Is the pandemic over? Some days it’s difficult to tell, as the ripple effects of continued cases of COVID-19 continue to pop up and create problems for both workers and manufacturers. Although the severity of pandemic-related disruptions has certainly subsided, industries around the world are still struggling with the aftershocks of a tumultuous few years.

In addition to ongoing supply chain woes, manufacturers are also contending with a labor marketplace that has changed fundamentally as a result of the pandemic. Prior to the pandemic, industry was struggling to fill open positions with qualified workers. Today, these struggles remain and in many areas have gotten even worse.

As a result, industries are placing a great emphasis on skills assessment to ensure that new hires can hit the ground running. In addition, upskilling current employees has taken on new significance, as industries seek to make the most of available human resources when it’s difficult to hire qualified new workers.

In this article, we’ll take a look at the current skills gap, the type of skills assessment and training that industry needs, and how the training tools offered by DAC Worldwide can help employers and instructors assess and train workers for the jobs of today and tomorrow.

How Wide is the Skills Gap?

Now that the worst of the pandemic appears to be behind us, things should be slowly getting better, right? Why then do manufacturers seem to be falling farther behind? According to an article by Alexandra Johnson:

“Before COVID, the situation was bad, but post-pandemic it has become even worse. Despite lockdown lifting, the industry is reporting over 515,000 jobs need filling, just to meet demand.”

Commonly known as the “skills gap,” there remains a sizeable disparity between the supply of highly-skilled workers and the demand for these workers in today’s industrial labor market. In fact, experts predict the skills gap is going to get even worse in the foreseeable future.

A study conducted by Deloitte for the Manufacturing Institute estimates that, over the next decade, almost 4.6 million manufacturing jobs will need to be filled. However, because of the skills gap, as many as 2.4 million — more than half! — of those jobs could go unfilled.

In a recent Forbes article, author Graham Glass notes that “[n]early half (46%) of learning and development (L&D) leaders say the skills gap is widening in their organization, and 49% say executives are concerned employees don’t have the right skills to execute business strategy, per findings from LinkedIn Learning’s ‘2022 Workplace Learning Report.’”

What is industry to do? Glass advises that “organizations need to emphasize employee upskilling, reskilling and right-skilling — and anticipate the skills employees need to succeed in their positions…By assessing the business’s needs pre-training (to develop training content) and post-training, companies can work to bridge skills gaps and create training programs that are impactful and useful to employees and the organization alike.”

Skills-Based Hiring

What’s the best approach for industry to take to bridge the skills gap? Should industry simply hire anyone they can get their hands on and then train them to do the jobs they need done? For many reasons, that strategy is probably not the best solution.

Industry is already struggling with a host of issues left over from the pandemic. Most companies don’t have the bandwidth to babysit new workers while they acquire the training they need. Many also don’t have either the personnel or the tools to effectively train new workers.

That’s why, in an article in the Harvard Business Review, LinkedIn CEO Ryan Roslansky advocates for a new skills-based approach to hiring. Roslansky urges employers to “[f]ocus on the results you’d like to see, rather than the type of qualifications that you think could deliver them. Highlighting the desired skills — the candidate’s ability to perform certain tasks — gets to the same results without creating an unnecessary barrier to entry, like a requirement for a four-year degree.”

In an article by Adina Miron, the author agrees:

“Skills-based hiring enables employers to hire for the skills gaps that exist within their organization. Rather than focusing on experience, education, or certifications, companies should focus on identifying candidates with the needed skills to fill open positions.”

Roslansky echoes these thoughts:

“Shifting to a skills-focused approach is a viable solution to an evolving workforce dilemma…Stay focused on skills — and the assessments that can measure them…there are plenty of ways to gauge a candidate’s ability to perform without relying on their education or experience as proxies.”

How do employers shift to a skills-based hiring approach? Unfortunately, generalized assessments and comprehensive training systems can be difficult to use in the context of hiring new workers in industry. Why? The answer can be found in the concept of specialization of labor.

According to an article by Sampson Quain:

“Specialization of labor…refers to a process in business in which large tasks are divided into smaller tasks, and different employees or different groups of employees complete those tasks. Specialization is highly desirable in large-scale operations such as…manufacturing because it allows workers with specific skill sets to efficiently perform a specific task.”

For example, a manufacturer may need to hire someone with a specific skillset related to the operation, maintenance, troubleshooting, and repair of mechanical belt drives. A prospective candidate might claim to have general mechanical knowledge and skills, but how can the employer know whether the worker has the specific belt drive skills it needs?

To effectively use a skills-based hiring approach in manufacturing, employers need focused assessment and training tools that can be used to adequately determine a potential worker’s skills in a very specific area.

Training at the Speed of Industry

Industry must also dedicate resources to ongoing training for current workers. The need for ongoing training is real and cannot be ignored. Industries today need to attack the skills gap with a combination of skills-based hiring and instituting training of current workers that is practical and effective.

