Sustained Demand Boosts Manufacturing Equipment Orders

As consumers, it’s easy to see the effects of a prolonged battle with inflation. It seems like everywhere you go, it costs more these days for the things you need. From grocery stores and restaurants to gasoline and utilities, the consumer dollar just doesn’t stretch as far as it used to.

Are manufacturers experiencing something similar? If you watch the news, it’s pretty much been doom and gloom for some time now, even though many key economic indicators reflect a recovering economy that’s more robust than it’s been since the COVID-19 pandemic.

While it’s true that inflation and high interest rates can affect businesses just like they do consumers, there’s evidence that manufacturers see the light at the end of the tunnel. In fact, it appears that many manufacturers are ready to resume capital investment in the form of new manufacturing equipment orders.

A recent American Machinist article notes that “[a]n uptick in demand from machine shops and OEMs may indicate manufacturers are overlooking the high interest rates that have restrained new orders through the year to-date, recognizing sustained consumer and business demand for finished products.”

The article reports that “U.S. machine shops and other manufacturers increased their demand for capital equipment during May, with new metal-cutting and metal-forming and fabricating machines rising 21.8% from April to $386.7 million for the month. That represents a 6.5% increase in new orders from May 2023.”

“These figures are supplied by AMT – the [Association] for Manufacturing Technology in its U.S. Manufacturing Technology Orders report, a monthly review of new orders for machine tools (i.e., ‘manufacturing technology’), that serves as an indicator of future manufacturing activity because it quantifies machining operations’ investments in preparation for new production programs.”

In its report, AMT notes that these developments represent “a realization by manufacturers that capital investment is necessary ‘to meet the sustained demand for goods and machinery from consumers and businesses,’ in spite of the ongoing strain of high interest rates that have weighed against new-order activity since January.”

AMT also observed that “[d]emand for manufacturing technology among OEM is notably strong among electrical equipment manufacturers and power-generation and transmission equipment manufacturers. ‘These industries undoubtedly benefit from the government investment authorized by the CHIPS and Infrastructure acts and are therefore less sensitive to interest rates than others.’”

This is good news for electrical power generation and transmission equipment manufacturers. New equipment often means increased capacity, which in turn means new employees. Ensuring that new employees – and current employees – have the hands-on skills they need to succeed in the workplace remains a top priority.

How do companies and schools train the next generation of professionals with the electrical skills they need to succeed in the modern workplace? A thorough review of training systems is a great place to start. Do employees and students have access to hands-on training with actual components they’ll encounter on the job?

If not, partnering with established companies to provide industrial-quality training systems that will stand the test of time will help ensure a competent workforce. Be sure to check out DAC Worldwide’s variety of hands-on electrical training systems that feature the real-world components workers will encounter in the field!

- Published in News

Electrical Safety is no Joke

Did you hear the latest parental advice on how to keep kids from chewing on electrical cords? You ground them until they conduct themselves properly!

OK, we may have started this article with a (terrible, absolutely awful) joke, but we did so to make a point: electrical safety is no joke, especially in the workplace. In fact, bad dad jokes are the only time electrical safety is a laughing matter.

That’s a lesson that a plastic and resin manufacturer with facilities in Georgia and Alabama learned the hard way recently. According to a recent Plant Services article by Alexis Gajewski, “[a]n [Occupational Safety and Health Administration] OSHA investigation has determined that Crown USA Inc. could have prevented the death of a 37-year-old maintenance technician…if they were following required safety rules designed to keep machines from starting up during maintenance.”

Gajewski notes that “[t]he worker was inside an unlocked hooding palletizer, servicing the machine, when they suffered fatal crushing injuries.” OSHA Area Director Jeffery Stawowy said, “Employers must understand federal workplace safety regulations exist to help prevent tragedies like the one that occurred at Crown USA Inc.”

The resulting OSHA investigation revealed “eight serious and six other-than-serious violations. These violations include failing to implement adequate machine guarding, a lack of training on energy control procedures, exposing workers to serious respiratory hazards, and failing to provide proper personal protective equipment (PPE).”

Not only did a maintenance worker needlessly lose their life, but the company also “faces $98,699 in penalties.” Other companies would be wise to learn from Crown USA Inc.’s shortcomings and institute rigorous safety training, including adequate training on energy control procedures.

Manufacturers can always benefit from a regular audit of safety training. The best way to improve a workplace’s safety culture and teach workers to prioritize safety is to implement a quality safety program that teachers workers the knowledge and skills they need to stay safe in the workplace.

As previously mentioned, one of the most basic—and important—areas to focus on is the control of hazardous energy, often known by its more popular moniker “lock-out/tag-out or LOTO.” According to OSHA, “[e]nergy sources including electrical, mechanical, hydraulic, pneumatic, chemical, thermal, or other sources in machines and equipment can be hazardous to workers. During the servicing and maintenance of machines and equipment, the unexpected startup or release of stored energy can result in serious injury or death to workers.”

