Do you live in an area that has experienced some of the sweltering heat waves that have plagued the United States the last several years? While scientists and politicians may squabble over the causes of and solutions to the record temperatures we’re seeing, it’s a simple fact that the last few years have been some of the hottest on record.

While increasing global temperatures present a whole host of problems, there’s one industry that’s staying busier than ever when the heat is on. That’s right. We’re talking about the heating, ventilation, air conditioning, and refrigeration industry, more commonly referred to as HVACR.

HVACR professionals, from installers to technicians, keep the machines that make our lives comfortable and enjoyable running smoothly. From the central air conditioning unit that keeps your home cool to the industrial refrigeration units that chill your foods and beverages at the local grocery and convenience store, it’s hard to imagine modern life without the convenience of a wide variety of HVACR equipment.

Unfortunately, the HVACR industry is dealing with the same shortage of highly-skilled workers that manufacturing and dozens of other industries across the country have been facing for years. There simply aren’t enough qualified workers to fill the open positions available in the HVACR industry.

That’s why highly-skilled HVACR technicians are in such great demand these days. Today’s HVACR technicians need expertise with a wide variety of common HVACR components. For example, when dealing with large air conditioning systems or commercial refrigeration units, in-depth knowledge of and experience with compressors is essential.

Some of these systems may feature hermetic compressors, which seal both the motor and compressor inside a leak-proof welded steel shell. Unfortunately, this design makes basic repairs impossible. If the unit fails, it must simply be replaced.

That’s why the design of semi-hermetic compressors has become a popular choice for these systems today. Semi-hermetic compressors also protect the motor and compressor inside a sealed shell. However, unlike hermetic compressors, semi-hermetic compressors can be opened to provide access to many essential mechanical parts, so that they can be maintained and repaired rather than replaced.

Performing routine maintenance on semi-hermetic compressors can extend their service life by many years, saving thousands of dollars. With proper care and maintenance, semi-hermetic compressors can perform at peak efficiency for 8-10 years or more.

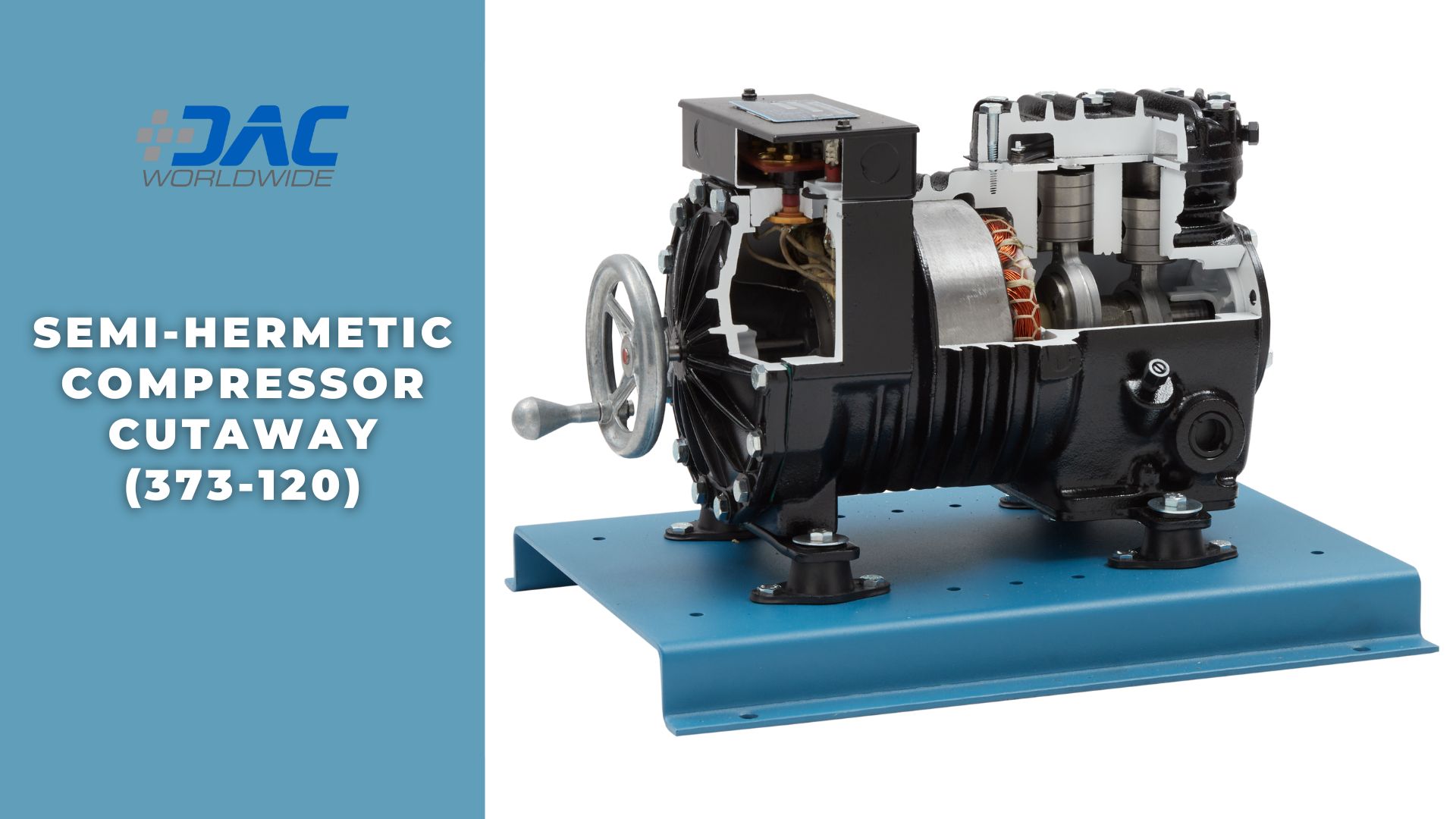

If you want to teach an aspiring HVACR technician how to maintain and repair a semi-hermetic compressor, DAC Worldwide’s Semi-Hermetic Compressor Cutaway (373-120) is an expertly-sectioned example of a common intermediate (1”-1 ½”) horsepower semi-hermetic refrigeration compressor that facilitates and supports practical training in compressor design, operating principles, and maintenance.

This unique training tool features a full longitudinal cutaway of a semi-hermetic compressor, which allows for full visibility of the compressor’s operating components, including multiple cylinders, valves, internal motor, and crank shaft. Multiple cutaways unveil all internal components, and cutaway surfaces are enhanced through painting, making the geometry of all components more clear.

The Semi-Hermetic Compressor Cutaway is only one of DAC Worldwide’s many HVACR training cutaways. Visit DAC Worldwide online to learn more about other HVACR training tools, such as the Hermetic Scroll Refrigeration Compressor Cutaway, the Open Drive Refrigeration Compressor Cutaway, the ACR Solenoid Valve Cutaway, and more!