Data-Driven Maintenance Leads to Continuous Improvement

What’s the most-feared word in the manufacturing sector? While there certainly are a wide variety of candidates, we’d be willing to bet that “downtime” is quite high on the list. No manufacturer likes to hear that critical machinery is down, leading to production delays and potentially expensive repair costs.

When looking for ways to boost productivity and efficiency, many manufacturers analyze downtime statistics to try to figure out what’s causing downtime and how to minimize it. Is a particular machine to blame? Are machines not being maintained in a timely manner? Is equipment not being utilized appropriately?

Unfortunately, too many manufacturers have nothing to analyze other than miscellaneous reports by maintenance managers. That’s why rubber compounding manufacturer Hexpol Compounding America (HCA) recently invested in a computerized maintenance management system (CMMS).

According to a recent IndustryWeek article by Dennis Scimeca, maintenance at HCA was “not a focus at the executive level.” However, after implementation of a CMMS, leadership realized that the CMMS could “lay the groundwork for a new, company-wide total preventative maintenance (TPM) initiative” that “ties directly into…HCA’s corporate strategy plan[, which] includes continuous improvement and lean management goals.”

For example, the CMMS allowed HCA to take “a data-rich approach to boost equipment availability and found continuous improvement opportunities throughout all of its operations.” One focus was on inventory reduction, keeping track of “parts inventories and repairs to determine how shelf-life relates to replacement-part needs.”

The CMMS provided some interesting insights: “O-rings don’t last forever. If you sit on a part for 10 years, if it has rubber seals in it, it’s probably bad. We probably shouldn’t be holding on to that because it’s a cost. If we’re relying on that part to work in 10 years and it fails right away, it did us no good to even hold that part.”

Likewise, “[i]f they sit too long, the bearings in large motors flatten because of the weight. Something as simple as rotating a shaft a quarter turn once a month prevents those motors from becoming write-offs and incurring replacement costs. The CMMS determines the best PM schedules to avoid the motors from failing.”

HCA’s maintenance leaders have been pleased with how the CMMS has helped them use real data to drive changes. According to HCA’s CEO, “We’re only doing the things that we know we can control and that are actually going to give us the benefits we need.” And how do they know it’s working? “[T]he CMMS provides real truth on whether the new policies deliver results or not.”

The data provided by the CMMS has also helped HCA leaders to work more closely together. Quarterly one-on-one meetings with site leaders “make sure larger goals meet the specific needs of individual plants and that everyone has the resources they need…A good example is trying to find maintenance technicians. If we have three openings at a site and not seeming like we’re getting any resumes for interviews I can try to go to HR and figure out what’s going on. What do we need to do to get this done?”

Speaking of maintenance technicians, it’s no surprise that HCA’s multiple locations would still need to hire highly skilled maintenance technicians. The CMMS didn’t reduce the need for ongoing reactive and proactive maintenance. To the contrary, it provided data to support the importance of maintaining equipment on a regular basis to optimize efficiency and productivity.

For companies like HCA, that means hiring new maintenance technicians with the skills they need to succeed, as well as upskilling current maintenance workers to ensure they’re up to the task of tackling the maintenance priorities the CMMS highlights. For many companies, this will mean making investments in things like ongoing training, in addition to new technology, like a CMMS.

For companies looking to set up or improve their maintenance training, a thorough review of current training materials is a great place to start. Do employees have access to hands-on training with actual components they’ll encounter on the job? If not, partnering with established companies to provide industrial-quality training systems that will stand the test of time will help ensure the productivity of the workforce.

For example, DAC Worldwide offers a wide variety of training systems specifically designed to give employees the hands-on experience they need to master essential industrial maintenance skills. Be sure to check out DAC Worldwide’s advanced manufacturing training systems and contact a DAC Worldwide representative to learn how you can improve your training today!

- Published in News

DAC Worldwide Makes Industrial Maintenance Training Easy!

Industrial maintenance training for technicians in the oil and gas and petrochemical industries must teach them fundamental knowledge of and hands-on skills related to a wide variety of different types of valves that keep fluids flowing through vast networks of piping.

For example, different types of check valves help to prevent the reversal of fluid flow in piping systems. One specific check valve — the piston check valve — can often be found in systems that experience frequent changes in fluid flow direction.

Maintenance technicians will find piston check valves in all sorts of common applications, including: water, steam, and air systems; feed water control in nuclear facilities and steam power generation plants; freshwater supply; wastewater treatment; monitoring and sampling systems; dump lines; food and beverage processing; air conditioning systems; and pharmaceuticals and chemicals manufacturing.

Piston check valves contain a dash-pot with a cylinder and weighted piston or disc. These valves are activated by fluid flowing through a system. The pressure of the flowing fluid opens the valve, which allows unobstructed flow in one direction while fluid flow pressure remains constant.

When pressure decreases as fluid flow slows or reverses, gravity forces the piston to close the valve, preventing backflow. While piston check valves primarily rely upon gravity, the weight of the piston, and back pressure to force closure of the valve, some models also incorporate springs to assist with valve closure.

Piston check valves are popular because of their many advantages, including: durability; versatility; repairability; cost-effectiveness; efficiency; and ease of installation, maintenance, and repair. However, piston check valves are not suitable for applications requiring bi-directional fluid flow or pulsation fluid flow.

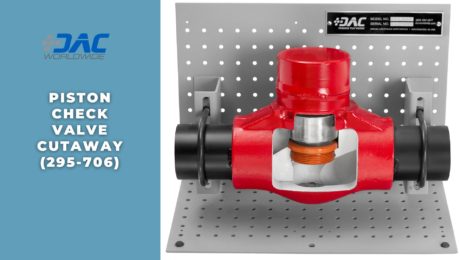

If you want to ensure your maintenance technicians have the skills to work with piston check valves, DAC Worldwide’s Piston Check Valve Cutaway (295-706) provides valuable classroom training in the operation, construction, and maintenance of industrial piston-type check valves.

DAC Worldwide’s valve cutaways use actual industrial valves that have been carefully sectioned and color-coded to expose and showcase the complete internal configuration of the valve. Seal features and hardware locations are retained, allowing for “hands-on” training in maintenance.

Moreover, common valve makes and models are chosen to ensure industrial relevancy. All cleaning, priming, and painting uses a high-durability urethane coating to ensure this training tool will last for years.

DAC Worldwide’s Piston Check Valve Cutaway features a welded-bonnet, socket-welded valve exactly like those commonly used in high pressure oil & gas production applications, providing unparalleled training to those involved in oil & gas production operations and maintenance training.

The Piston Check Valve Cutaway is only one of DAC Worldwide’s many oil and gas training cutaways. Visit DAC Worldwide online to learn more about other oil and gas training tools, such as the Diaphragm Dump Valve Cutaway, Oilfield Backpressure Regulator Cutaway, and many more!

- Published in News