That’s exactly the lesson that Crown USA Inc. learned too late. Fortunately, “[p]roper lock-out/tag-out practices and procedures safeguard workers from hazardous energy releases.” Teaching workers hands-on LOTO skills will help them to understand how to properly control hazardous energy and maintain a safe work environment.

For companies looking to improve their safety training, partnering with established companies to provide industrial-quality training systems that will stand the test of time will help ensure the continued safety of the workforce.

For example, DAC Worldwide offers a safety training system specifically designed to give employees the hands-on experience they need to master lock-out/tag-out skills. Be sure to check out DAC Worldwide’s Lock-Out/Tag-Out Training System and contact a DAC Worldwide representative to learn how you can improve your training today!

- Published in News

Will Oil and Gas Workers Get Left Behind?

When you think of oil production, which countries come to mind? If you’re like many people, you may be thinking of countries throughout the Middle East, such as Saudi Arabi, Qatar, and United Arab Emirates. Would you believe, though, that one of the preeminent oil basins in the entire world is located right here in the United States?

In a recent Forbes article by Ian Palmer, the author notes that the Permian basin, which is located in southeast New Mexico and west Texas, “is the king of crude in the U.S.” Responsible for “producing over 6 MMbpd (million barrels per day),” the Permian has made New Mexico “the second highest oil-producing state in the U.S.”

Experts estimate “that crude oil from the Permian will increase 8% this year…leading to record levels of oil production in the U.S. that will approach 14 MMbpd by 2025…the highest oil production in the world.” However, Palmer points out that the oil and gas industry “predicts peak oil production in the 2030s.” After that peak, “[t]he general idea is that fossil energies would decline as renewable energies would increase.”

What’s driving these changes? (Pun totally intended.) If you guessed electric vehicles (EV), you’d be partially right. In addition to EVs, the push for renewable energy sources also comes from efforts to address climate change, as well as the fact that fossil fuel supplies are not renewable and will one day have to be replaced with alternatives.

Oil giant British Petroleum estimates “worldwide fossil energy consumption falling steadily from 80% now to 28-55% by 2050. Coal will fall the most, oil will fall, and natural gas may or may not fall.” New Environmental Protection Agency rules aimed at vehicle emissions could spur the transition to EVs, though, which could accelerate the decline in oil production.

This might seem like a problem for a state like New Mexico, but Governor Lujan Grisham has made a “strong commitment to address climate change. The state has mandated 80% of electricity to be provided by renewables by 2040, and greenhouse gas (GHG) emissions to be reduced by 45-50% based on 2005 levels.”

As the transition to renewables gains momentum, many in New Mexico are beginning to ask questions about what is to become of the state’s oil and gas workers. According to a recent article from The Wilderness Society, author Nicole Segnini notes that “the oil and gas industry hugely depends on Latinx and immigrant workers. According to New Mexico’s Bureau of Labor Statistics, Latinos represent 46% of the state’s oil and gas workforce, many of whom are immigrants.”

Segnini acknowledges that “New Mexico, and the U.S. as a whole, must transition to renewable energy. But as they make that change, they need to ensure these workers, who have played such a crucial role in the economy, are not left behind. The state must value their expertise and livelihoods as it navigates the necessary transition to a healthier, more sustainable economy.”

For many Latinos and immigrants in New Mexico, “jobs in or supporting the fossil fuel industry are among the very few available to care for their families.” Unfortunately, it’s also this same group “who bears the brunt of the industry’s challenges and pollution.”

Segnini notes that “[o]il and gas workers in Southeast New Mexico…are not sure if they’ll be replaced, if they’ll have to move or if they’ll even get a fair chance at new clean energy jobs.” In fact, “[m]any fear people from outside the state of New Mexico will get those jobs instead, leaving them without a paycheck—and without easy access to training that could help them transition into safe and quality jobs in renewable energy or other industries.”

For example, Gabriela Rueda, originally from Mexico and living in New Mexico for the last five years, says, “Our community needs funds to improve the workforce, have other developments and training with work equipment.” She and others working in the New Mexico oil and gas industry “all have one thing in common: they understand that the oil and gas industry has many flaws and could end. They just want to be considered when that happens.”

Thanks to the advocacy of Somos Un Pueblo Unido, a New Mexico immigrant and worker rights organization, the most recent New Mexico state legislative session secured “$6 million from the state’s budget for New Mexico’s adult education division to expand integrated education and skills building programs for disengaged and difficult to reach adult workers,” as well as “a $1 million pilot program to provide cash stipends to low-income workers enrolled in adult education and integrated education training program.”

Segnini concludes that “it is crucial the state…provides equitable access to workforce development and adult education programs and invests significantly in supplemental income for workers enrolled in training…Providing support, retraining opportunities and pathways to new employment sectors ensures that these workers are not left behind but rather empowered to thrive in a rapidly evolving energy landscape.”

