DAC Worldwide Makes Industrial Maintenance Training Easy!

Industrial maintenance training for technicians in the oil and gas and petrochemical industries must teach them fundamental knowledge of and hands-on skills related to a wide variety of different types of valves that keep fluids flowing through vast networks of piping.

For example, different types of check valves help to prevent the reversal of fluid flow in piping systems. One specific check valve — the piston check valve — can often be found in systems that experience frequent changes in fluid flow direction.

Maintenance technicians will find piston check valves in all sorts of common applications, including: water, steam, and air systems; feed water control in nuclear facilities and steam power generation plants; freshwater supply; wastewater treatment; monitoring and sampling systems; dump lines; food and beverage processing; air conditioning systems; and pharmaceuticals and chemicals manufacturing.

Piston check valves contain a dash-pot with a cylinder and weighted piston or disc. These valves are activated by fluid flowing through a system. The pressure of the flowing fluid opens the valve, which allows unobstructed flow in one direction while fluid flow pressure remains constant.

When pressure decreases as fluid flow slows or reverses, gravity forces the piston to close the valve, preventing backflow. While piston check valves primarily rely upon gravity, the weight of the piston, and back pressure to force closure of the valve, some models also incorporate springs to assist with valve closure.

Piston check valves are popular because of their many advantages, including: durability; versatility; repairability; cost-effectiveness; efficiency; and ease of installation, maintenance, and repair. However, piston check valves are not suitable for applications requiring bi-directional fluid flow or pulsation fluid flow.

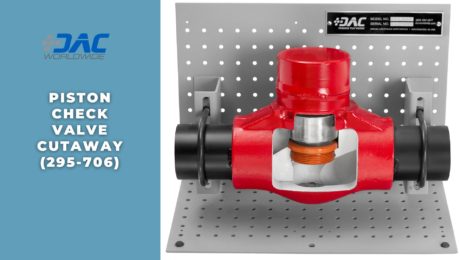

If you want to ensure your maintenance technicians have the skills to work with piston check valves, DAC Worldwide’s Piston Check Valve Cutaway (295-706) provides valuable classroom training in the operation, construction, and maintenance of industrial piston-type check valves.

DAC Worldwide’s valve cutaways use actual industrial valves that have been carefully sectioned and color-coded to expose and showcase the complete internal configuration of the valve. Seal features and hardware locations are retained, allowing for “hands-on” training in maintenance.

Moreover, common valve makes and models are chosen to ensure industrial relevancy. All cleaning, priming, and painting uses a high-durability urethane coating to ensure this training tool will last for years.

DAC Worldwide’s Piston Check Valve Cutaway features a welded-bonnet, socket-welded valve exactly like those commonly used in high pressure oil & gas production applications, providing unparalleled training to those involved in oil & gas production operations and maintenance training.

The Piston Check Valve Cutaway is only one of DAC Worldwide’s many oil and gas training cutaways. Visit DAC Worldwide online to learn more about other oil and gas training tools, such as the Diaphragm Dump Valve Cutaway, Oilfield Backpressure Regulator Cutaway, and many more!

- Published in News