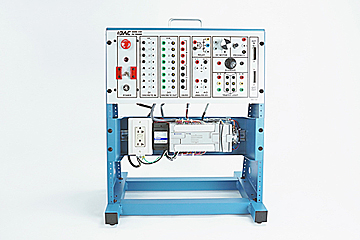

- 16-Gauge, formed-steel mounting frame

- Welded, steel bar mounting base assembly with rubber feet

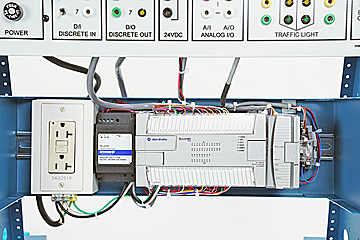

- Convenient DIN-rail PLC mounting

- On-board 110/220 VAC Service outlet (for PC or laptop power)

- On-board 24 VDC power supply (1.2 A)

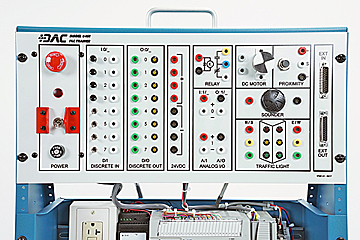

- Eight (8) On-board fault insertion switches

- On-board applications include: sounder, DC motor, proximity switch, multi-use relay, and traffic light application

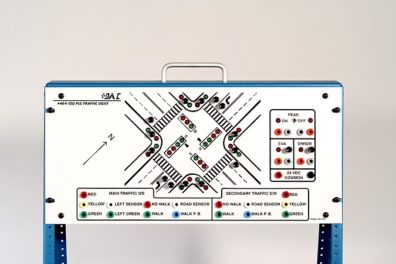

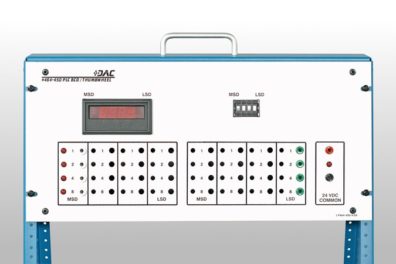

- 1/8" Aluminum powder-coated and Silk-screened 19" rack-mount panel face

- All steel and aluminum components powder-coated for durability

- Master power switch with provision for lock-out/tag-out

- Pilot light and emergency stop switch

- System push-button circuit breaker

- Eight (8) DC input switches, including toggle, momentary and latching push-button varieties

- Eight (8) DC output LED lights

- Provision for connection to external applications via banana jack receptacles including:

- Eight (8) DC inputs

- Eight (8) DC outputs

- Two (2) 25-pin, D-Sub input/output connectors (DB25)

- Provision for accessing optional analog card, including:

- Four (4) analog input banana jack receptacles

- Four (4) analog output banana jack receptacles

- Formed-steel, and powder-coated PLC, power supply DIN-rail mounting bracket

- Allen-Bradley Micro850 assembly

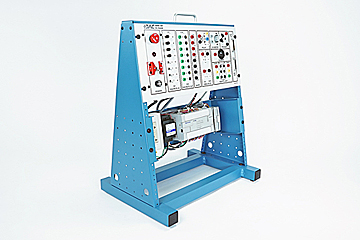

- Carrying handle

- Provision for direct mounting on related electromechanical bench and workstation products

- Allows for connection to training products relating to process control, motors/motor control, sensors, PLC applications and fluid power

- Crating for shipment via motor freight

- Allen-Bradley Micro850 Programmable Controller

- Connected Components Workbench (CCW) Software DVD

- Power Supply

- Fault Insertion Switches

- Sounder

- DC Motor

- Proximity Switch

- Multi-Use Relay

- Traffic Light Application

- Pilot Light and E-Stop Switch

- DC Input Switches

- DC Output Lights

- #461-500 Use/Exercise Guide

The courseware, useful in both a instructor-led and or a self-directed format, includes one of several optional textbooks, a course guide and hands-on exercises.

Exercises include:

- Review of Electronic Concepts Related to PLCs

- Introduction to PLC Components, Terminology, and Applications

- Introduction to Numbering Systems Used in PLCs

- Understanding Logic Gates

- Introduction to Boolean Algebra

- Introduction to Veitch Diagrams

- Introduction to Ladder Logic

- Introduction to the DAC #461 PLC Trainer

- Introduction to the Allen-Bradley MicroLogix 1200 PLC

- Using RSLogix 500 to Program the MicroLogix 1200

- Working with Projects

- Using External Input and Output Elements

- Using Internal Bits

- Using Latching Logic Instructions

- Forcing External Bits on the MicroLogix 1200 PLC

- Using Timer Instructions

- Using Counter Instructions

- Using Arithmetic Instructions

- Using Jump Instructions

- Creating Subroutines

- Creating Sequencers

DISCLAIMER: Product Dimensions are approximate. Shipping Dimensions and Weights are for directional use only and may change based on manufacturer variables. For the most accurate Shipping Dimensions and Weights, please contact the manufacturer.

- Product Dimensions

(L x W x H)

14" x 20" x 23" (350 x 500 x 580 mm)

28lbs. (12 kg) - Shipping Dimensions

(L x W x H)

15.25" x 23.5" x 31" (385 x 597 x 787mm)

48 lbs (22 kg)

- 115V/60 Hz/1Ph