For New Mexico and any other states navigating the transition from fossil fuels to alternative energy sources, the Amatrol family of companies can help with all your training needs. Oil and gas companies will continue to need skilled workers as oil production continues to increase over the coming decade.

As the renewable energy transition ramps up, companies will still need skilled workers. Many of the skills workers will need will be like those needed to produce traditional fossil fuels, while new skills will also need to be mastered. Amatrol, along with its sister companies, DAC Worldwide and Bayport Technical, offer a wide variety of training tools and systems to teach workers the skills they need to succeed.

For example, both DAC Worldwide and Bayport Technical manufacture oil and gas training tools and systems that teach hands-on technical skills with real industrial equipment they’ll encounter on the job. Here are a couple of samples of the types of training aids these companies produce:

- DAC Worldwide’s Extended Wellhead Assembly Cutaway (295-795E) depicts the complete assembly of components used in creating a wellhead, which are used in oil & gas production operations. The full-size, fully detailed example of a high-pressure wellhead assembly gives learners a first-hand view into a component that is found in oilfield applications worldwide.

- Bayport Technical’s Cooling Tower Working Demonstrator (142-CT2) is a scaled, acrylic replica of a forced draft cooling tower used in oil refineries and petrochemical plants. This working demonstrator allows a full view of how water is filtered through the tower to cool it off and then return it the factory. This tabletop system includes a water basin and distribution system, heater assembly, pump, fan, splash bars, air intake louvers, draft eliminators, and temperature gauges.

When it comes to teaching the skills workers need in the alternative energy sector, Amatrol provides a full array (again, pun totally intended) of solar and wind trainers. Here are a couple of examples of Amatrol’s green technology training systems:

- Amatrol’s Solar PV Troubleshooting Learning System (950-SPT1) teaches a range of solar photovoltaic (PV) operation, maintenance, and troubleshooting skills through a unique combination of eLearning curriculum and hands-on experience with real industrial solar PV components. That’s why Amatrol’s Solar PV Troubleshooting Learning System features a wide variety of industry-standard solar PV equipment to teach relevant hands-on skills, including: a mobile workstation with a combiner box, MPPT charge controller, micro inverter, grid interactive inverter, programmer, and communications gateway and hub.

- Amatrol’s Turbine Electric Hub Troubleshooting Learning System (950-TEH1) teaches learners adaptive skills for wind turbine operation, adjustment, and troubleshooting in a wide variety of situations. Turbine Electric Hub Troubleshooting training system allows learners to develop and practice component, subsystem, and system level skills. It is fully functional like a utility-scale turbine electric hub. Turbine Electric Hub Troubleshooting includes Amatrol’s unique electronic fault insertion system, which allows instructors to electronically create realistic hub problems and then track the learner’s progress in solving the problem.

Reach out to an expert training consultant with Amatrol today to get started on the path to training the next generation of workers!

- Published in News

Resurgence of Manufacturing Spotlights Need for Training

It’s no secret that the COVID-19 pandemic took a toll on manufacturing in America. Alongside nearly every other industry, manufacturing faced major challenges in 2020 and the years that followed, particularly with regard to supply chain problems.

Fortunately, the tide appears to be turning. In a recent Bloomberg article, authors Enda Curran and Katia Dmitrieva report that “[a]ssembly lines around the world are starting to hum again, marking a turn in a years-long manufacturing slump.” That’s good news here and abroad.

According to Curran and Dmitrieva, “[t]he nascent industrial recovery is led by the world’s two biggest economies. Chinese manufacturing has made a strong start to the year, boosting the economic outlook, and US factory activity unexpectedly expanded last month for the first time since September 2022, buoyed by rising new orders and a jump in production.”

Factory activity isn’t the only key indicator reflecting an uptick in American Manufacturing. The authors note that “JPMorgan/S&P Global’s manufacturing index notched a second month above expansionary territory in March and sits at the highest level since July 2022. If sustained, that’ll help catalyze a broader and stronger economic recovery that’s already spreading beyond the US.”

The recovery could be a bumpy ride. However, the authors believe there is reason for optimism: “While it’s still early days…the activity nonetheless marks a departure from the slowdown that took hold globally as consumer demand pivoted to spending more on services such as travel and dining out instead of buying more goods as pandemic-era restrictions ended.”

As American manufacturing ramps up during this period of recovery, manufacturers will still be faced with a labor pool that continues to have fewer highly skilled workers than employers need. Where will the workers come from? Until educational institutions expand the pipeline of skilled workers, manufacturers will have to pick up some of the slack of training workers with the skills they need to succeed.

Of course, not every manufacturer is prepared to train workers with the knowledge and hands-on skills they need to make an immediate impact in the workplace. Fortunately, employers don’t have to be training experts to launch an effective training program.

The experts at DAC Worldwide can help any manufacturer quickly and efficiently implement a training program that targets the specific skills workers need to be productive. For example, a thorough review of training systems is a great place to start. Do employees have access to hands-on training with actual components they’ll encounter on the job?

