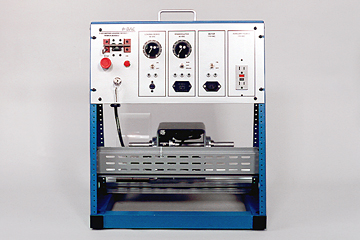

- Welded tubular aluminum base assembly with rubber support and vibration isolating feet.

- 16-Gauge, formed-steel support structure facilitating mounting of controls at a convenient and ergonomically-appropriate position.

- Provision for direct-mounting, without base assembly of frame on related DAC bench and workstation products, as well as on t-slotted electro-mechanical integration bench work surfaces.

- 1/8" Aluminum, powder-coated and silk-screened front panel face.

- Panel-mounted Electrical and control devices including master instructor key switch, mater circuit breaker with provision for lock-out/tag-out, pilot light, emergency stop switch, system GFI, with single-phase utility outlets, DC load control rheostat with relay control contacts allowing external control, brake/clutch assembly DC controller with indicating potentiometer control, and relay control contacts allowing external control, specialty single phase motor connector with relay control contacts allowing external control, component-proprietary connecting sockets.

- Full permanent internal grounding and cover removal safety interlock.

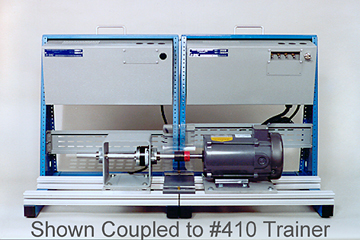

- Industrial electro-magnetic tensioning brake with 3/4" connecting shafting, with steel and aluminum mounting assembly, and dedicated connection cord.

- Coupling/Guard assembly, incorporating aluminum baseplate, polycarbonate guard, Lovejoy (JAW & Spider) coupling allowing for connection to related motor modules.

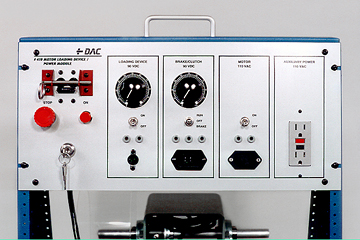

- Electro-Magnetic Tensioning Break

- Coupling/Guard Assembly

- Master Instructor Key Switch

- Circuit Breaker

- Pilot Light

- E-Stop System GFI

- DC Load Control Rheostat

- Brake/Clutch Assembly

- DC Controller with Potentiometer Control

- Requires 410-Series Motor Training System

DISCLAIMER: Product Dimensions are approximate. Shipping Dimensions and Weights are for directional use only and may change based on manufacturer variables. For the most accurate Shipping Dimensions and Weights, please contact the manufacturer.

- Approx. 19-in. L x 19-in. W x 25-in. H (480 x 480 x 640 mm)

- 50lbs. (23kg)

- 115V/60Hz/1ph