the military. It includes various sectioned components, such as seals and bearings, as well as showcasing the pump’s impeller.

Contact DAC Worldwide Today

Is your organization ready to take its industrial technical training to the next level? Contact a DAC Worldwide expert today for a personal consultation regarding your training needs and how our variety of training systems, cutaways, dissectibles, and models can prepare both industrial workers and military personnel for the future challenges they face.

- Published in News