If not, partnering with established companies to provide industrial-quality training systems that will stand the test of time will help ensure a competent workforce. Be sure to check out DAC Worldwide’s variety of hands-on focused skills training systems that feature the real-world components workers will encounter in the field!

- Published in News

Foundational Electrical Skills Remain Essential in the Modern Industrial Workplace

Do you remember the good old days of the COVID-19 pandemic? Me neither. Empty store shelves devoid of your favorite products. Supply chain disruptions affecting every aspect of your modern life. No, those were not fun times.

Anyone shopping for a new or used vehicle during the pandemic probably remembers the lack of vehicle supply leading to huge price increases. In some cases, thousands of new vehicles sat in parking lots waiting for one tiny, but critical component—usually a semiconductor or “computer chip”—before they could be shipped to dealers for sale.

The fact that our auto industry relied almost exclusively on foreign suppliers for such key components did not go unnoticed by the federal government. In a recent IndustryWeek article, author Sarah Shinton notes that “[i]n 2022, the White House signed the CHIPS and Science Act into law, a bipartisan effort to increase domestic advanced semiconductor manufacturing. The legislation made a historic $52 billion investment in American semiconductor research, manufacturing and workforce development.”

Is your area one of those lucky enough to have acquired a new semiconductor manufacturing facility? If so, you may not have heard a lot about it yet. Shinton points out that “new projects are facing construction delays and permitting issues.”

More problematic, however, is the fact that there’s a larger issue looming: “the country might be unable to generate enough electricity to power new fabrication plants, leaving billions of dollars in federal funds stranded and one of its most critical supply chains vulnerable.”

Shinton notes that “[w]hile manufacturing semiconductors has always been energy-intensive, the process is becoming even more so as chips are developed to be smaller and more powerful. The most advanced semiconductors require extreme ultraviolet (EUV) lithography machines, which use ultraviolet light produced by rapid-fired lasers to burn fine details on silicon wafers.”

Unfortunately, “these machines consume 10 times as much power as earlier generations of equipment.” How much power is that? A lot. Shinton points out that “the Taiwan Semiconductor Manufacturing Company (TSMC), the world’s leading semiconductor manufacturer,…now consumes more electricity than some U.S. states.”

This presents a huge problem for future chip fabrication plants in the U.S. According to Shinton, “semiconductor manufacturing creates large pockets of demand in the areas where fabrication plants are located. A rapid increase in load presents challenges for grid operators who maintain the delicate balance between electricity supply and demand, preventing curtailments or worse, blackouts.”

The phasing out of coal-fired power plants in favor of alternative sources, such as natural gas, solar, and wind, could also be problematic. “The vast amount of electricity needed to onshore this new manufacturing comes at a time when America’s power grid is increasingly unreliable as the country undergoes rapid changes…many regulators are raising alarms that power plants are being retired faster than they are replaced, leaving the country at risk of electricity shortages.”

Moreover, “[t]hese mass retirements are also happening while electricity demand nationwide is increasing from data center growth, expansions in manufacturing and intensifying weather conditions…Over the past year, the five-year load growth forecast nearly doubled, jumping from 2.6% to 4.7%…Without expanding the high-capacity transmission system, our grid will struggle to meet this demand.”

What do these problems mean for the future workforce? Not only will dozens of semiconductor manufacturing facilities need highly skilled workers for their plants, but the industries supporting these new ventures will need thousands of workers with fundamental electrical skills as public utilities work together with industry to ensure a stable electrical grid for the future.

How do companies and schools train the next generation of professionals with the electrical skills they need to succeed in the modern workplace? A thorough review of training systems is a great place to start. Do employees and students have access to hands-on training with actual components they’ll encounter on the job?

If not, partnering with established companies to provide industrial-quality training systems that will stand the test of time will help ensure a competent workforce. Be sure to check out DAC Worldwide’s variety of hands-on electrical training systems that feature the real-world components workers will encounter in the field!

- Published in News

Electrical Safety Training Sets the Stage for a Secure Workplace

My neighbor asked me to install a new electrical outlet in his master bathroom. He was eventually shocked to learn that I’m not a licensed electrician! OK, that’s an old—and terrible—joke, but it does underscore the importance of safety when it comes to working with electrical current.

In the modern industrial workplace, there are a whole host of skills that workers need to know. No matter how highly skilled a worker might be, however, nothing will matter if the fundamental basics of safety aren’t mastered.

When it comes to safety, one of the most important skills that workers must learn is how to work safely with electricity. According to a FacilitiesNet article by Ashley Beebe, “[w]hen working with electrical distribution systems and components, frontline maintenance technicians and engineers often face the potential for serious injury or death from electrocution or arc flashes, but knowledge of safety tips, procedures, codes and regulations can help technicians and engineers lessen the risk and potential for serious injury or death.”

