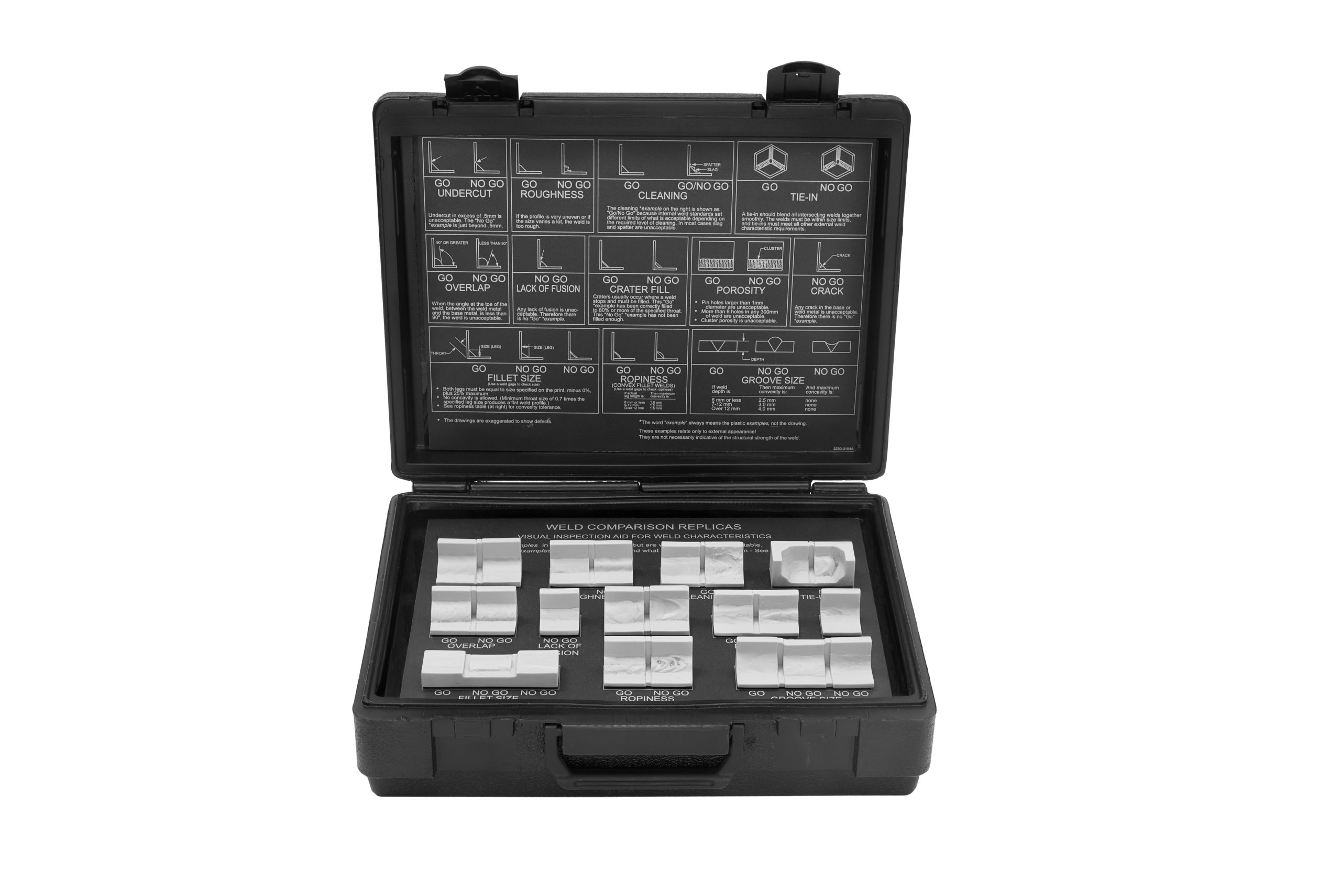

DAC Worldwide’s Weld Fault Comparison Kit (825-000) is a three-dimensional visual aid with accompanying training materials that facilitates basic training in weld quality and weld fault terminology by accurately depicting and identifying common weld defects. The set includes twelve molded weld samples. Each sample depicts acceptable (Go) and unacceptable (No Go) examples of common weld defects. The student establishes a system of consistent weld fault terminology and weld fault evaluation techniques, resulting in effective workplace communications and a visually-defined standard of quality.

Welding defects shown include undercut, tie-in, porosity, lack of fusion, fillet size, and other common faults.

Optional loose samples and a weld fillet gauge are available to expand the content, scope, and usefulness of the training system.

The courseware, useful in both an instructor-led or self-directed format, includes 3 hands-on exercises: 1) Introduction to basic weld joint terminology & identification; 2) Identification, rating, and classification of weld faults commonly found in the field; and 3) Introduction to the use of a weld fillet gauge.