If the future has a color, it’s surely green. From alternative energy to renewable resources to green technology, the idea that we must reduce, reuse, and recycle is far from a new one. However, it’s not always about abandoning the way we’ve always done things. Sometimes it’s a matter of combining the old with the new.

According to a recent Interesting Engineering article by Mrigakshi Dixit, “Phoenix Tailings, a company founded by MIT alumni…is developing a method to recover rare earth metals and nickel from mining waste.”

The Woburn, Massachusetts, company discovered that “[r]are earth elements, essential for the magnets in wind turbines and electric vehicles…are often locked away in mining waste.” While China currently leads the world in production of these high-demand elements, Phoenix Tailings believes it can become a significant source of these elements in the near future.

“Their innovative process uses water and recyclable solvents to extract rare earth metals from mining waste. The metals are then purified using a unique electrochemical process that’s both efficient and environmentally friendly.”

The company’s process “eliminates toxic byproducts and reduces carbon emissions, making it a sustainable solution for the future.” The company believes it can “produce over 3,000 tons of these critical metals by 2026.”

Phoenix Tailings expects to supply “customers with several rare earth elements, including neodymium and dysprosium, which are crucial components in magnet production.” With the help of “over $2 million from the U.S. Department of Energy,” the company’s materials will benefit a variety of industries, including “wind energy, electric vehicles, and defense technology.”

Fortunately, the company’s “process can handle various ore types and mining waste. Moreover, the company has access to abundant resources as the U.S. mining industry generates approximately 1.8 billion tons of waste each year.”

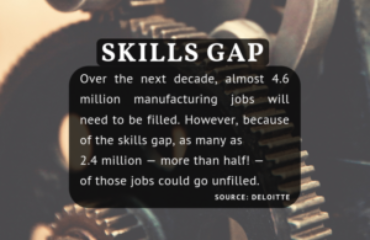

As Phoneix Tailings expands and other companies mimic their processes, there is great potential for growth in turning mining waste into valuable rare earth elements needed for the technologies driving the future. What these companies will need more of is a supply of skilled workers to fill open positions as expansion takes place. That’s why DAC Worldwide offers a variety of hands-on training tools designed to teach the industrial skills workers need in the modern workplace. For example, be sure to check out DAC Worldwide’s Process Control and Instrumentation training tools and contact a DAC Worldwide representative to learn how you can improve your training today!