That’s why, “[a]ccording to the Occupational Safety and Health Administration (OSHA), employees must not work near an electric current, any equipment, or a part they may come in contact with while on the job, unless it has been de-energized. If an electric current has not been de-energized, employees must be protected by isolation, insulation, warning signs or other methods.”

In safety training, the control of hazardous energy is often known by its more popular moniker “lock-out/tag-out or LOTO.” According to OSHA, “[p]roper lock-out/tag-out practices and procedures safeguard workers from hazardous energy releases.” Teaching workers hands-on LOTO skills will help them to understand how to properly control hazardous energy and maintain a safe work environment.

For companies looking to improve their safety training, a thorough review of current training materials is a great place to start. Do employees have access to hands-on training with actual components they’ll encounter on the job? If not, partnering with established companies to provide industrial-quality training systems that will stand the test of time will help ensure the continued safety of the workforce.

For example, DAC Worldwide offers a safety training system specifically designed to give employees the hands-on experience they need to master lock-out/tag-out skills. Be sure to check out DAC Worldwide’s Lock-Out/Tag-Out Training System and contact a DAC Worldwide representative to learn how you can improve your training today!

- Published in News

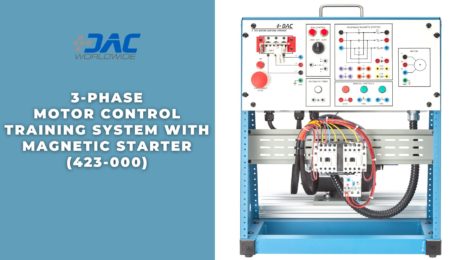

Learn Essential Motor Control Skills with DAC Worldwide’s Hands-On Training Systems

Industrial machinery requires a wide variety of different types of motors to function efficiently and effectively. Whether they’re powering a compressor, pump, fan, or conveyor, three-phase induction motors keep operations at industrial facilities moving steadily.

Many induction motors require significant power given their heavy-duty applications. Moreover, they draw a high electrical current upon start-up. In fact, start-up current can sometimes be as much as 5-6 times what they draw at normal operating speed. This is why they require a special device called a motor starter.

If industrial motors relied solely on circuit breakers or fuses, those would trip or blow every time the motor started. That’s obviously unacceptable in an industrial setting. Instead, specialty motor starters start and stop induction motors using manual or automatic switches. They also protect motor circuits from excessive heat caused by overloads during normal operations.

Motor starters consist of two primary parts: (1) an electromagnetically operated set of contacts (called a contactor) starts and stops the motor by beginning or ending the flow of electrical current; and (2) an overload relay that protects the motor from drawing too much current and overheating.

Likewise, motor starters usually consist of two circuits: (1) a power circuit that transmits the primary voltage to the motor via the starter contacts and overload relay; and (2) a control circuit that manages the contactor coil that creates the electromagnetic field that operates the power contacts.

Because there are so many different types of industrial applications that require induction motors, there are likewise a wide variety of different types of motor starters. One common type is the reversing magnetic motor starter. Reversing starters, as their name implies, are specifically designed to efficiently reverse shaft rotation of a three-phase induction motor.

Reversing starters work by interchanging two contactors supplying electrical current to the motor, as well as having both a forward and a reverse starter. To ensure that only one of the starters can be engaged at any particular time, reversing starters feature both mechanical and electrical interlocks for enhanced safety.

Industrial maintenance technicians must be familiar with all sorts of induction motors and their motor starters. Hands-on training in electrical maintenance can elevate your technicians’ skills to the next level.

For example, if you want to ensure your maintenance technicians have the skills to work with reversing magnetic motor starters, DAC Worldwide’s 3-Phase Motor Control Training System with Magnetic Starter (423-000) offers comprehensive training in the operational principles, wiring, fault troubleshooting, and application of industrial three-phase, reversing magnetic motor starters.

The 3-Phase Motor Control Training System with Magnetic Starter is self-contained, allowing for individual study by a single student or a small student group. While often used independently, the training aid can be integrated with other optional products relating to programmable controllers, pilot devices, and motor-driven mechanical systems.

This electrical trainer includes a variety of industry-standard components, including: a three-phase induction motor; reversing magnetic motor starter with auxiliary contacts, mechanical and electrical interlocks, and overload relay; on-board wiring devices including Hand-Off-Auto (HOA) control station, manual control station, and automatic timer; color-coded, shielded banana-jack receptacles for all motor leads, supply connections, and control components; circuit breaker with lock-out/tag-out; keyed power switch; pilot light and emergency stop switch; and four instructor fault switches to create common component faults for troubleshooting instruction.

The 3-Phase Motor Control Training System with Magnetic Starter is only one of DAC Worldwide’s many electrical training systems. Visit DAC Worldwide online to learn more about other electrical training systems, such as the Three-Phase, Squirrel Cage Rotor, AC Motor Training System; 1-Phase Motor Control Training System with Manual Starter; DC Permanent Magnet Motor Control Training System; and many more!

