DAC Worldwide Offers Hands-On Electrical Generation Fundamentals Training

Industrial facilities know how important electrical skills are to ensuring that things run smoothly and safely. What many people don’t know, however, is how diverse electrical skills can be. While basic electrical skills, such as wiring a circuit or troubleshooting a transformer, are extremely valuable and quite common, some facilities require specialized advanced electrical skills, such as those relating to power generation and managing multiple power plants on an electrical grid.

For example, one industry that’s currently booming will likely lead to a need for workers with advanced electrical skills related to power generation. Which industry are we talking about? Semiconductor manufacturing!

According to a recent article in The Register, author Tobias Mann notes that “AMD president Victor Peng addressed [at the recent Hot Chips Conference] one of the biggest challenges facing the semiconductor industry as it grapples with growing demand for ever larger AI models: power.”

How big is the challenge facing the semiconductor manufacturing industry? Mann points out that “AI’s seemingly insatiable thirst for power has gained considerable attention over the past year – so much so that some operators have begun setting up shop next to nuclear power plants. And the problem isn’t going to get easier.”

According to Mann, Peng has expressed worry about “finding enough power sources and being concerned about the grids and the distribution.” In fact, Mann notes that Peng has “noted that these [AI] models have very quickly gone from requiring hundreds of megawatt hours to train to hundreds of gigawatt hours.”

How do you address such a large-scale challenge? “Peng argues that the semiconductor industry needs to focus more attention on making the infrastructure not only more performant, but more efficient.” Indeed, the burgeoning semiconductor manufacturing industry must bring together all the players necessary to craft large-scale infrastructure solutions that ensure that the electrical grids of tomorrow will be able to support the demands of new technologies.

Addressing fundamental electrical generation challenges will require highly skilled workers who possess advanced electrical skills related to power generation. Hands-on training in electrical generation fundamentals can elevate workers’ skills to the next level.

For example, DAC Worldwide’s Electrical Generation Fundamentals Training System (490-000) represents a true simulator depicting multiple power plants on a grid. The unit basically acts as the control center for a generating station and simulates four separate generating units. The system demonstrates the principles of generator operation and represents the relationships that an operator must master in order to confidently operate generators.

Practice in paralleling machines of various sizes is easily accomplished without tying up the plant simulator. The synchroscope display includes a phase angle display, representing the phase difference between running and incoming.

A graphic representation of how load is shared, by two machines of various sizes, is shown by a house curve. The relationship between real load and reactive load is displayed by meters and by a pictorial diagram of the power triangle on the graphic display. Inductive, resistive, and capacitive loads can be turned on and off reinforcing the effects of reactive load and demonstrating how power factor can be changed.

Users will study topics, such as AC generators, reactive power control, loss of load, and trainer operation. They will also practice hands-on skills, such as correctly performing paralleling operation, generator responses to inductive/resistive/capacitive loads, calculating power factor, and observing a diesel generator autostart and load. The Electrical Generation Fundamentals Training System is only one of DAC Worldwide’s many electrical training systems. Visit DAC Worldwide online to learn more about its many other electrical training systems!

- Published in News

Staying Protected: Hands-On Transformer Training in Safe, Controlled Environment

To view a multimedia presentation of “Staying Protected: Hands-On Transformer Training in Safe, Controlled Environment”, please click here.

The life of a power line worker can be a precarious one. From maintaining interstate power grids to servicing transmission lines and towers, line workers are often tasked with jobs that aren’t for the faint of heart.

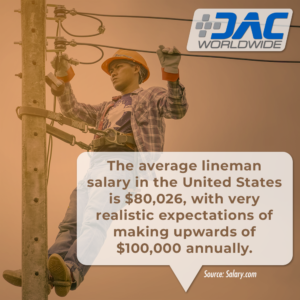

The profession is considered one of the most dangerous in America, with 35 fatalities in 2019 around the United States. The compensation for such an intimidating trade, though, is notable.

According to salary.com, the average lineman salary in the United States is $80,026, as of February 2021. The career offers very realistic expectations of making upwards of $100,000 annually before turning 25 for younger students.

