Industrial machinery requires a wide variety of different types of motors to function efficiently and effectively. Whether they’re powering a compressor, pump, fan, or conveyor, three-phase induction motors keep operations at industrial facilities moving steadily.

Many induction motors require significant power given their heavy-duty applications. Moreover, they draw a high electrical current upon start-up. In fact, start-up current can sometimes be as much as 5-6 times what they draw at normal operating speed. This is why they require a special device called a motor starter.

If industrial motors relied solely on circuit breakers or fuses, those would trip or blow every time the motor started. That’s obviously unacceptable in an industrial setting. Instead, specialty motor starters start and stop induction motors using manual or automatic switches. They also protect motor circuits from excessive heat caused by overloads during normal operations.

Motor starters consist of two primary parts: (1) an electromagnetically operated set of contacts (called a contactor) starts and stops the motor by beginning or ending the flow of electrical current; and (2) an overload relay that protects the motor from drawing too much current and overheating.

Likewise, motor starters usually consist of two circuits: (1) a power circuit that transmits the primary voltage to the motor via the starter contacts and overload relay; and (2) a control circuit that manages the contactor coil that creates the electromagnetic field that operates the power contacts.

Because there are so many different types of industrial applications that require induction motors, there are likewise a wide variety of different types of motor starters. One common type is the reversing magnetic motor starter. Reversing starters, as their name implies, are specifically designed to efficiently reverse shaft rotation of a three-phase induction motor.

Reversing starters work by interchanging two contactors supplying electrical current to the motor, as well as having both a forward and a reverse starter. To ensure that only one of the starters can be engaged at any particular time, reversing starters feature both mechanical and electrical interlocks for enhanced safety.

Industrial maintenance technicians must be familiar with all sorts of induction motors and their motor starters. Hands-on training in electrical maintenance can elevate your technicians’ skills to the next level.

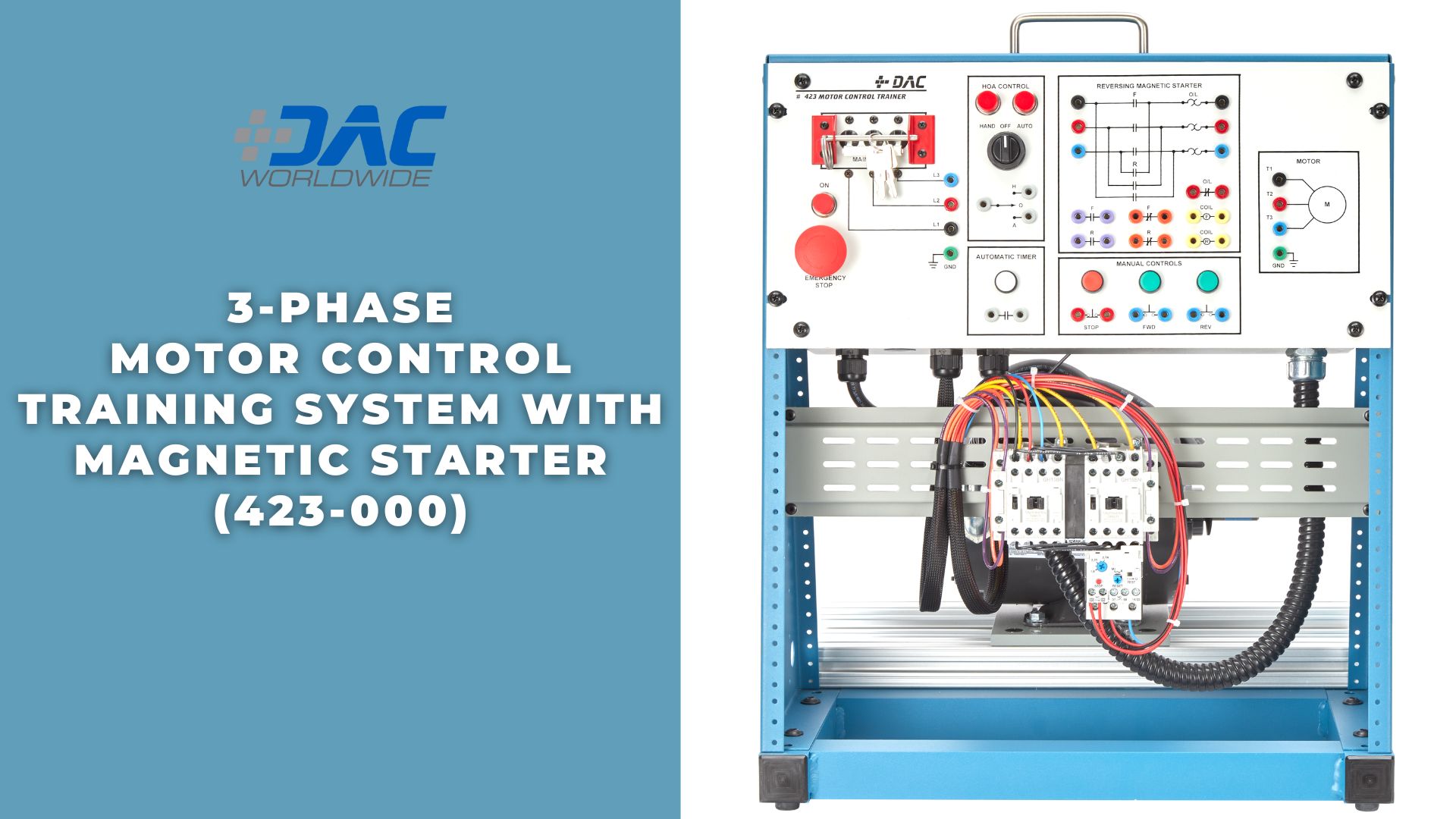

For example, if you want to ensure your maintenance technicians have the skills to work with reversing magnetic motor starters, DAC Worldwide’s 3-Phase Motor Control Training System with Magnetic Starter (423-000) offers comprehensive training in the operational principles, wiring, fault troubleshooting, and application of industrial three-phase, reversing magnetic motor starters.

The 3-Phase Motor Control Training System with Magnetic Starter is self-contained, allowing for individual study by a single student or a small student group. While often used independently, the training aid can be integrated with other optional products relating to programmable controllers, pilot devices, and motor-driven mechanical systems.

This electrical trainer includes a variety of industry-standard components, including: a three-phase induction motor; reversing magnetic motor starter with auxiliary contacts, mechanical and electrical interlocks, and overload relay; on-board wiring devices including Hand-Off-Auto (HOA) control station, manual control station, and automatic timer; color-coded, shielded banana-jack receptacles for all motor leads, supply connections, and control components; circuit breaker with lock-out/tag-out; keyed power switch; pilot light and emergency stop switch; and four instructor fault switches to create common component faults for troubleshooting instruction.

The 3-Phase Motor Control Training System with Magnetic Starter is only one of DAC Worldwide’s many electrical training systems. Visit DAC Worldwide online to learn more about other electrical training systems, such as the Three-Phase, Squirrel Cage Rotor, AC Motor Training System; 1-Phase Motor Control Training System with Manual Starter; DC Permanent Magnet Motor Control Training System; and many more!