Learn Essential Motor Control Skills with DAC Worldwide’s Hands-On Training Systems

Industrial machinery requires a wide variety of different types of motors to function efficiently and effectively. Whether they’re powering a compressor, pump, fan, or conveyor, three-phase induction motors keep operations at industrial facilities moving steadily.

Many induction motors require significant power given their heavy-duty applications. Moreover, they draw a high electrical current upon start-up. In fact, start-up current can sometimes be as much as 5-6 times what they draw at normal operating speed. This is why they require a special device called a motor starter.

If industrial motors relied solely on circuit breakers or fuses, those would trip or blow every time the motor started. That’s obviously unacceptable in an industrial setting. Instead, specialty motor starters start and stop induction motors using manual or automatic switches. They also protect motor circuits from excessive heat caused by overloads during normal operations.

Motor starters consist of two primary parts: (1) an electromagnetically operated set of contacts (called a contactor) starts and stops the motor by beginning or ending the flow of electrical current; and (2) an overload relay that protects the motor from drawing too much current and overheating.

Likewise, motor starters usually consist of two circuits: (1) a power circuit that transmits the primary voltage to the motor via the starter contacts and overload relay; and (2) a control circuit that manages the contactor coil that creates the electromagnetic field that operates the power contacts.

Because there are so many different types of industrial applications that require induction motors, there are likewise a wide variety of different types of motor starters. One common type is the reversing magnetic motor starter. Reversing starters, as their name implies, are specifically designed to efficiently reverse shaft rotation of a three-phase induction motor.

Reversing starters work by interchanging two contactors supplying electrical current to the motor, as well as having both a forward and a reverse starter. To ensure that only one of the starters can be engaged at any particular time, reversing starters feature both mechanical and electrical interlocks for enhanced safety.

Industrial maintenance technicians must be familiar with all sorts of induction motors and their motor starters. Hands-on training in electrical maintenance can elevate your technicians’ skills to the next level.

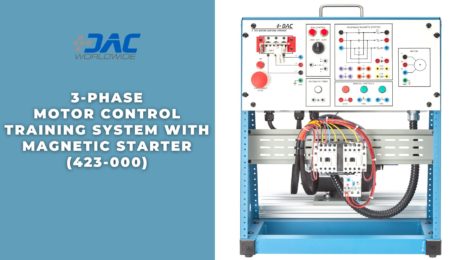

For example, if you want to ensure your maintenance technicians have the skills to work with reversing magnetic motor starters, DAC Worldwide’s 3-Phase Motor Control Training System with Magnetic Starter (423-000) offers comprehensive training in the operational principles, wiring, fault troubleshooting, and application of industrial three-phase, reversing magnetic motor starters.

The 3-Phase Motor Control Training System with Magnetic Starter is self-contained, allowing for individual study by a single student or a small student group. While often used independently, the training aid can be integrated with other optional products relating to programmable controllers, pilot devices, and motor-driven mechanical systems.

This electrical trainer includes a variety of industry-standard components, including: a three-phase induction motor; reversing magnetic motor starter with auxiliary contacts, mechanical and electrical interlocks, and overload relay; on-board wiring devices including Hand-Off-Auto (HOA) control station, manual control station, and automatic timer; color-coded, shielded banana-jack receptacles for all motor leads, supply connections, and control components; circuit breaker with lock-out/tag-out; keyed power switch; pilot light and emergency stop switch; and four instructor fault switches to create common component faults for troubleshooting instruction.

The 3-Phase Motor Control Training System with Magnetic Starter is only one of DAC Worldwide’s many electrical training systems. Visit DAC Worldwide online to learn more about other electrical training systems, such as the Three-Phase, Squirrel Cage Rotor, AC Motor Training System; 1-Phase Motor Control Training System with Manual Starter; DC Permanent Magnet Motor Control Training System; and many more!

- Published in News

Fundamental Electrical Skills Training: Powering the Path to Success

No matter their experience, skill level, or desired specialty, all individuals aspiring to become electrical professionals need the same fundamental electrical skills. These include understanding the basic principles of electricity and working with common electrical components, such as wiring, motors, and circuits. By mastering core skills like these, learners can help ensure they work safely and efficiently in whatever specified path they choose, whether that is industrial, commercial, or residential electrical careers.

As with any discipline, learning fundamental skills establishes a foundation from which a learner can build more complex concepts and skills. An electrician who now wires entire buildings for manufacturing processes was once a student learning about electric current. Furthermore, that same electrician could choose to expand their skills into more advanced or niche areas, such as performing industrial maintenance for the robotic arms they run power to, which would require that they rely on their understanding of basic PLC operation to progress to the complex coding needed to ensure manufacturing level precision.