In his Forbes article, Glass argues that “a personalized approach to training can also be useful to employees and companies.” However, he acknowledges that, “[i]n large companies, especially, creating individualized learning paths manually can be time- and resource-intensive.” He also points out that “employees need training that fits into their workflows.”

Most companies cannot afford the luxury of sending workers off-site for a week or more at a time for in-depth training. Instead, they need focused, skills-based training that allows workers to obtain the hands-on skills they need while minimizing the effect on production of time away from the workplace.

Fortunately, a variety of training tools exist that can offer industries time-saving, cost-effective solutions for focused skills assessment and hands-on training. In the next section, we’ll take a closer look at DAC Worldwide’s range of single-topic trainers that can help industry move to a skills-based hiring model and also upskill current employees.

DAC Worldwide Offers Focused Assessment & Training Tools

DAC Worldwide offers training systems for a variety of industry sectors, including advanced manufacturing, process/chemical manufacturing, marine, military, oil and gas, and power generation. These training systems also cover many different technical topics, such as electrical and electronics; heat transfer and steam; mechanical drives; oil production; process control and instrumentation; and pumps, compressors, and valves.

Rather than broad-based training in multiple areas, DAC Worldwide’s training systems provide hands-on training focused on specific tasks. This makes them particularly helpful to employers for skill assessment (either pre-employment or for upskilling purposes). For example, DAC Worldwide offers training systems targeted specifically at key mechanical maintenance skills:

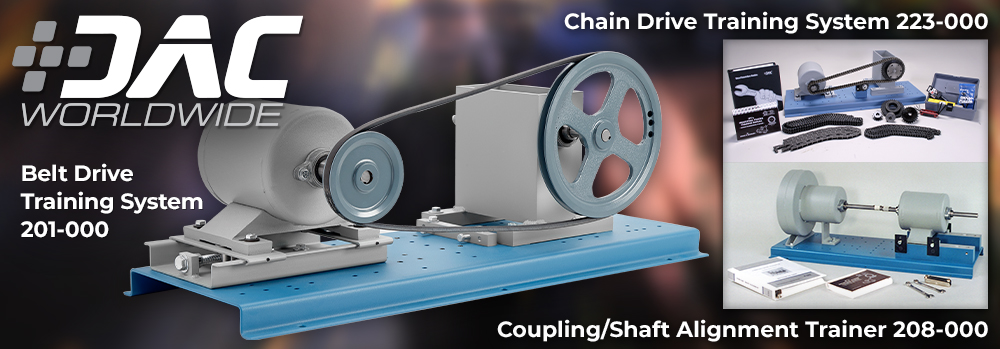

Belt Drive Training System

The Belt Drive Training System (201-000) allows for convenient assessment and training in the identification, installation, tensioning, and alignment of common belt drives types found in industry. Featuring hardware for applications related to multiple matched belts, fractional horsepower belts, positive drive belts, and variable pitch sheaves, the system provides a variety of training and assessment applications in one benchtop piece of equipment.

Coupling/Shaft Alignment Trainer

The Coupling/Shaft Alignment Trainer (208-000) allows for realistic training and assessment in shaft alignment. Designed based on the dimensions of a common ANSI centrifugal pump, this trainer can assess and train workers on all common alignment techniques and tools. Training and assessment topics include using a dial indicator in coupling/shaft alignment, the reverse dial indicator method, fabrication of shaft keys, and installing a flexible disc coupling.

Chain Drive Training System

The Chain Drive Training System (223-000) allows for in-depth assessment and training in industrial chain drives, heavy/silent chains, and sprocket set usage. Using industry-standard components workers will encounter on the job, this training system provides a complete training and assessment experience covering topics such as taper lock bushings, chain drive maintenance, installation/alignment of chains, and tensioning of chains.

Let DAC Worldwide Help You Fill Your Skills Gaps

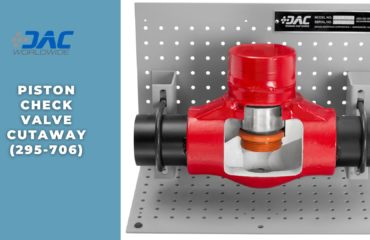

The mechanical assessment and training tools highlighted above are just a few examples of the variety of technical training tools DAC Worldwide manufactures. In addition to training systems, DAC Worldwide also offers a wide range of industrial cutaways, detailed scale models, and sample boards featuring industrial components.

Contact a consultant with DAC Worldwide today to learn more about how their technical training tools can help you build the assessment and training program your company needs. Using DAC Worldwide training and assessment tools, you can transition to a skills-based hiring approach and fill the skills gaps in your organization!

About Duane Bolin

Duane Bolin is a former curriculum developer and education specialist. He is currently a Marketing Content Developer in the technical training solutions market.