Today, the career is becoming safer, thanks to developing safety technologies. There are Linemen Training Schools all over the United States and Canada, with many finding interest in the unique field of high-voltage electrical technology.

Despite the demands, it is critical for workers to be properly trained on the power that electricity holds, both physically and metaphorically. Due to its hazardous nature, becoming a lineman requires extensive technical knowledge and safety skills to help ensure worker safety.

In the past, teaching the ins and outs of transformers was primarily paper-based, with some programs even opting for full-voltage training. Most of the time, the “real” learning was done on-the-job.

But things have changed in the electrical technology field. Training future lineworkers no longer requires a book-only approach, or the dangers that come with full voltages. DAC Worldwide’s Transformer Connections Training System (413-000) is a utility worker training aid that provides learners with real-world, hands-on practice working with transformers.

What is the Transformer Connections Training System?

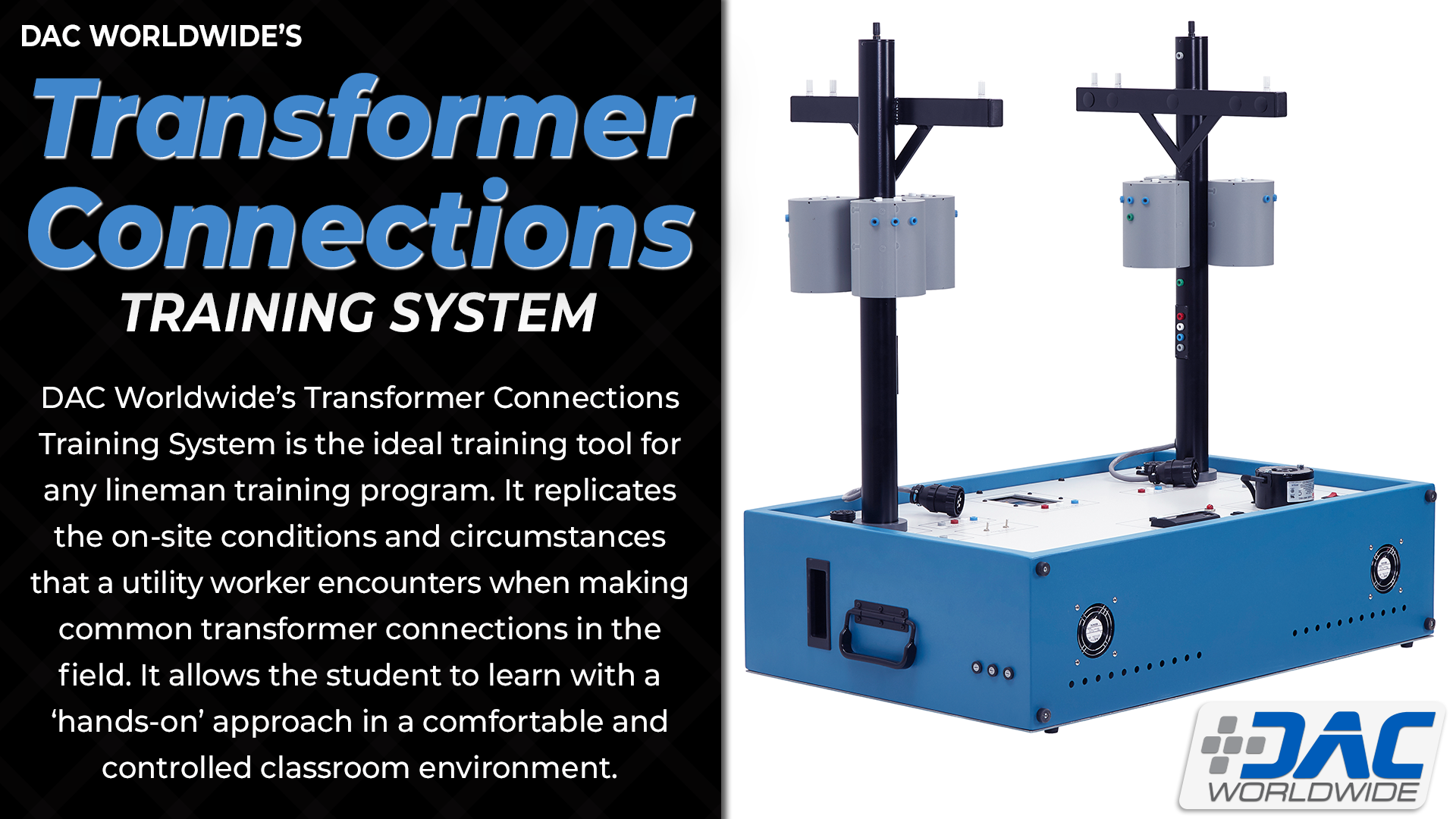

DAC Worldwide’s Transformer Connections Training System is the ideal training tool for any lineman training program. It replicates the on-site conditions and circumstances that a utility worker encounters when making common transformer connections in the field. It allows the student to learn with a “hands-on” approach in a comfortable and controlled classroom environment.

Gone are the days of full-voltage training and paper-based learning, as the training unit is internally fused and includes a recalibrated reduced-voltage meter to make training safe, efficient, and realistic. As students train on the system at 4100 VAC, for example, they will only be operating at 41 Volts. This allows them to see real line voltage without the potential of getting hurt.

Put together in a welded steel cabinet, the Transformer Connections Training System is wired for both single-phase and three-phase activities. It includes 14 transformer cans, which are wired with different configurations to allow for a variety of set-ups, as well as a panel-mounted voltmeter and a phase rotation meter. It requires a 208 VAC / 3-phase / 60Hz / 4-wire connection.

In addition to the hands-on approach, the Transformer Connections Training System includes a Student Training Manual with a variety of topics, like performing single-phase transformer connections, identifying 3-phase connections, and demonstrating how capacitors affect line voltage and current. Learners will also learn how to demonstrate parallel single-phase and 3-phase transformers, and other transformer-related topics and skills.