Additionally, an electrical technician’s understanding of basic concepts and their abilities helps build confidence that translates to efficiency. For example, an HVAC technician is able to quickly restore air conditioning to a home because they understand how the circuit board, fan motor, compressor, and other components work both individually and together to create a working system. However, if the technician did not have a knowledge of wiring practices, the job would move much more slowly and, if done wrong, could even be dangerous.

In the same vein, industrial workers that know the do’s and don’ts of electrical practices can help recognize and prevent risky electrical setups. This makes a workplace safer for everyone and can help a company avoid downtime. In essence, fundamental electrical skills help prepare future technicians of many career paths to handle any job they will face in the field and provide the first step in pursuing a successful career in the electrical field.

DAC Worldwide’s Electrical Training Systems

DAC Worldwide offers many training systems that teach learners the fundamental electrical skills they need for a successful career. Each trainer is compact and sturdy, allowing for ease of relocation and longevity of use. By using these systems, learners will practice crucial hands-on skills related to focused electrical topics. Below, we’ve included a sampling of our most popular electrical trainers.

400-PAC – Modular Basic Electricity Training System Plus

The 400-PAC covers basic AC and DC electrical principles, including installation, operation, and troubleshooting for multiple applications. Learners can expect to gain a greater understanding of how electricity is used for power and control in industrial, commercial, and residential settings.

This trainer uses 43 activities to engage learners in lessons covering topics such as terminology, background theory, component examination and testing, circuit design, and more. A built-in circuit breaker, transformer, and internal power supply create working voltages of 24VAC/24VDC. This allows learners to gain hands-on experience with skills like calculating and regulating voltage in a circuit, operating a clipper circuit and full-wave bridge rectifier, loading dry cells, utilizing indicator lamps and toggle switches, and much more.

420-000 – 1-Phase Motor Control Training System with Manual Starter

The 420-000 is a single-topic trainer that allows learners to focus solely on navigating the operation, wiring, troubleshooting, and application of an industrial single-phase AC motor with a manual starter. With redundant safety systems provided and a keyed instructor power switch, learners can safely study individually or in small groups.

The system also comes equipped with a motor, manual motor starter, circuit breaker, electrical interlock, pilot light, e-stop switch, and four instructor fault switches. Learners use shielded banana-jack connections to wire the motor. While self-contained, the trainer may be expanded with supplemental components, such as a piloting switch module and a motor loading device, to teach additional topics.

The system also comes equipped with a motor, manual motor starter, circuit breaker, electrical interlock, pilot light, e-stop switch, and four instructor fault switches. Learners use shielded banana-jack connections to wire the motor. While self-contained, the trainer may be expanded with supplemental components, such as a piloting switch module and a motor loading device, to teach additional topics.

422-000 – 3-Phase Motor Control Training System with Manual Starter

Like the 420-000, the 422-000 is a self-contained, single-topic trainer that allows for independent or small group study. Multiple components, such as a keyed instructor power switch, permanent internal grounding, circuit breaker with lock-out/tag-out, and a large emergency stop switch, ensure learner safety. All equipped components are UL and CE certified.

This trainer offers 21 activities for learners to practice hands-on skills for operating, wiring, and troubleshooting an industrial three-phase AC motor with a manual starter. Some examples of these skills include wiring a three-pole pushbutton motor starter as a motor controller and employing the instructor fault switches to troubleshoot a drum-type reversing switch manual starter.

429E – AC Variable Frequency Drive Training System Plus

The 429E uses industrial-grade components, such as an industrial 3-phase motor and an Allen-Bradley PowerFlex 40 variable frequency drive, to teach AC drive programming, system troubleshooting, control wiring, and other industry-relevant skills. Various inputs and outputs and a programmable acceleration/deceleration with an on-board PID control loop allow learners further practice in understanding voltage, relay, resistance, and amperage.

Other course content includes topics like minimum and maximum frequency, jog parameters, skip frequency bandwidth, and checking and setting acceleration and deceleration timing. Eight fault insertion switches provide thorough real-time troubleshooting practice.

461-000 – Basic PLC Training System (AB Micro850)

The 461-000 provides a wealth of information for learners to develop a firm understanding of industrial PLCs, with emphasis on the current generation Allen-Bradley Micro850. This trainer features eight DC input switches, eight DC output LED lights, two 25-pin D-Sub input/output connectors, multiple safety components, and more. Eight fault insertion switches are also built into the system to help learners increase their proficiency with PLC troubleshooting.

An optional textbook offers more study for relevant topics, such as introducing Boolean algebra and Veitch diagrams, understanding logic gates, creating subroutines and sequencers, and much more. The trainer can also be expanded by connecting it to other training systems that teach process control, sensors, motor control, fluid power, and more.

Boost Your Electrical Training Program Today

We aim to make training more memorable and effective so future electrical technicians can thrive in their chosen career paths. For more information on which training aide may best fit your needs, contact a DAC Worldwide consultant today.

- Published in News