Industrial maintenance technicians must be familiar with a wide variety of valves used throughout many different types of industries. A common task technicians will encounter on the job is replacing valve packing to prevent valves from leaking.

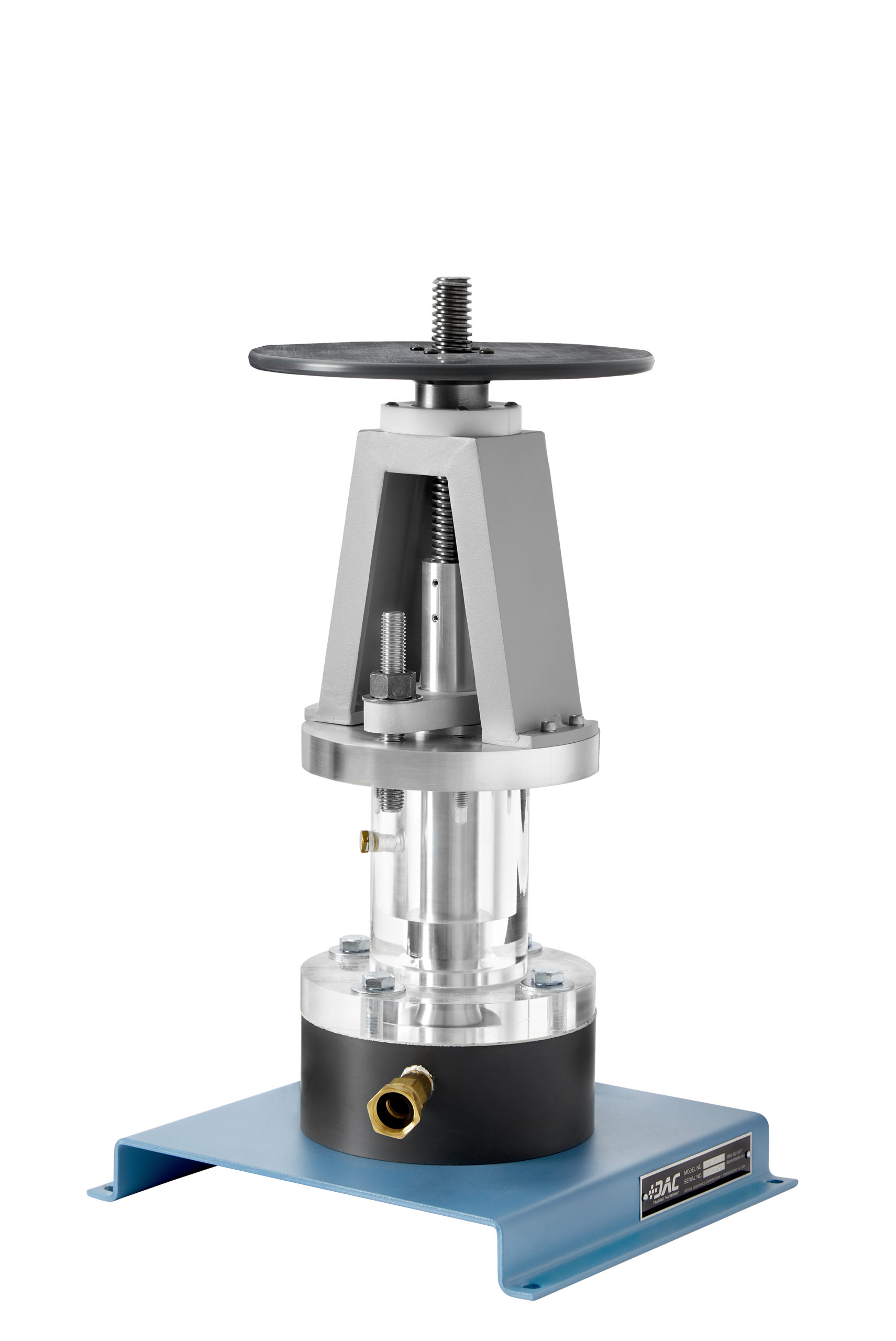

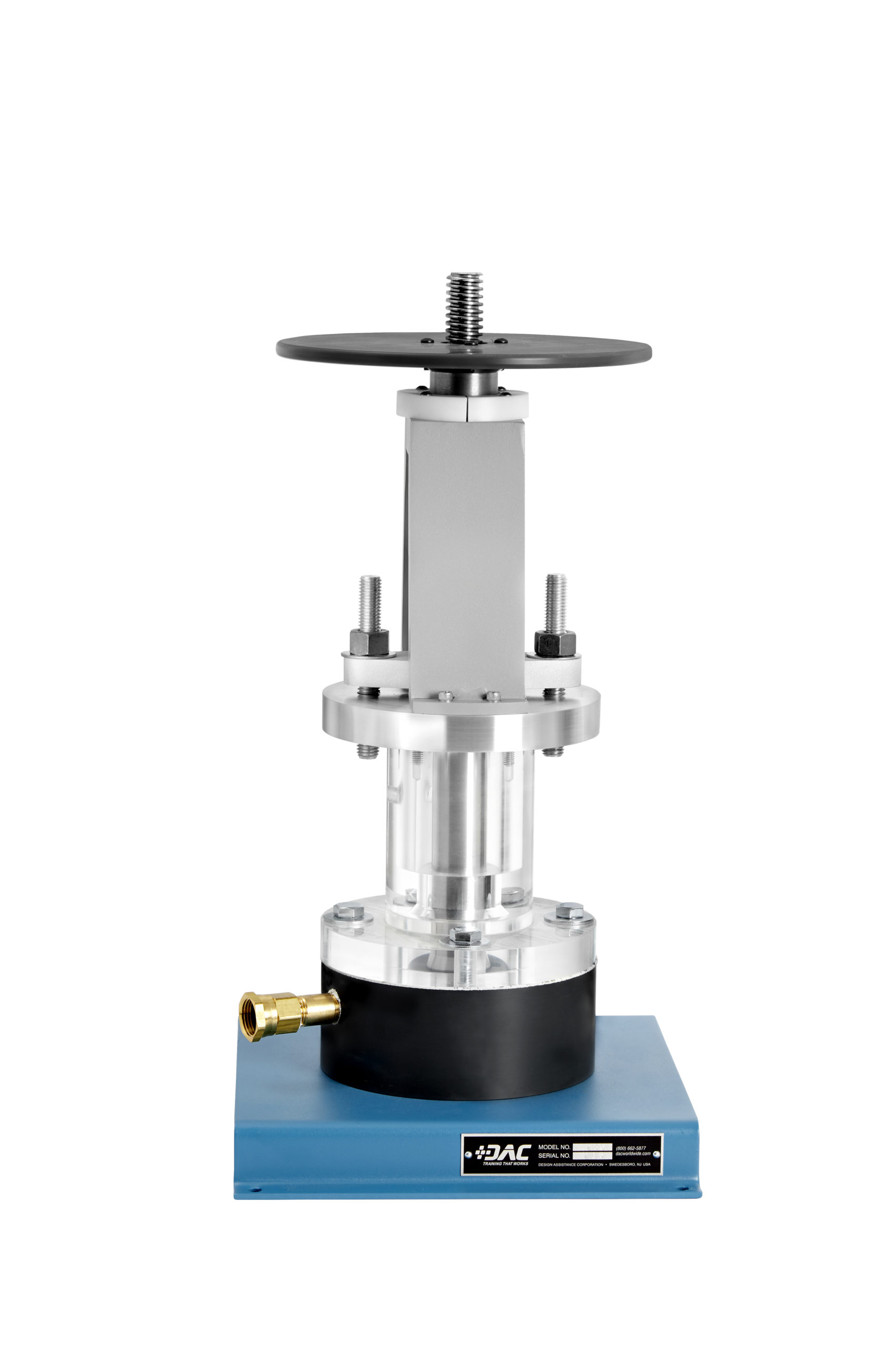

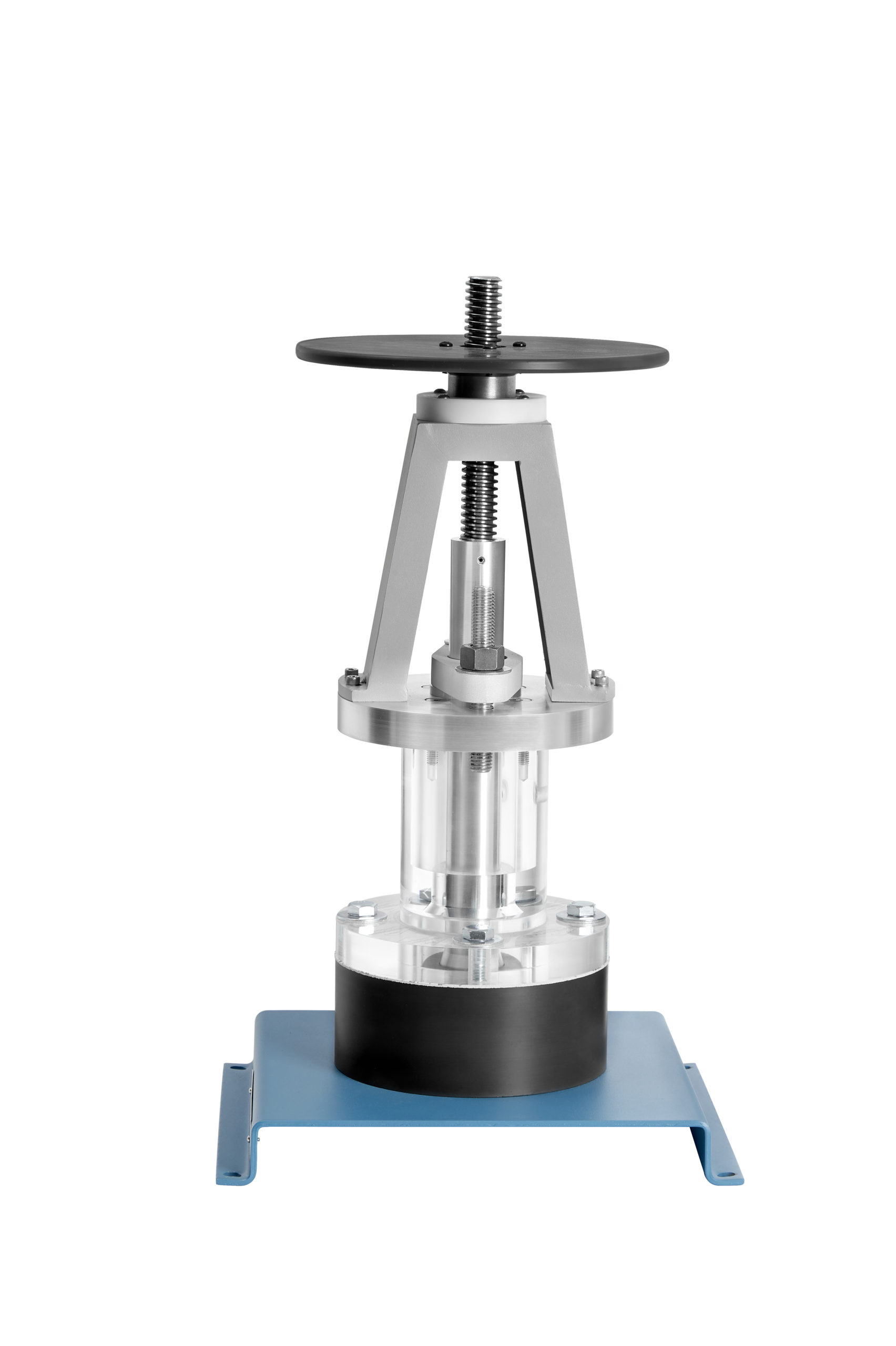

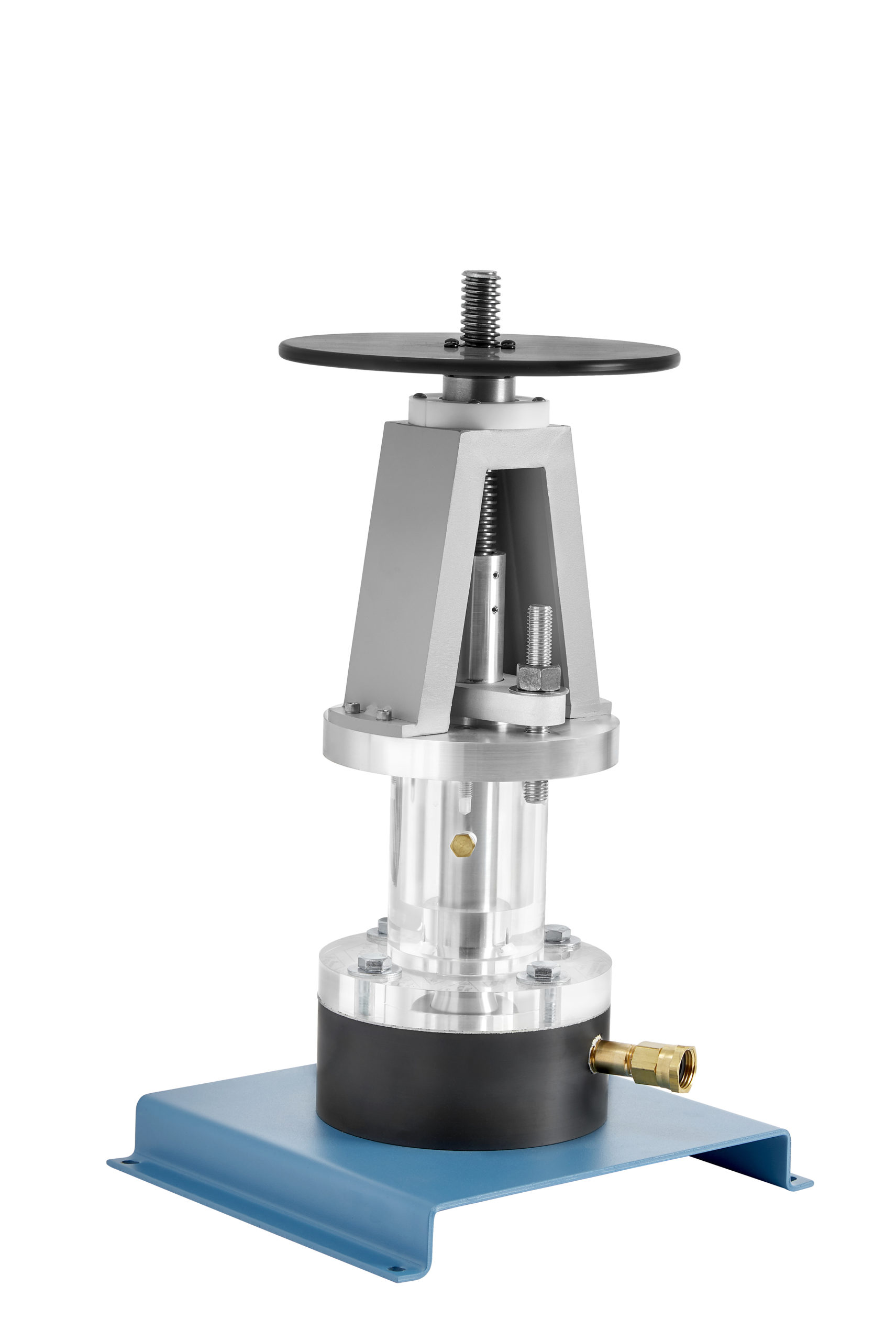

DAC Worldwide’s Valve Packing Training System (250-PAC) features a detailed replica of a 6-inch gate valve with backseat to train learners in the proper removal and installation of valve packing. The system allows for convenient demonstration of live-loaded packing and the use of die-formed graphite packing, as well as conventional packing materials.

The 250-PAC includes the following items:

- #250 - Valve Packing Training System

- #250-001 - Additional Packing Set

- #250-002 - Bulk Braided Packing

