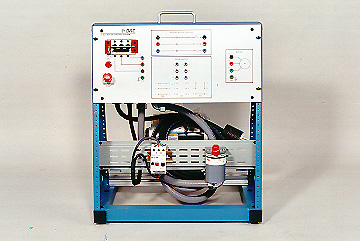

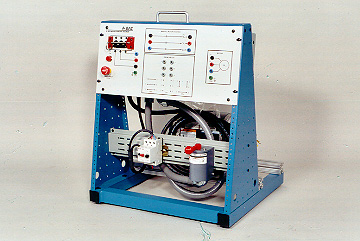

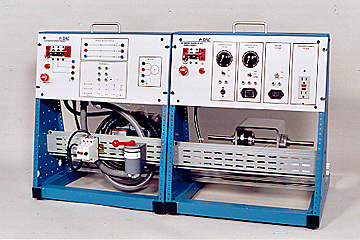

- Welded aluminum base assembly using 1-1/2" square, 1/8" wall aluminium tubing

- Aluminum t-slotted mounting rails, allowing for attachment of tethered motor/baseplate assembly and connection to associated devices

- 16-Gauge formed-steel support structure allowing for attachment to base assembly or alternate mounting bench and integration products

- 16-Gauge formed-steel electrical enclosure

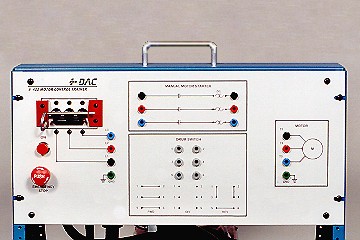

- Silk-screened 1/8" aluminum front panel face

- Powder-coated surfaces throughout

- On-board safety components, including:

• Keyed instructor power switch (rear of product)

• Circuit breaker with provision for representative lock-out/tag-out

• Permanent, redundant, internal grounding (not dependent on student wiring)

• Pilot light and large emergency stop switch

• Internal electrical interlock, de-energizing power when accessing electrical enclosure

• Industrial-duty, 56-frame, 1/2 HP, 1725 RPM, three-phase induction motor

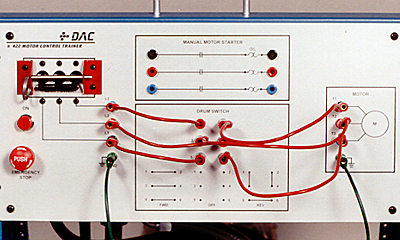

• 3-Pole manual motor starter with variable thermal overload

• On-board reversing drum switch - Use of UL and CE certified electrical components throughout

- Color-coded, banana-jack receptacles for all motor leads, supply connections and control components

- Four (4) instructor fault switches (rear of device, behind access panel)

- Allows for attachment to optional control and mechanical devices directly and using optional integration bench products

- Packaging for shipment via motor freight

- Manual Motor Starter

- Circuit Breaker

- Keyed Instructor Power Switch

- Pilot Light and E-Stop Switch

- Electrical Interlock

- Motor

- Four (4) Instructor Fault Switches

- #420-500 Use/Exercise Guide

DISCLAIMER: Product Dimensions are approximate. Shipping Dimensions and Weights are for directional use only and may change based on manufacturer variables. For the most accurate Shipping Dimensions and Weights, please contact the manufacturer.

- Product Dimensions

(L x W x H)

19in. x 19in. x 25in. (480 x 480 x 670 mm)

50 lbs. (22.5 kg) - Shipping Dimensions

(L x W x H)

20.75" x 23.5" x 30" (525 x 600 x 760 mm)

85 lbs. (32.5 kg)

- 208V/60Hz/3Ph