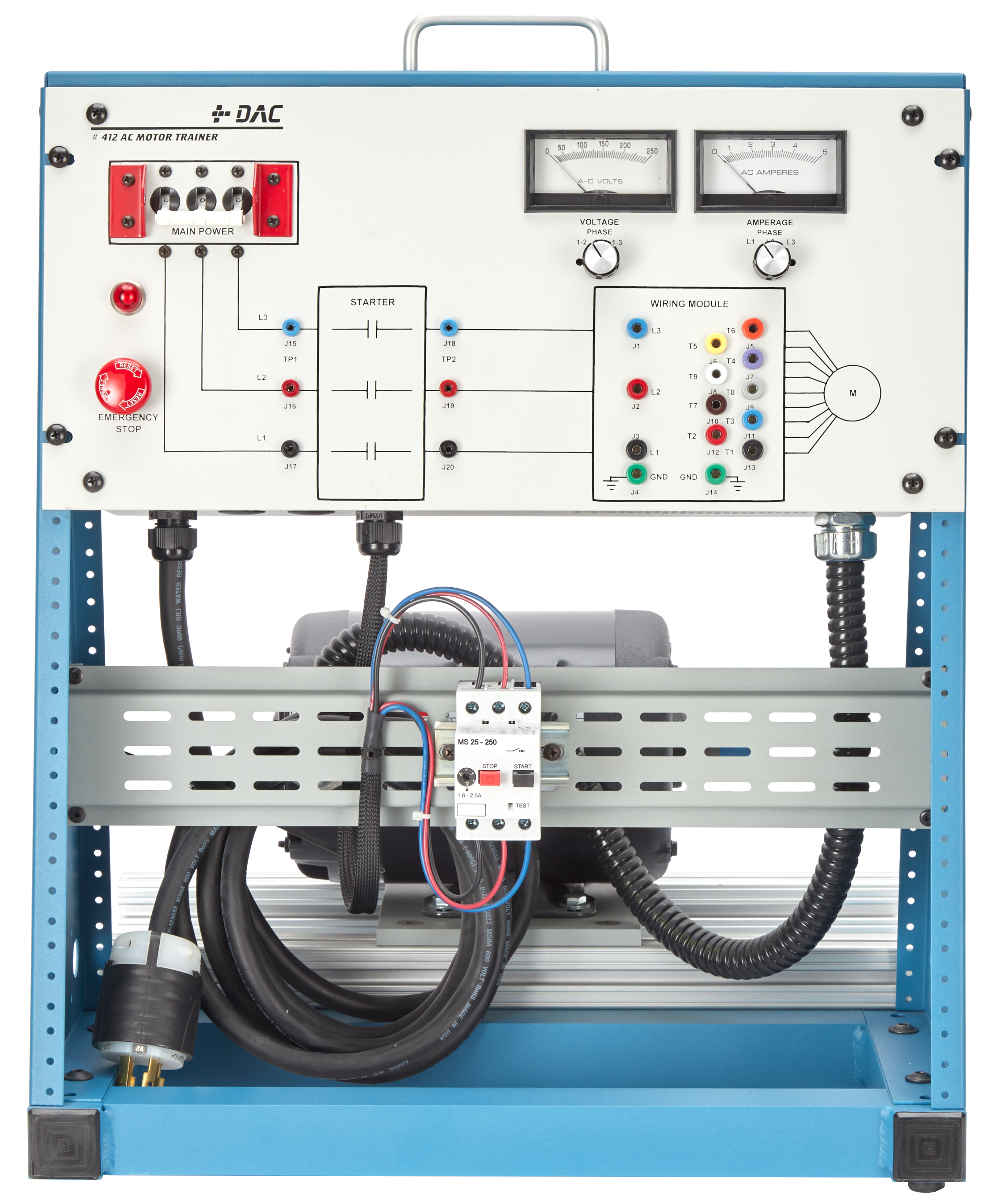

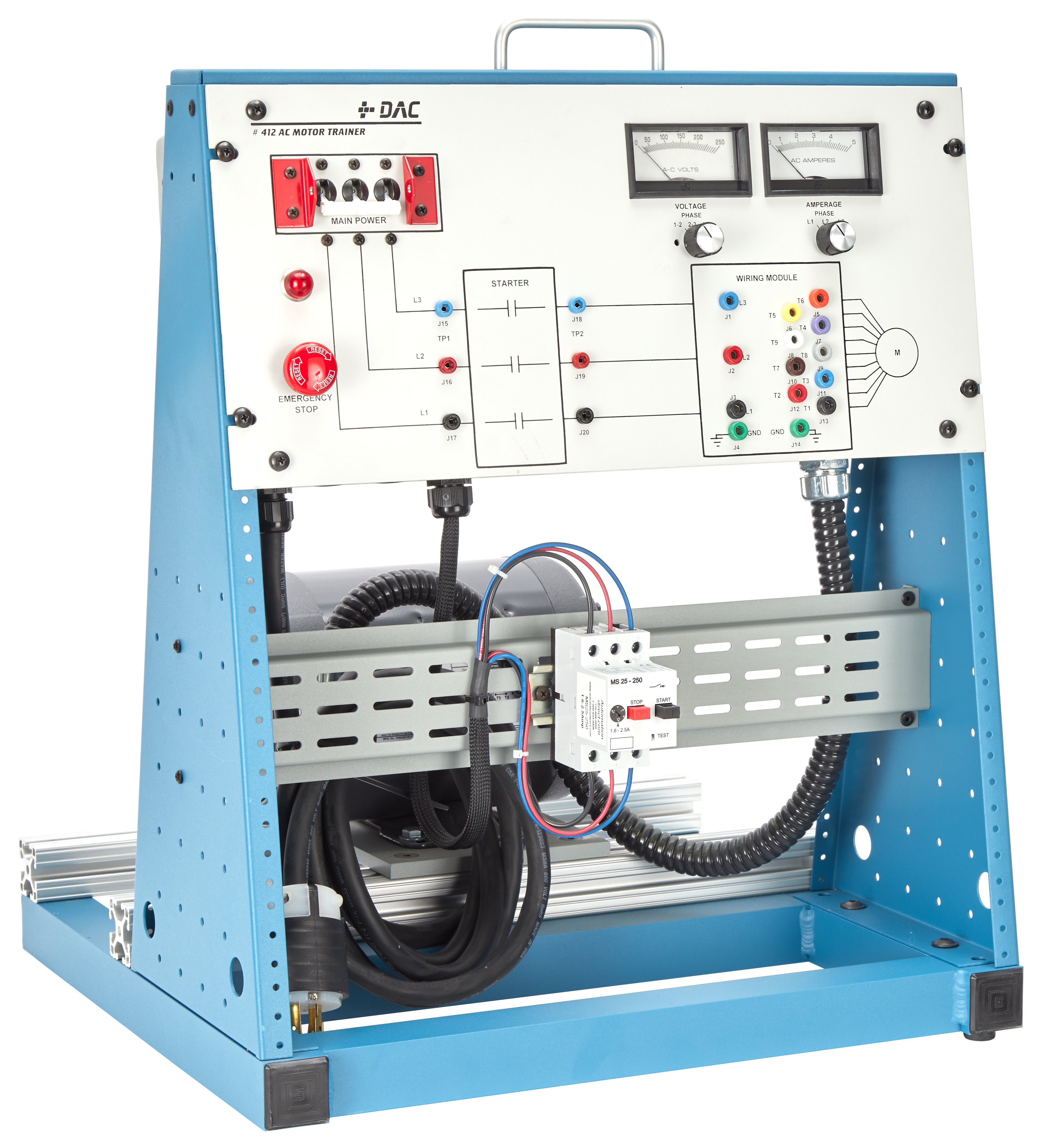

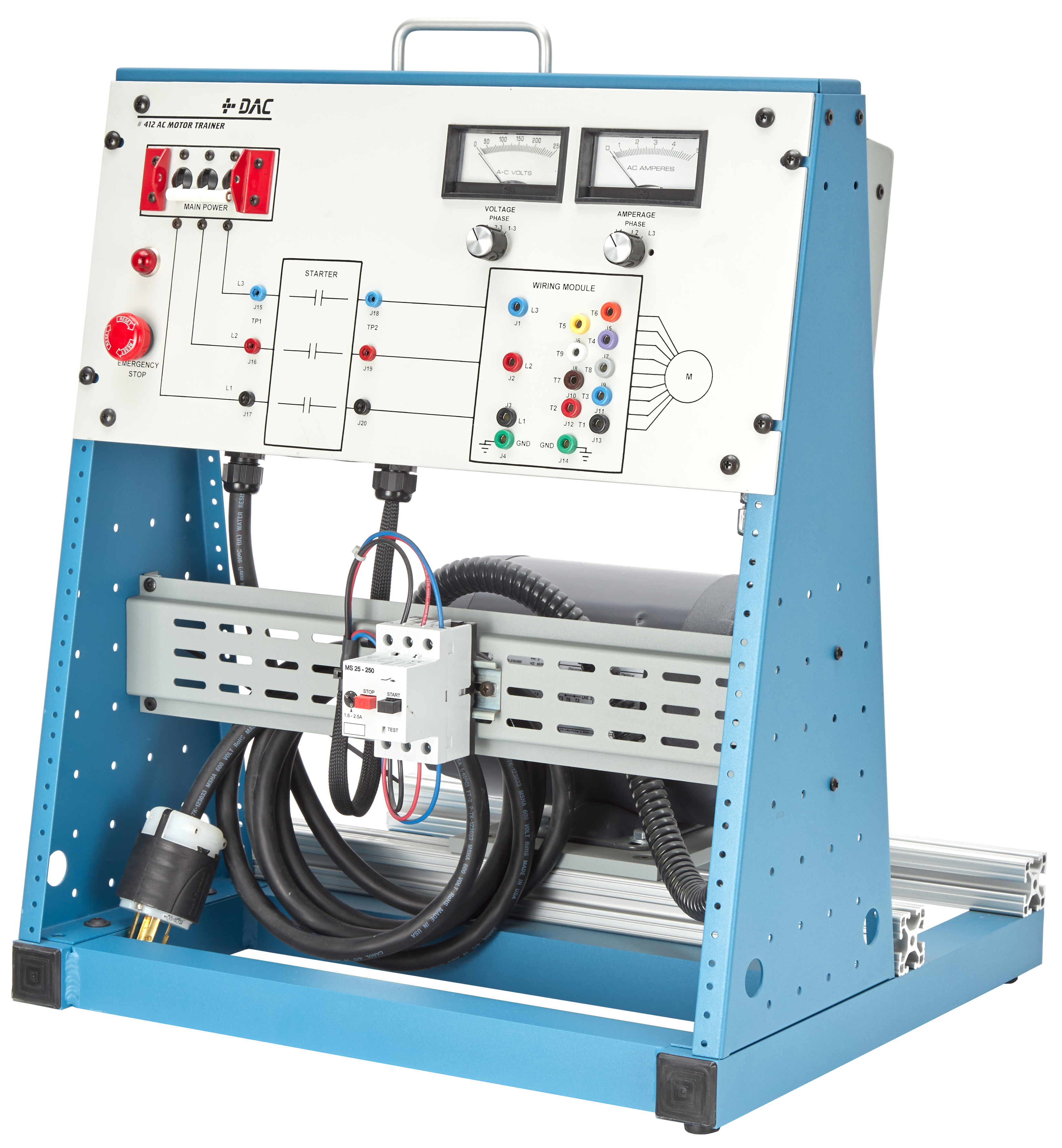

- Welded aluminum baseplate

- Provision for bench-top mounting

- Motors mounted on T-slotted rails which accommodate 184T and 56 frame motors (56 frame standard)

- Master circuit breaker with lock-out / tag-out capability

- Silkscreened panel face with identification of line and motor lead numbers

- Color-coded banana-jack patch cord receptacles

- Voltmeter and ammeter

- Permanent internal grounding of all elements

- Enclosure cover safety interlock switch

- Four instructor fault insertion switches (on rear of control enclosure)

- Large emergency stop switch

- Keyed instructor power switch (on rear of control enclosure).

- Large pilot light

DISCLAIMER: Product Dimensions are approximate. Shipping Dimensions and Weights are for directional use only and may change based on manufacturer variables. For the most accurate Shipping Dimensions and Weights, please contact the manufacturer.

- 19-in. L x 19-in. W x 25-in. H (480 x 480 x 640 mm)

- 50lbs. (23kg)

- #410-001/E - Portable Digital Multimeter

- #410-002 - Non-Contact Tachometer Kit

- #410-100 - Prony Brake Assembly

- Optional Use with #210 Electromechanical Trainer Package

- Motor

- Circuit Breaker

- Voltmeter

- Ammeter

- Safety Interlock Switch

- Four (4) Instructor Fault Insertion Switches

- E-Stop

- Large Pilot Light

- Keyed Instructor Power Switch

- #410-500 - Use/Exercise Guide