- #250-010 - "One Piece" Gland

- #250-011 - Standard Split Spacer for Standard Packing

The system’s design includes a clear acrylic stuffing box that provides total visibility of the packing area during both maintenance activities and after compression. The natural magnification created by the acrylic housing clearly shows consolidation and packing pressure against the cavity wall. Water and coloring can also be introduced to see migration due to insufficient gland load, improper installation techniques, and stem/cavity imperfections.

Industry-Standard Components Provide Realistic, Hands-On Training

Technical training is most effective when learners can gain hands-on practice with industry-standard components they’ll encounter on the job. The Valve Packing Training System features a variety of common, industrial-quality components to provide learners with a realistic training experience that will build skills that translate easily to the workplace.

The Valve Packing Training System is a sturdy unit patterned after a 6-inch, 600-pound Anchor/Darling pressure seal gate valve with backseat. Some of the industrial-quality components learners will find on the system include: clear acrylic "bonnet" with 2.250-inch diameter x 5.125-inch deep packing chamber; aluminum simulated valve body and yoke assembly; 1.5-inch diameter aluminum working stem machined to 32 RMS with 2-inch travel; ¾-inch "NH" (hose) drain and lantern ring bleed-off connections; aluminum gland and follower; nylon backseat; and aluminum lantern ring.

The system comes mounted on a 7-gauge, formed-steel baseplate with provision for tabletop mounting. A variety of other standard accessories come with the system, including: inspection mirror; standard set of PTFE type, 3/8-inch, braided, non-asbestos packing; two 10-inch long packing pullers; two 10-inch long lantern ring pullers; 6-inch pocket depth scale; 20 tablets non-toxic coloring; two standard Garlock gaskets; 1.5-inch diameter x 12-inch long PVC cutting mandrel for packing ring fabrication; Crocus cloth; packing pusher/driver; six pairs of plastic disposable gloves; and a plastic tool box.

Courseware & Hands-On Exercises

The Valve Packing Training System’s courseware consists of a course guide on valve packing and a set of illustrated hands-on exercises. These can be used as part of either an instructor-led course or self-directed study.

Hands-on exercises include industry-relevant valve packing skills, such as: performing valve component inspections; packing a valve with compression packing and lantern ring; repacking a valve using braided packing and a stuffing box spacer; repacking a valve with a die-formed packing set; and retrofitting a valve with a live loading valve stem gland assembly.