Other Transformer Training Products

In addition to the Transformer Connections Training System, DAC Worldwide also offers slightly different variation called the Transformer Wiring Training System (408-000). This training tool is ideal for future industrial electrical programs and electricians, as it covers a basic course on transformers. It can also be used in residential electrical programs, as the system also shows how to connect a residential service.

Like the 418-000, the Transformer Wiring trainer takes the safe approach in learning by using low-voltage outputs while simultaneously simulating high-voltages. It replicates the single-phase transformer connections, as well as both delta-wye 3-phase transformer connections. All of the transformers are the same, and build into the unit, with the middle representing six different generators.

Students will be able to demonstrate proper installation of ground connections, primary and secondary side connections, and parallel transformer connections. The system also includes eight built-in instructor fault switches, which simulate failure conditions and allow real-time assessment and troubleshooting for students.

In addition to training systems, DAC Worldwide also offers two Transformers cutaways: one depicting a single-phase transformer, with the other showcasing a three-phase. Cutaways are real-world industrial components that have been restored, cut away, and refinished using durable urethane coatings. Each of these industrial components has been professionally sectioned to expose each device’s primary components, with functionality completely retained.

The Single-Phase Transformer (273-912) highlights a common shell-type, single-phase transformer found in manufacturing facilities and refineries, among others. The Three-Phase Transformer Cutaway (273-915) features a common coaxially-wound, three-phase, delta-wye transformer found in various industrial and commercial applications.

How Can DAC Worldwide Help Your Training Program?

With more than four decades of experience in industrial training, DAC Worldwide’s reach extends far beyond just electrical products. In fact, DAC Worldwide possesses knowledge and expertise in a wide range of technical topics, including Electronics, Fluid Power, Heat Transfer & Steam, HVAC, Machining & Measurement, Mechanical Drives, Oil Production, Process Control & Instrumentation, and Pumps, Compressors & Valves.

Our training aids range from training systems and sample boards, to models and dissectibles – with real-world, hands-on learning being the core of each product. For more information on how DAC Worldwide can enhance your industrial training program and provide you with the best training solutions available, please click here.

- Published in News