Many different types of manufacturing processes depend upon the carefully-controlled movement of fluids, such as liquids and gases, through a complex system. That’s why process control and instrumentation are vital parts of many major industries, including: power generation; petrochemicals; food processing and bottling; chemical manufacturing; biotechnology; pharmaceuticals; refineries; and more.

For example, a recent IndustryWeek article by Gerry Abbey and Lance Heinen details the “journey to embrace smart manufacturing technology” made by “Texas’s largest pickle manufacturer,” Best Maid Pickles. “Founded in 1926, Best Maid Pickles” sought to improve productivity and efficiency as the organization continued to expand its operations.

The authors note that, “[a]cross the food and beverage industry, the adoption of smart manufacturing technologies, while extremely desirable, has been slowed by concerns around cost, lack of knowledge and lack of skills.” However, with proper research and strategic implementation, these technologies can transform a business.

Best Maid Pickles stands as a perfect example of such transformation. As the authors conclude, “the Best Maid Pickles journey illustrates how embracing smart manufacturing technology can drive efficiency, productivity and profitability…The implementation delivered a significant ROI through reduced costs and increased revenue, empowering Best Maid for sustained growth and success.”

The authors believe that, “[b]y leveraging technology, companies can position themselves for a thriving future in the ever-evolving manufacturing landscape.” The journey will not be without its challenges, however, and those must be anticipated and tackled head-on.

One common challenge when implementing new advanced automation technologies is the need for highly skilled workers to operate, maintain, troubleshoot, and repair these new systems. Whether a company decides to search for new employees with the skills they need or train current employees to equip them with necessary skills, employers must focus on ensuring workers possess the hands-on process control and instrumentation skills they require.

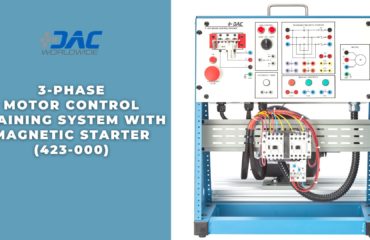

Fortunately, employers don’t have to reinvent the wheel when it comes to effective process control and instrumentation training. Partnering with a training solutions provider with a proven track record can help any manufacturer or educational institution train workers with the hands-on skills they’ll need to hit the ground running in the workplace.

For example, DAC Worldwide offers a wide variety of training systems that teach basic to advanced process control and instrumentation skills. Its newest flagship process control and instrumentation trainer, the Smart Process Plant Training System (603-SP), is a fully-functional, industrial-quality fluid process system that provides hands-on training in the measurement and control of five of the most common process variables: level, pressure, temperature, flow, and pH.

The system groups these process control elements into one complete piping system, which allows it to teach multiple configurations of flow loops, controls, and communications. The system incorporates both new and legacy technologies so that users are prepared for anything they might encounter on the job. These technologies work together to form a 3-level communication architecture:

- Device Level: Smart sensors monitor Level, Flow, Temperature, Pressure, and pH. They are connected via either IO-Link and Ethernet communication or HART communication.

- Control Level: A DCS and various PLCs and PIDs allow for operation and control of the system’s components.

- Enterprise Level: The DCS software provides Supervisory Control with data analytics for monitoring smart production, smart maintenance, etc.

The Smart Process Plant uses a Distributed Control System (DCS) that features Supervisory Control software. This software is Rockwell Automation’s PlantPAx, and it acts as the backbone of the system. It gathers and organizes data and creates dashboards that represent the real-time status of the processes being carried out by the system.

The Smart Process Plant Training System features a wide variety of common, industrial-quality components and instruments to provide learners with a realistic training experience that will build skills that translate easily to the workplace. The Smart Process Plant also includes multiple experiments, which simulate both continuous and batch process control loops that are widely used in many process industries. These experiments include:

- Basic and Advanced Bioreactor Applications

- Clean-In-Place (CIP) Skid Application

- Boiler Drum Level Application

- Wastewater Treatment Application

With these experiments, learners will explore a wide variety of fundamental process control topics, including: temperature, level, flow, pressure, and pH ratio control; agitation; sequence control; continuous control; 3-element control; feed forward/cascade control; and pump lead/lag demand. The Smart Process Plant Training System is only one of DAC Worldwide’s many process control and instrumentation training systems. Visit DAC Worldwide online to learn more about its many other training systems!