- Published in News

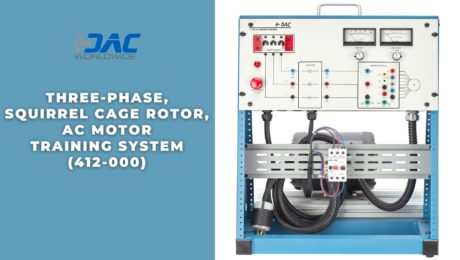

DAC Worldwide Offers AC Motor Training in a Compact, Convenient System

Today’s industrial facilities feature a wide array of different types of machines, from simple pumps to complex automated robots. One of the most common machines you’ll find in any industrial setting is the electric motor.

Simple, versatile, and available in many different configurations, electric motors carry the burden of converting electrical energy into mechanical energy. At the most basic level, electric motors can be distinguished based upon their power source: direct current (DC) or alternating current (AC).

For industrial use, the most common type of electric motor is the AC induction motor (also known as an asynchronous motor). The name “induction” is used because electrical current is induced in the rotor rather than supplied externally. The popularity of the AC induction motor stems from its simplicity, relatively low cost, and excellent reliability in a wide range of applications.

Induction motors can be further divided into two primary types: single-phase and three-phase, depending upon the type of electricity used to power them. The most-used electric motor throughout industry is arguably the three-phase squirrel cage induction motor.

Squirrel cage motors rely upon electromagnetic induction to create motion by converting electrical current into rotational energy. AC current travels through the stator, the stationary portion of the motor that consists of the housing and a series of windings (usually copper). The three-phase AC power energizes the windings, creating a rotating electromagnetic field.

The rotating part of the motor, known as the rotor, sits inside the stator. It contains a squirrel cage and bearings mounted to a stainless-steel shaft. The squirrel cage consists of circular end caps with rotor bars covered with steel laminations between them. The electromagnetic field generated by the stator fluctuates around the rotor, inducing opposing magnetic fields in the lamination-covered rotor bars, creating rotational motion.

The “squirrel cage” terminology comes from the fact that the rotor’s shape resembles a squirrel cage. If you haven’t seen many caged squirrels, then this may still cause some confusion. Apparently, long ago, squirrels were frequently kept as pets and would get exercise on a spinning wheel in their enclosure. Perhaps a more modern term for this type of rotor would be “hamster wheel” instead of “squirrel cage,” but we don’t expect the three-phase hamster wheel induction motor to catch on anytime soon.

Why is the three-phase squirrel cage induction motor so popular? It has quite a few advantages, including relatively low cost, ease of installation, high efficiency, low maintenance, and durability. These advantages are the reason that experts estimate that as many as 70% of industrial machines are driven by these motors today.

These popular induction motors can be found in just about every industrial setting you can imagine. Of course, they’re particularly useful in applications that require a low maintenance, constant-speed, low-torque motor that’s also self-starting, such as: machine tools (CNC and lathes); generators; fans and blowers; industrial drives; and centrifugal pumps.

It’s critical for any modern industrial maintenance technician to be thoroughly familiar with three-phase squirrel cage induction motors. How can educators and employers ensure that their workers possess the skills they need? DAC Worldwide offers a wide variety of electrical training systems specifically designed to give employees the hands-on experience they need to master different types of electrical motors, transformers, and more!

For example, DAC Worldwide’s Three-Phase, Squirrel Cage Rotor, AC Motor Training System (412-000) provides hands-on experience with a squirrel cage induction motor. Learners can use this training device to practice motor wiring by using banana jack receptacles on the control enclosure’s front panel face, study the motor’s construction, practice industrial motor maintenance skills by using fault insertion switches for hands-on troubleshooting training, and practice lock-out/tag-out (LOTO) procedures by using the system’s master circuit breaker.

DAC Worldwide’s training systems feature heavy-duty construction with real industrial equipment. Be sure to check out DAC Worldwide’s Electrical & Electronics Training Systems and contact a DAC Worldwide representative to learn how you can improve your training today!

- Published in News

DAC Worldwide Makes Industrial Maintenance Training Easy!

Industrial maintenance training for technicians in the oil and gas and petrochemical industries must teach them fundamental knowledge of and hands-on skills related to a wide variety of different types of valves that keep fluids flowing through vast networks of piping.

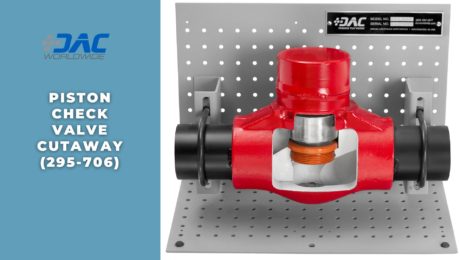

For example, different types of check valves help to prevent the reversal of fluid flow in piping systems. One specific check valve — the piston check valve — can often be found in systems that experience frequent changes in fluid flow direction.

