From operators and technicians to mechanics and engineers, oil and gas workers need knowledge and hands-on skills related to a wide variety of common industrial components they’ll encounter in the field. For example, a typical oil and gas worker will interact with a range of pumps and valves on a daily basis.

One such component workers will need to understand is a type of valve known as a back pressure regulator. Back pressure regulators are normally closed valves that precisely control and limit the upstream pressure in a system.

Back pressure regulators maintain a steady upstream pressure of any fluid, gas, liquid, or mixture in a system. They regulate system pressure by adjusting position, widening or narrowing to relieve or increase pressure. Usually installed at the end of a line or process, back pressure regulators ensure that all equipment used before the back pressure regulator receives the correct pressure, maintaining the integrity and effectiveness of the process.

When used in a well head, back pressure regulators control the flow of fluids or gases in the well. The back pressure regulator opens or closes with changes in the pressure of the fluid or gas, preventing overpressure within the well and protecting equipment and personnel from damage or injury. A wellhead back pressure regulator can also be used to maintain a specific pressure in a well for production or injection operations.

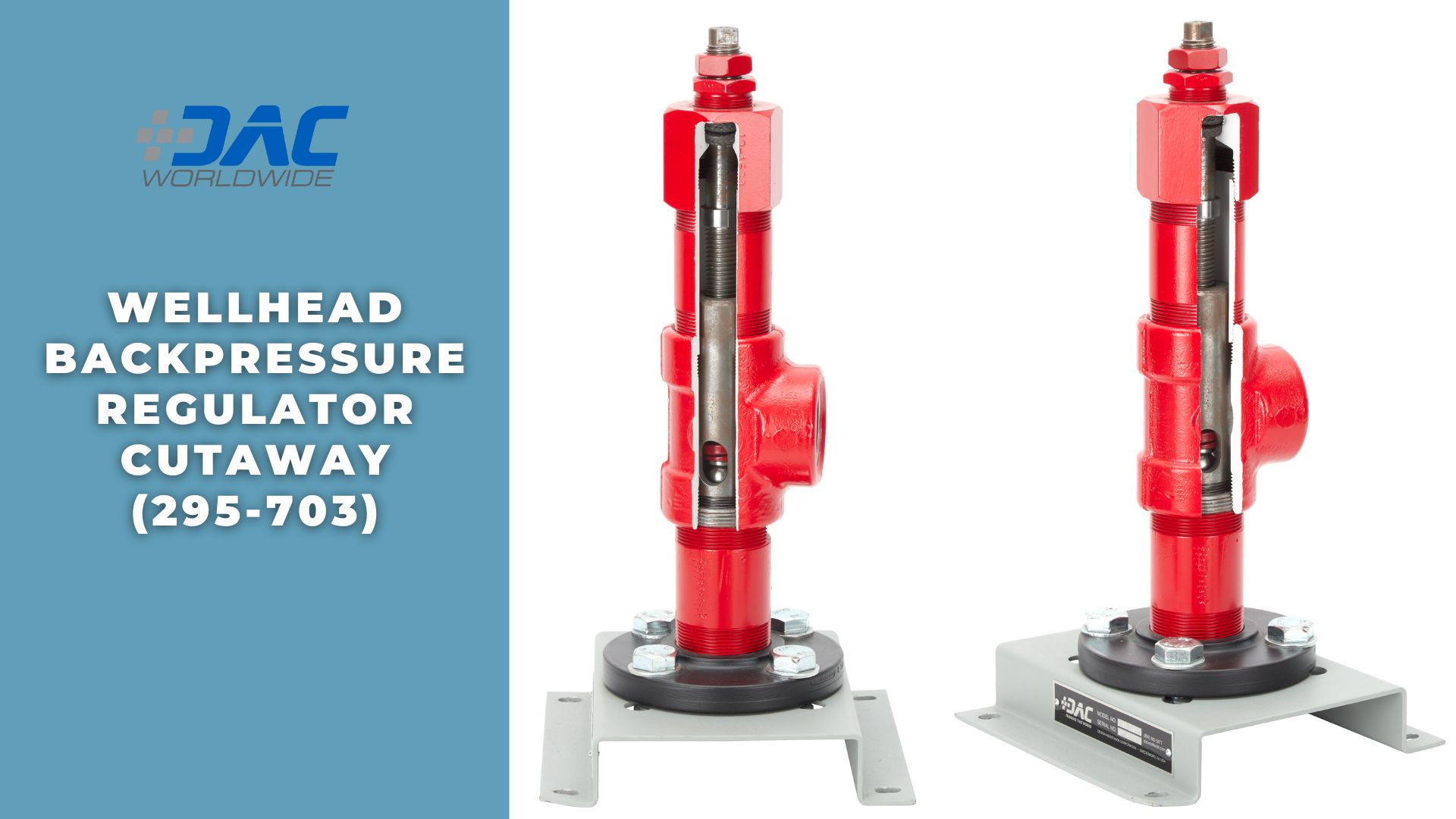

To teach oil and gas workers about these common components, DAC Worldwide’s Wellhead Backpressure Regulator Cutaway (295-703) is a sectioned specialty regulator sample that provides convenient classroom and laboratory training in the operation, construction, and maintenance of three industrial back pressure regulator (BPRs), as used in gas and oil service in the oilfield.

These common regulators are often used to maintain steady pressure on an oil column or to assure continuous flow of a producing low pressure well. They’re also regularly found in Xmas tree assemblies in the oilfield.

Through carefully planned sectioning and color-coding, the complete internal configuration of the regulating valve is exposed and showcased. Seal features and hardware locations have been retained, allowing for hands-on training in maintenance. These valves, commonly used in oil & gas production applications and commonly encountered in production wellheads and Xmas trees, are an essential part of comprehensive oil and gas production training.

The Wellhead Backpressure Regulator Cutaway is only one of DAC Worldwide’s many oil and gas training tools. Visit DAC Worldwide online to learn more about other oil and gas training aids, such as the Diaphragm Dump Valve Cutaway, Piston Check Valve Cutaway, Vertical Separator Trainer, and many more!