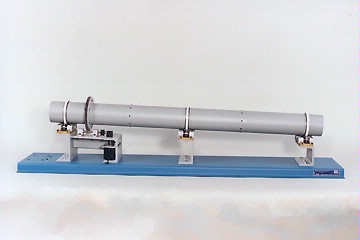

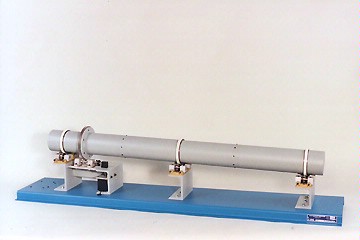

- 7-Gauge, formed-steel baseplate with provision for tabletop mounting

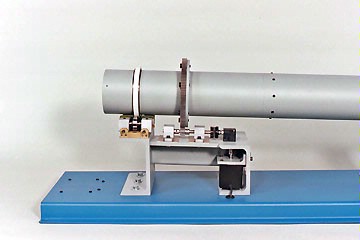

- Provision for attachment of magnetic base/dial indicator sets throughout

- Adjustable support feet

- Kiln tube, machined from schedule 80 steel pipe in three sections and allowing for adjustment of primary centerline using set screws

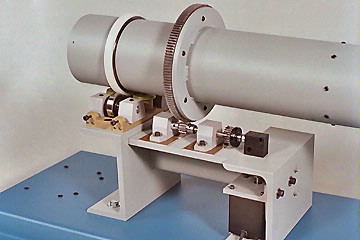

- Welded aluminum drive and roller assembly foundations

- Three (3) roller assemblies, including: detailed soldered brass substructures, adjustable roller pillow blocks, roller shafts and ball bearing rollers

- Nylon roller riding rings

- Representative kiln gear and pinion, with provision for adjustment and alignment

- Gear motor and associated electrical components

- High-durability urethane coatings throughout

- Crating for shipment via motor freight

DISCLAIMER: Product Dimensions are approximate. Shipping Dimensions and Weights are for directional use only and may change based on manufacturer variables. For the most accurate Shipping Dimensions and Weights, please contact the manufacturer.

- Product Dimensions

(L x W x H)

66in. x 13.5in. x 12in. (1670 x 340 x 300 mm)

175lbs. (80kg) - Shipping Dimensions

(L x W x H)

70in. x 18.5in. x 30in. (1778 x 470 x 762 mm)

261lbs. (118kg)

- Combination wrench set

- Feeler gauge set

- Allen wrench set

- Shim stock

- Requires 115V/60Hz/1Ph power

- #208-015 - Magnetic Base/Dial Indicator Set