Maintenance technicians will find piston check valves in all sorts of common applications, including: water, steam, and air systems; feed water control in nuclear facilities and steam power generation plants; freshwater supply; wastewater treatment; monitoring and sampling systems; dump lines; food and beverage processing; air conditioning systems; and pharmaceuticals and chemicals manufacturing.

Piston check valves contain a dash-pot with a cylinder and weighted piston or disc. These valves are activated by fluid flowing through a system. The pressure of the flowing fluid opens the valve, which allows unobstructed flow in one direction while fluid flow pressure remains constant.

When pressure decreases as fluid flow slows or reverses, gravity forces the piston to close the valve, preventing backflow. While piston check valves primarily rely upon gravity, the weight of the piston, and back pressure to force closure of the valve, some models also incorporate springs to assist with valve closure.

Piston check valves are popular because of their many advantages, including: durability; versatility; repairability; cost-effectiveness; efficiency; and ease of installation, maintenance, and repair. However, piston check valves are not suitable for applications requiring bi-directional fluid flow or pulsation fluid flow.

If you want to ensure your maintenance technicians have the skills to work with piston check valves, DAC Worldwide’s Piston Check Valve Cutaway (295-706) provides valuable classroom training in the operation, construction, and maintenance of industrial piston-type check valves.

DAC Worldwide’s valve cutaways use actual industrial valves that have been carefully sectioned and color-coded to expose and showcase the complete internal configuration of the valve. Seal features and hardware locations are retained, allowing for “hands-on” training in maintenance.

Moreover, common valve makes and models are chosen to ensure industrial relevancy. All cleaning, priming, and painting uses a high-durability urethane coating to ensure this training tool will last for years.

DAC Worldwide’s Piston Check Valve Cutaway features a welded-bonnet, socket-welded valve exactly like those commonly used in high pressure oil & gas production applications, providing unparalleled training to those involved in oil & gas production operations and maintenance training.

The Piston Check Valve Cutaway is only one of DAC Worldwide’s many oil and gas training cutaways. Visit DAC Worldwide online to learn more about other oil and gas training tools, such as the Diaphragm Dump Valve Cutaway, Oilfield Backpressure Regulator Cutaway, and many more!

- Published in News

Safety Leaders Reveal Most Significant Challenges in the Workplace

What would you consider to be the most foundational skillset in the industrial workplace? If you did not answer “safety,” there are safety leaders everywhere who would like a word with you. In fact, you may be part of the problem!

Safety leaders are tasked with making sure the industrial workplace is as safe as possible for workers. There’s no greater threat to industrial efficiency and productivity than workplace accidents that injure workers and cause costly delays and downtime.

As more and more advanced automation technologies enter the workplace, safety leaders constantly face new challenges to keep workers safe as they work alongside new machinery. But safety shouldn’t just be the concern of a few leaders. All employees need to make safety a top priority.

According to a recent EHS Today article by Dave Blanchard and Nicole Stempak, “EHS Today’s National Safety and Salary Survey 2023 invited respondents (all of them EHS professionals) to share comments regarding their job situation, the safety profession, and the biggest professional challenges that they face.” Here are some of the top challenges identified by the nation’s safety leaders:

- Finding qualified employees

- The transition from a human-based workforce to a technology-based workforce

- Safety buy-in from the younger workforce

- Senior leadership buy-in

- Mental well-being

- Too many rules and regulations

- Profit over safety

- Training and job knowledge

- Employee turnover

- Older supervisors are retiring faster than we can train replacements to take their place

- Employee complacency

- Doing too much too fast

- Finding employees with the proper skillsets

- Keeping the workforce actively engaged in their own safety

As you can see, safety leaders face a wide variety of challenges in the modern industrial workplace. What can be done to improve a workplace’s safety culture? How can leaders influence others to prioritize safety, leading to fewer accidents? One solution is to implement a quality safety program that teachers workers the knowledge and skills they need to stay safe in the workplace.

One of the most basic—and important—areas to focus on is the control of hazardous energy, often known by its more popular moniker “lock-out/tag-out or LOTO.” According to the United States Department of Labor’s Occupational Safety and Health Administration (OSHA), “[e]nergy sources including electrical, mechanical, hydraulic, pneumatic, chemical, thermal, or other sources in machines and equipment can be hazardous to workers. During the servicing and maintenance of machines and equipment, the unexpected startup or release of stored energy can result in serious injury or death to workers.”

“Workers servicing or maintaining machines or equipment may be seriously injured or killed if hazardous energy is not properly controlled…Injuries may include electrocution, burns, crushing, cutting, lacerating, amputating, or fracturing body parts… Craft workers, electricians, machine operators, and laborers are among the millions of workers who service equipment routinely and face the greatest risk of injury.”

Fortunately, “[p]roper lock-out/tag-out practices and procedures safeguard workers from hazardous energy releases.” Teaching workers hands-on LOTO skills will help them to understand how to properly control hazardous energy and maintain a safe work environment.

