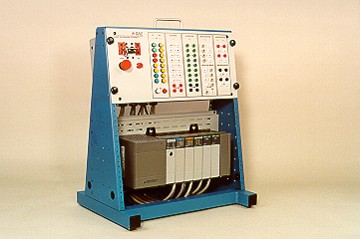

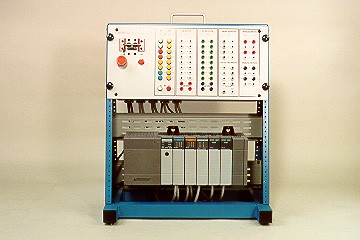

- Steel mounting frame, 16-gauge

- Provision for mounting PLC of choice via mounting brackets and/or DIN rail

- Welded tubular aluminum base assembly with rubber feet

- Steel electrical enclosure, 16-gauge

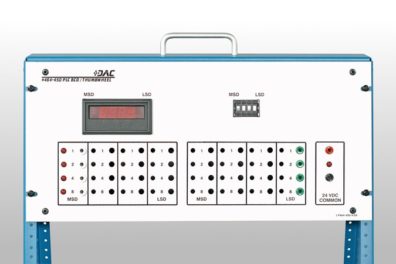

- Silk-screened 19" rack-mount panel face with safety interlock

- All steel and aluminum components powder coated for durability

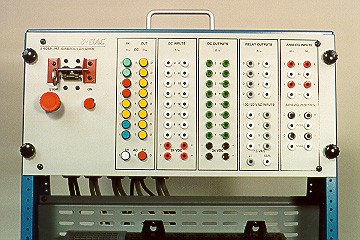

- Circuit breaker with provision for lock-out/tag-out

- Pilot light and safety switch

- Instructor key switch (rear of enclosure)

- Internal, supplemental 24VDC power supply

- Eight (8) DC, lighted, input switches, including normally open, normally closed, momentary and latching varieties

- Eight (8) DC output lights

- One (1) AC, lighted, input switch

- One (1) AC output light

- Provision for connection to external applications via banana jacks including: - 16 DC inputs. - 16 DC outputs. - Four (4) AC inputs. - Four (4) AC outputs. - Four (4) analog inputs. - Four (4) analog outputs. - Connections for 24VDC and 110VAC power

- Tagged, 16-lead, cables for connection to user-supplied or optional PLC hardware

- Wiring diagram for use with an Allen-Bradley, SLC-500

- Provision for mounting on related bench and workstation products

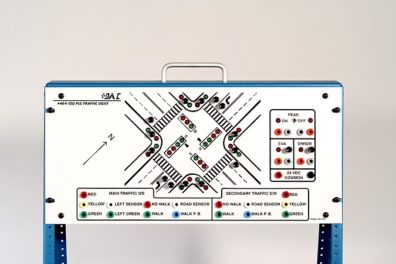

- Allows for connection to training products relating to process control, motors/motor control, sensors, PLC applications and fluid power

- Crating for shipment via motor freight

- Circuit Breaker

- Pilot Light with Safety Switch

- Instructor Key Switch

- Power Supply

- Eight (8) DC Input Switches

- Eight (8) DC Output Lights

- One (1) AC Input Switch

- One (1) AC Output Light

- #464-5000 - Basic PLC Use/Exercise Guide

The courseware, useful in both a instructor-led and or a self-directed format, includes one of several optional textbooks, a course guide and hands-on exercises.

Exercises include:

PLC Basic Information

- Introduction to PLC

- PLC Internal Operations

- Series and Parallel Circuits

- Numbering Systems

- Boolean Algebra

- Ladder Logic

SLC 500 Basic Information

- SLC 500 Trainer Familiarization

- Introduction to SLC 500 Programming

- External Input and Output Elements

- Internal Bits

- AND, OR and NOT Gates

- Latching Instructions

- Timers

- Counters

- Cascading Timers

- Move and Convert Instructions

- EQU, NEQ, LES, and GRT Instructions

- LEQ and GEQ Instructions

SLC 500 Basic Applications

- Coolant System Application

- Conveyor Application

- Batch Processing Application

- Test Station Application

SLC 500 Advance Instructions

- Arithmetic Instructions

- JMP, LBL and MCR Instructions

- Jump to Sub-routine Instructions

- Bit Shift and File Copy Instructions

- Sequencer instructions

SLC 500 Advanced Applications

- Palletizer Application

- Candy Bar Production Line App.

- Automated Paint Booth App.

- Pick and Place Robot App.

Glossary

- Programming Instructions Interfacing with External Devices

DISCLAIMER: Product Dimensions are approximate. Shipping Dimensions and Weights are for directional use only and may change based on manufacturer variables. For the most accurate Shipping Dimensions and Weights, please contact the manufacturer.

- Product Dimensions

(L x W x H)

14" x 20" x 23" (350 x 500 x 580 mm)

42 lbs. (19 kg) - Shipping Dimensions

70 lbs. (32 kg)

- 100-240V/50-60Hz/1ph