Many manufacturing processes require the transfer of heat from one fluid (liquid or gas) to another, and most of those processes use heat exchangers to accomplish this task. In a heat exchanger, the two fluids do not make direct contact. Instead, heat passes from the hotter fluid to the metal isolating the fluids and then to the cooler fluid.

You’ll find heat exchangers in a wide variety of industrial applications, including heating, ventilation, and air conditioning (HVAC) systems; preheaters or coolers in fluid systems; radiators on internal combustion engines; and boilers, evaporators, and condensers used with fluids like oils, wastewater, hydrocarbons, biogases, etc. in industries such as oil and gas refining and power generation.

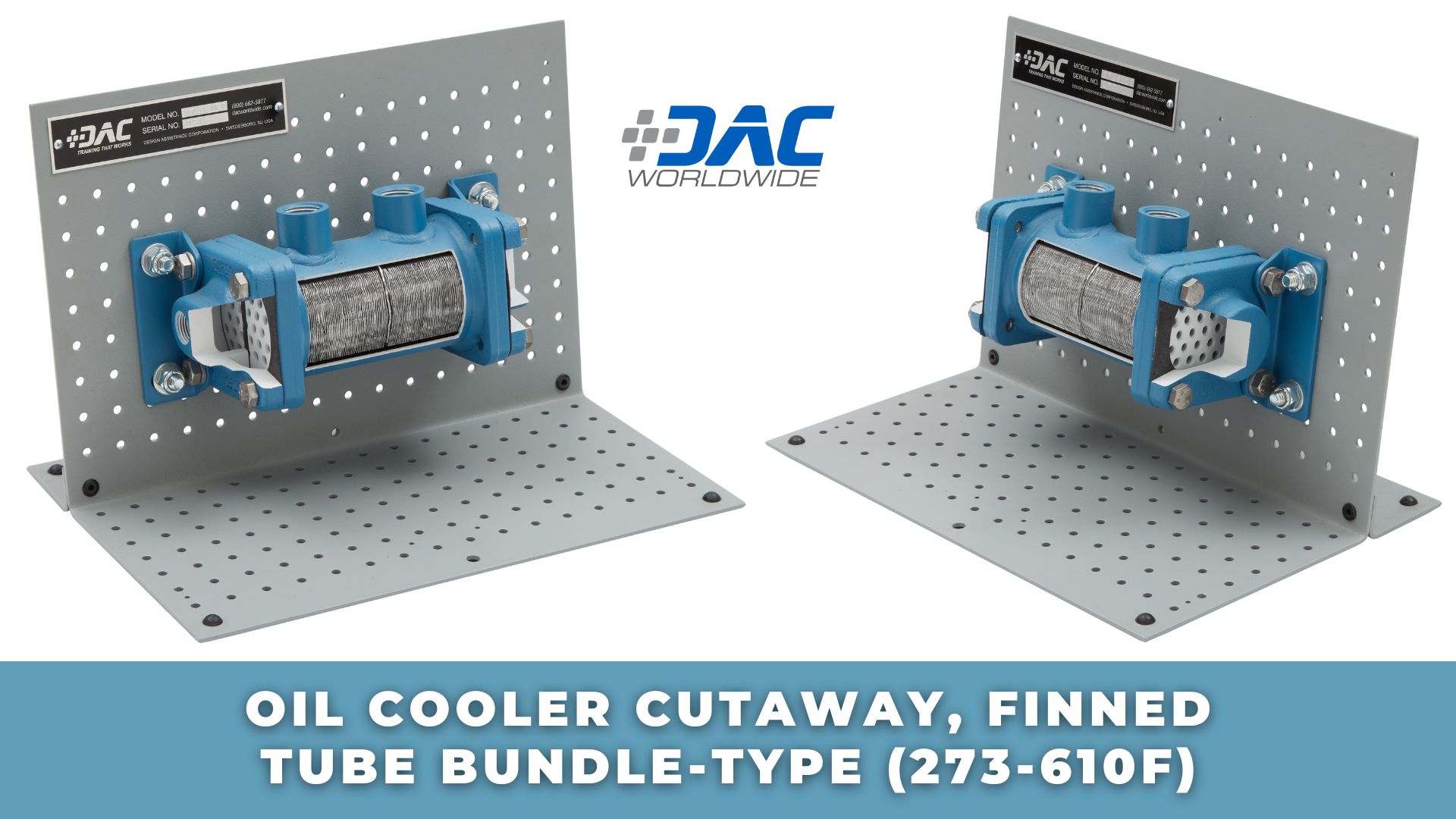

Heat exchangers come in a wide variety of shapes, sizes, and designs. For example, a finned tube oil cooler is a specific type of heat exchanger used to cool fluids, such as oil. A finned tube oil cooler features a bundle of tubes with fins that increase the surface area usable for heat transfer.

The tubes in a finned tube oil cooler can be made of a variety of materials, including aluminum, copper, or stainless steel. The fins are often made of the same material, although they can be made from another material, like carbon steel.

A finned tube oil cooler cools oil by circulating the oil through the tubes while water or another cooling fluid flows over the fins. The oil’s heat transfers from the fluid to the fins first and then to the cooling fluid, which transports the heat out of the system.

DAC Worldwide’s Oil Cooler Cutaway, Finned Tube Bundle-Type (273-610F) is a desktop training tool for industrial heat exchanger training that supports operations and skills training relating to this common device found in process systems of all types.

Finned tube heat exchangers have a wide variety of applications in the oil & gas, petrochemical, and power industries. These heat exchangers offer reliable operation, low operating costs, and high performance.

Oil coolers have some specific advantages. Oil has a higher boiling point than water, so it can be used to cool items 100°C or higher. In addition, oil is an electrical insulator, so it can be used inside of or in direct contact with electrical components.

Multiple cutaways unveil primary details and features, including tube layout, tube sheets, aluminum fins, nozzles, flow path, and gaskets. The cutaway consists of an actual industrial, 2-pass, heat exchanger/cooler. Common makes and models are chosen for industrial training relevance.

Mounted on a powder-coated, formed-steel mounting stand and allowing mounting on standard DAC Worldwide display and storage products, the device will provide years of use in any industrial training program.

DAC Worldwide’s Oil Cooler Cutaway, Finned Tube Bundle-Type is a professionally crafted, heavy-duty, durably coated, and fully detailed teaching aid that will provide years of service in the training lab or classroom. Be sure to check out DAC Worldwide’s website to explore a wide variety of other hands-on cutaways that feature the real-world components workers will encounter in the field!