For companies looking to improve their safety training, a thorough review of current training materials is a great place to start. Do employees have access to hands-on training with actual components they’ll encounter on the job? If not, partnering with established companies to provide industrial-quality training systems that will stand the test of time will help ensure the continued safety of the workforce.

For example, DAC Worldwide offers a safety training system specifically designed to give employees the hands-on experience they need to master lock-out/tag-out skills. Be sure to check out DAC Worldwide’s Lock-Out/Tag-Out Training System and contact a DAC Worldwide representative to learn how you can improve your training today!

- Published in News

DAC Worldwide Provides Unique Oil & Gas Training Tools

From operators and technicians to mechanics and engineers, oil and gas workers need knowledge and hands-on skills related to a wide variety of common industrial components they’ll encounter in the field. For example, a typical oil and gas worker will interact with a range of pumps and valves on a daily basis.

One such component workers will need to understand is a type of valve known as a back pressure regulator. Back pressure regulators are normally closed valves that precisely control and limit the upstream pressure in a system.

Back pressure regulators maintain a steady upstream pressure of any fluid, gas, liquid, or mixture in a system. They regulate system pressure by adjusting position, widening or narrowing to relieve or increase pressure. Usually installed at the end of a line or process, back pressure regulators ensure that all equipment used before the back pressure regulator receives the correct pressure, maintaining the integrity and effectiveness of the process.

When used in a well head, back pressure regulators control the flow of fluids or gases in the well. The back pressure regulator opens or closes with changes in the pressure of the fluid or gas, preventing overpressure within the well and protecting equipment and personnel from damage or injury. A wellhead back pressure regulator can also be used to maintain a specific pressure in a well for production or injection operations.

To teach oil and gas workers about these common components, DAC Worldwide’s Wellhead Backpressure Regulator Cutaway (295-703) is a sectioned specialty regulator sample that provides convenient classroom and laboratory training in the operation, construction, and maintenance of three industrial back pressure regulator (BPRs), as used in gas and oil service in the oilfield.

These common regulators are often used to maintain steady pressure on an oil column or to assure continuous flow of a producing low pressure well. They’re also regularly found in Xmas tree assemblies in the oilfield.

Through carefully planned sectioning and color-coding, the complete internal configuration of the regulating valve is exposed and showcased. Seal features and hardware locations have been retained, allowing for hands-on training in maintenance. These valves, commonly used in oil & gas production applications and commonly encountered in production wellheads and Xmas trees, are an essential part of comprehensive oil and gas production training.

The Wellhead Backpressure Regulator Cutaway is only one of DAC Worldwide’s many oil and gas training tools. Visit DAC Worldwide online to learn more about other oil and gas training aids, such as the Diaphragm Dump Valve Cutaway, Piston Check Valve Cutaway, Vertical Separator Trainer, and many more!

- Published in News

DAC Worldwide Training Tool Provides Unique Insight into Common Valve

Today’s oil and gas workers need in-depth knowledge of and hands-on experience with a wide variety of different types of industrial valves commonly used in the oil and gas sector. When problems arise at an oil refinery, for example, you want skilled technicians able to troubleshoot and repair systems quickly to avoid a potentially dangerous situation.

One of the most common process controllers you’ll find in oil and gas facilities is the liquid level controller. This key device maintains the level of oil or gas in a container by opening or closing a valve known as a liquid dump valve.

Since the liquid dump valve is located near the level measurement device, it’s possible to use mechanical linkages to coordinate the position of a liquid level float in an oil and gas separator with the position of the liquid dump valve.

In a typical mechanical liquid level controller, the liquid level float that sits atop the liquid is connected to a rod that, in turn, connects to the liquid dump valve. As oil or gas level increases or decreases, the float moves the rod that then opens or closes the liquid dump valve.

For example, if the level of oil in a separator increases, the float will rise, causing the rod to open the liquid dump valve to release oil. Then, as the liquid level decreases and the float lowers, the rod will cause the liquid dump valve to begin to close to decrease the rate of liquid release.

Lever-operated dump valves can be found in a wide variety of oil and gas production containers, including separators, accumulators, treaters, and free water knockouts. To teach oil and gas workers how to maintain, troubleshoot, and repair these common valves, DAC Worldwide’s Lever-Operated Dump Valve Cutaway (295-705) is an actual industrial lever-operated oil dump valve that has been carefully sectioned and color-coded to expose and showcase the complete internal configuration of the valve.

Seal features and hardware locations have been retained, allowing for hands-on training in maintenance. Moreover, common valve makes and models are chosen to ensure industrial relevancy. All cleaning, priming, and painting uses a high-durability urethane coating to ensure this training tool will last for years.

The Lever-Operated Dump Valve Cutaway is only one of DAC Worldwide’s many oil and gas training cutaways. Visit DAC Worldwide online to learn more about other oil and gas training tools, such as the Diaphragm Dump Valve Cutaway, Piston Check Valve Cutaway, Oilfield Backpressure Regulator Cutaway, and many more!

- Published in News