5 Tools You Need in Your Industrial Training Toolbox

Click HERE to view this article as a multimedia presentation.

With the national economy chugging along steadily and unemployment rates remaining at their lowest levels in decades, it’s easy for most people to forget that industries across the board are facing a workforce crisis that’s destined to get worse before it gets better. Industrial training programs are an important part of the solution. Do you have all the tools you need in your industrial training toolbox?

The Skills Gap

Commonly known as the “skills gap,” there’s a sizeable disparity between the supply of highly-skilled workers and the demand for these workers in today’s industrial labor market. According to a recent Bureau of Labor Statistics Job Openings and Labor Turnover Survey, there were 522,000 open manufacturing jobs in the United States as of July 2019.

Experts predict the skills gap is going to get even worse in the foreseeable future. A study conducted by Deloitte for the Manufacturing Institute estimates that, over the next decade, almost 4.6 million manufacturing jobs will need to be filled. However, because of the skills gap, as many as 2.4 million — more than half! — of those jobs could go unfilled.

Industries cannot wait for educational institutions to fill the pipeline of highly-skilled workers. That’s why many industries have recognized the need to upskill incumbent workers to perform advanced operations and maintenance tasks.

Modern industrial training requires a multifaceted approach. One size no longer fits all when it comes to relevant, quality industrial training. DAC Worldwide offers a unique combination of training tools that can increase the effectiveness and efficiency of any industrial training program, including training systems, cutaways, dissectibles, sample boards, and models.

Training Systems

DAC Worldwide offers training systems for a variety of industry sectors, including advanced manufacturing, process/chemical manufacturing, marine, military, oil and gas, and power generation. These training systems also cover many different technical topics, such as electrical and electronics; heat transfer and steam; mechanical drives; oil production; process control and instrumentation; and pumps, compressors, and valves.

Rather than broad-based training in multiple areas, DAC Worldwide’s training systems provide hands-on training focused on specific tasks. This makes them particularly helpful to employers for skill assessment (either pre-employment or for upskilling purposes).

For example, DAC Worldwide’s Lock-Out/Tag-Out Training System (811-000) features a realistic, simulated working process environment that provides training with hands-on activities related to the process of identifying and locking out sources of dangerous potential energy in an industrial setting.

Click on the link below to view an animation of the Lock-Out/Tag-Out Training System:

Cutaways

DAC Worldwide’s industrial component cutaways provide hands-on experience with real, industrial components that have been professionally sectioned to expose key internal components to help learners understand how they work. Cutaways possess a unique “wow” factor guaranteed to capture learners’ interest.

DAC Worldwide’s industrial component cutaways provide hands-on experience with real, industrial components that have been professionally sectioned to expose key internal components to help learners understand how they work. Cutaways possess a unique “wow” factor guaranteed to capture learners’ interest.

Many of DAC Worldwide’s large selection of cutaways retain functionality, and an attached hand wheel allows learners to observe low-speed manual operation. For industrial training relevance, common models by well-known manufacturers are chosen when manufacturing cutaways.

For example, DAC Worldwide’s Right-Angle Worm Gear Reducer Cutaway (205-201) is a sectioned industrial gear reducer that will complement mechanical drives training by allowing learners to see inside the component housing to learn how the gear reducer works.

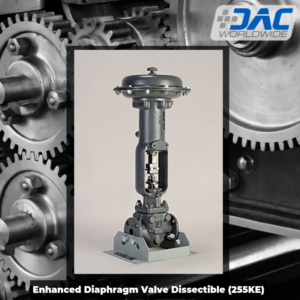

Dissectibles

DAC Worldwide’s dissectibles take cutaways to the next level by allowing learners to disassemble and reassemble real industrial components. There’s simply no better way to train someone on the maintenance of a particular component than letting them disassemble and reassemble an actual unit.

DAC Worldwide’s dissectibles take cutaways to the next level by allowing learners to disassemble and reassemble real industrial components. There’s simply no better way to train someone on the maintenance of a particular component than letting them disassemble and reassemble an actual unit.

Moreover, dissectibles provide valuable hands-on training that gives unique insight into and experience with components without damaging or occupying other training equipment. You don’t need to take risks with expensive equipment when learners can work with a dissectible instead.

For example, DAC Worldwide’s Enhanced Diaphragm Valve Dissectible (255KE) is a hands-on valve sample that offers realistic classroom training in the disassembly, inspection, and reassembly of a full-size industrial diaphragm-actuated control valve used throughout industry.

Click on the link below to view an animation of the Enhanced Diaphragm Valve Dissectible:

Sample Boards

DAC Worldwide’s sample boards offer valuable maintenance training in the identification and selection of a variety of industrial components. Each sample board features a selection of real industrial components mounted with nameplates for easy association with individual components.

DAC Worldwide’s sample boards offer valuable maintenance training in the identification and selection of a variety of industrial components. Each sample board features a selection of real industrial components mounted with nameplates for easy association with individual components.

Sample boards expand learners’ knowledge through exposure to multiple varieties of industrial components. Available sample boards include components like mechanical fasteners, belts, chains, couplings, gears, and bearings.

For example, DAC Worldwide’s Coupling Sample Board (839-PAC) is a hands-on teaching aid designed to supplement courses in coupling selection and maintenance. It includes samples of eight industrial-quality couplings for users to learn to identify.

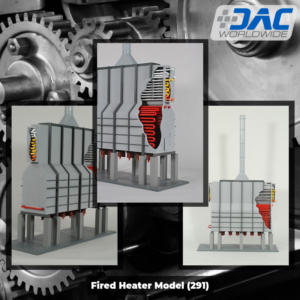

Models

DAC Worldwide also offers an array of incredibly-detailed, intricately-crafted models. These life-like scale models depict various industrial machines across numerous sectors and include all primary features and components.

DAC Worldwide also offers an array of incredibly-detailed, intricately-crafted models. These life-like scale models depict various industrial machines across numerous sectors and include all primary features and components.

Sometimes industrial training tends to focus so intently on the details that learners can’t see the forest for the trees. Models allow students to learn how the parts of a system work together on a small, easily-managed model without the need for a field trip to an industrial site.

For example, DAC Worldwide’s Fired Heater Model (291) depicts a common industrial furnace found in refineries and process facilities throughout industry. It allows learners to explore the operation and maintenance of a cabin-type box heater with twin fireboxes and realistic support piers, burners, access openings, stack dampers, and many more industrial-grade component replicas.

Explore DAC Worldwide’s Unique Training Solutions

If your industrial training toolbox doesn’t include a combination of training systems, cutaways, dissectibles, sample boards, and models, contact a DAC Worldwide representative to learn more about how you can use these unique training tools to assemble complete training courses or supplement existing training programs.

You can also connect with DAC Worldwide via its social media channels, including YouTube, Instagram, LinkedIn, Twitter, and Facebook.

- Published in News