Today’s industrial facilities feature a wide array of different types of machines, from simple pumps to complex automated robots. One of the most common machines you’ll find in any industrial setting is the electric motor.

Simple, versatile, and available in many different configurations, electric motors carry the burden of converting electrical energy into mechanical energy. At the most basic level, electric motors can be distinguished based upon their power source: direct current (DC) or alternating current (AC).

For industrial use, the most common type of electric motor is the AC induction motor (also known as an asynchronous motor). The name “induction” is used because electrical current is induced in the rotor rather than supplied externally. The popularity of the AC induction motor stems from its simplicity, relatively low cost, and excellent reliability in a wide range of applications.

Induction motors can be further divided into two primary types: single-phase and three-phase, depending upon the type of electricity used to power them. The most-used electric motor throughout industry is arguably the three-phase squirrel cage induction motor.

Squirrel cage motors rely upon electromagnetic induction to create motion by converting electrical current into rotational energy. AC current travels through the stator, the stationary portion of the motor that consists of the housing and a series of windings (usually copper). The three-phase AC power energizes the windings, creating a rotating electromagnetic field.

The rotating part of the motor, known as the rotor, sits inside the stator. It contains a squirrel cage and bearings mounted to a stainless-steel shaft. The squirrel cage consists of circular end caps with rotor bars covered with steel laminations between them. The electromagnetic field generated by the stator fluctuates around the rotor, inducing opposing magnetic fields in the lamination-covered rotor bars, creating rotational motion.

The “squirrel cage” terminology comes from the fact that the rotor’s shape resembles a squirrel cage. If you haven’t seen many caged squirrels, then this may still cause some confusion. Apparently, long ago, squirrels were frequently kept as pets and would get exercise on a spinning wheel in their enclosure. Perhaps a more modern term for this type of rotor would be “hamster wheel” instead of “squirrel cage,” but we don’t expect the three-phase hamster wheel induction motor to catch on anytime soon.

Why is the three-phase squirrel cage induction motor so popular? It has quite a few advantages, including relatively low cost, ease of installation, high efficiency, low maintenance, and durability. These advantages are the reason that experts estimate that as many as 70% of industrial machines are driven by these motors today.

These popular induction motors can be found in just about every industrial setting you can imagine. Of course, they’re particularly useful in applications that require a low maintenance, constant-speed, low-torque motor that’s also self-starting, such as: machine tools (CNC and lathes); generators; fans and blowers; industrial drives; and centrifugal pumps.

It’s critical for any modern industrial maintenance technician to be thoroughly familiar with three-phase squirrel cage induction motors. How can educators and employers ensure that their workers possess the skills they need? DAC Worldwide offers a wide variety of electrical training systems specifically designed to give employees the hands-on experience they need to master different types of electrical motors, transformers, and more!

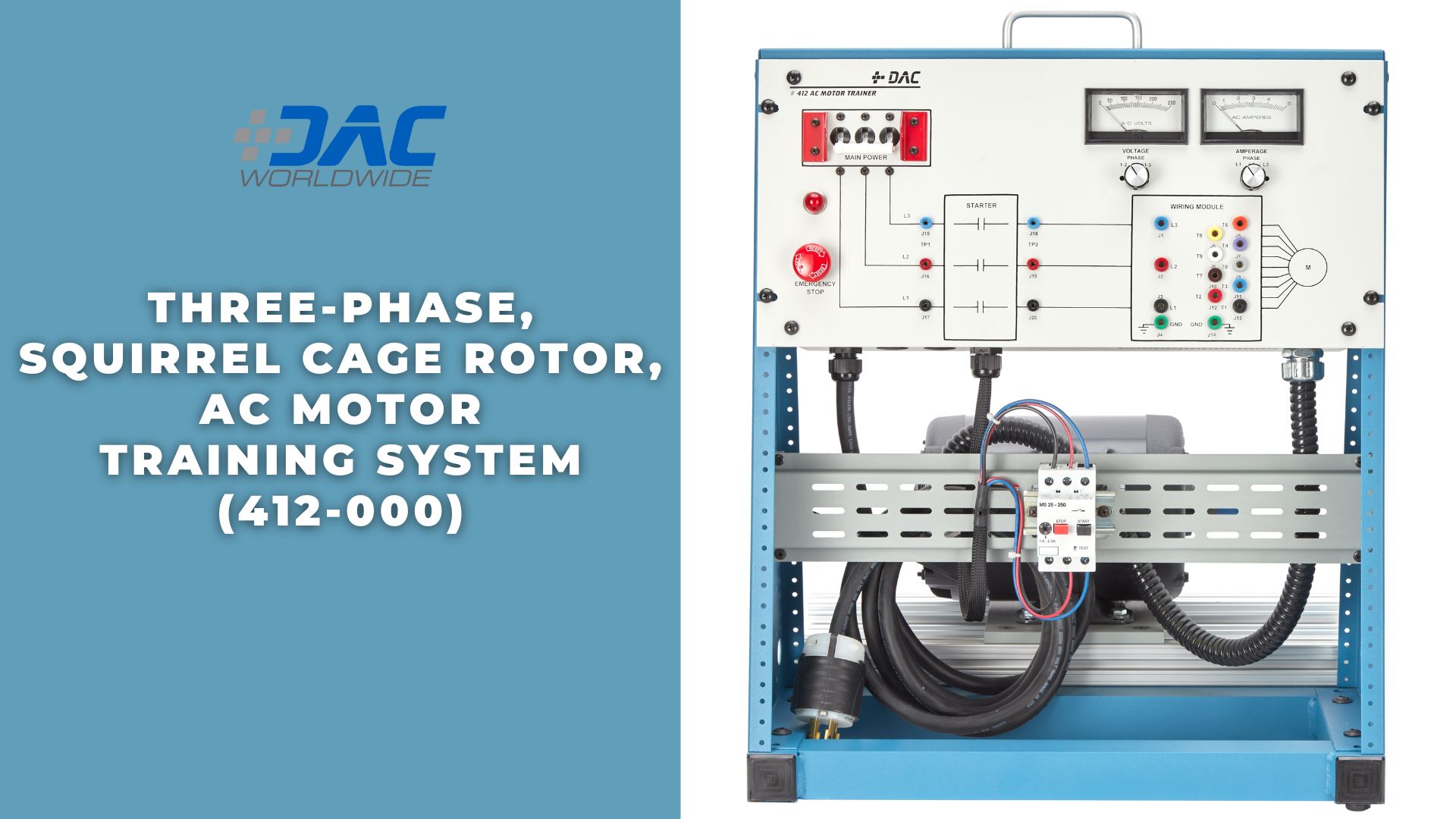

For example, DAC Worldwide’s Three-Phase, Squirrel Cage Rotor, AC Motor Training System (412-000) provides hands-on experience with a squirrel cage induction motor. Learners can use this training device to practice motor wiring by using banana jack receptacles on the control enclosure’s front panel face, study the motor’s construction, practice industrial motor maintenance skills by using fault insertion switches for hands-on troubleshooting training, and practice lock-out/tag-out (LOTO) procedures by using the system’s master circuit breaker.

DAC Worldwide’s training systems feature heavy-duty construction with real industrial equipment. Be sure to check out DAC Worldwide’s Electrical & Electronics Training Systems and contact a DAC Worldwide representative to learn how you can improve your training today!