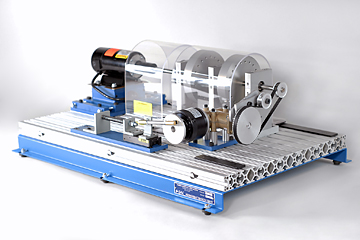

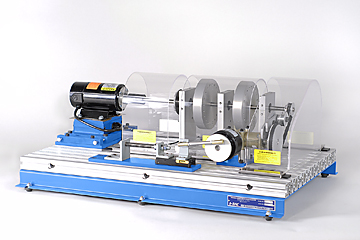

- 1/3 HP, 3450 RPM, inverter-duty, 3-phase, AC motor.

- Precision SCR speed control.

- Digital RPM indicator with magnetic pick-up.

- Heavy-duty, formed-steel, powder-coated baseplate weldment with adjustable feet.

- Aluminum, t-slotted component mounting surface.

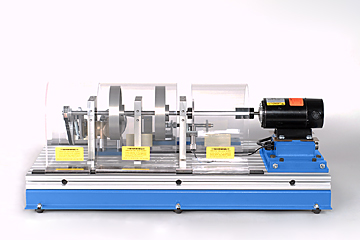

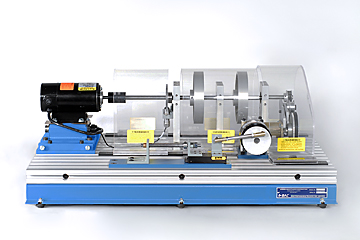

- Three, precision-machined split pillow blocks.

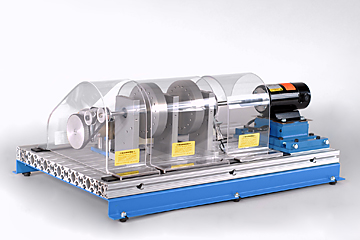

- Two, precision-machined rotors, allowing for the study of single plane, dual plane and overhung imbalance.

- Jack-shaft assembly incorporating positive drive belts, related sheaves, idler, and gears.

- Right angle gear reducer.

- Magnetic brake (adjustable).

- Connecting arm/linear slide assembly, allowing for study of vibration in conjunction with reciprocating motion.

- Provision for creating rotor imbalance using set screws/washers or clay on rotor rims.

- Three, ½" diameter, precision-ground shafts of different lengths.

- Precision, helical-beam coupling standard.

- Provision for attachment of vibration pick-ups via 1/4-28 studs throughout.

- Steel baseplate mounting strips allowing for attachment of standard accessories, and modular guards.

- Keyed instructor switch.

- Motor mounting sub-base with tapered alignment pins, allowing for re-positioning and easy return to aligned position.

- Fine-thread motor jacking bolts.

- High-durability, urethane coatings, anodizing and powder-coated surfaces throughout.

- Modular polycarbonate guards, accommodating many component arrangements, while allowing for pick-up.

- Packaging for shipment via motor freight.

DISCLAIMER: Product Dimensions are approximate. Shipping Dimensions and Weights are for directional use only and may change based on manufacturer variables. For the most accurate Shipping Dimensions and Weights, please contact the manufacturer.

- Product Dimensions

(L x W x H)

32" x 22" x 13" (813 x 559 x 330 mm)

160 lbs. (73 kg) - Shipping Dimensions

(L x W x H)

46" x 38" x 20" (1168 x 965 x 508 mm)

220 lbs. (100 kg)

- Recommended #903 Extended Electromechanical Workstation.

- #203-012 - Resonance and Elastic Shaft Kit

- #203-020 - Gear Fault Accessory

- #208-001 - Shaft Alignment Tool Kit

- #208-003 - Standard Shim Kit

- #208-015 - Magnetic Base/Dial Indicator Set

- #570-000 - IPT Rotating Equipment Training Manual

- #570-001 - IPT Rotating Equipment Handbook

- #203-011 - Eccentric/Cocked Rotor Kit

- #203-013 - Replacement Bent Shaft Kit

- #203-025 - Load/Brake Device Accessory, Mechanical

- #203-500 - Use/Exercise Guide (Additional)

- 115V/60Hz/1Ph power