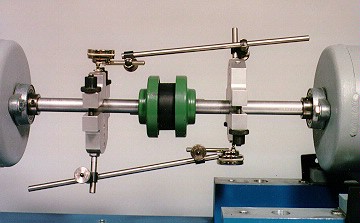

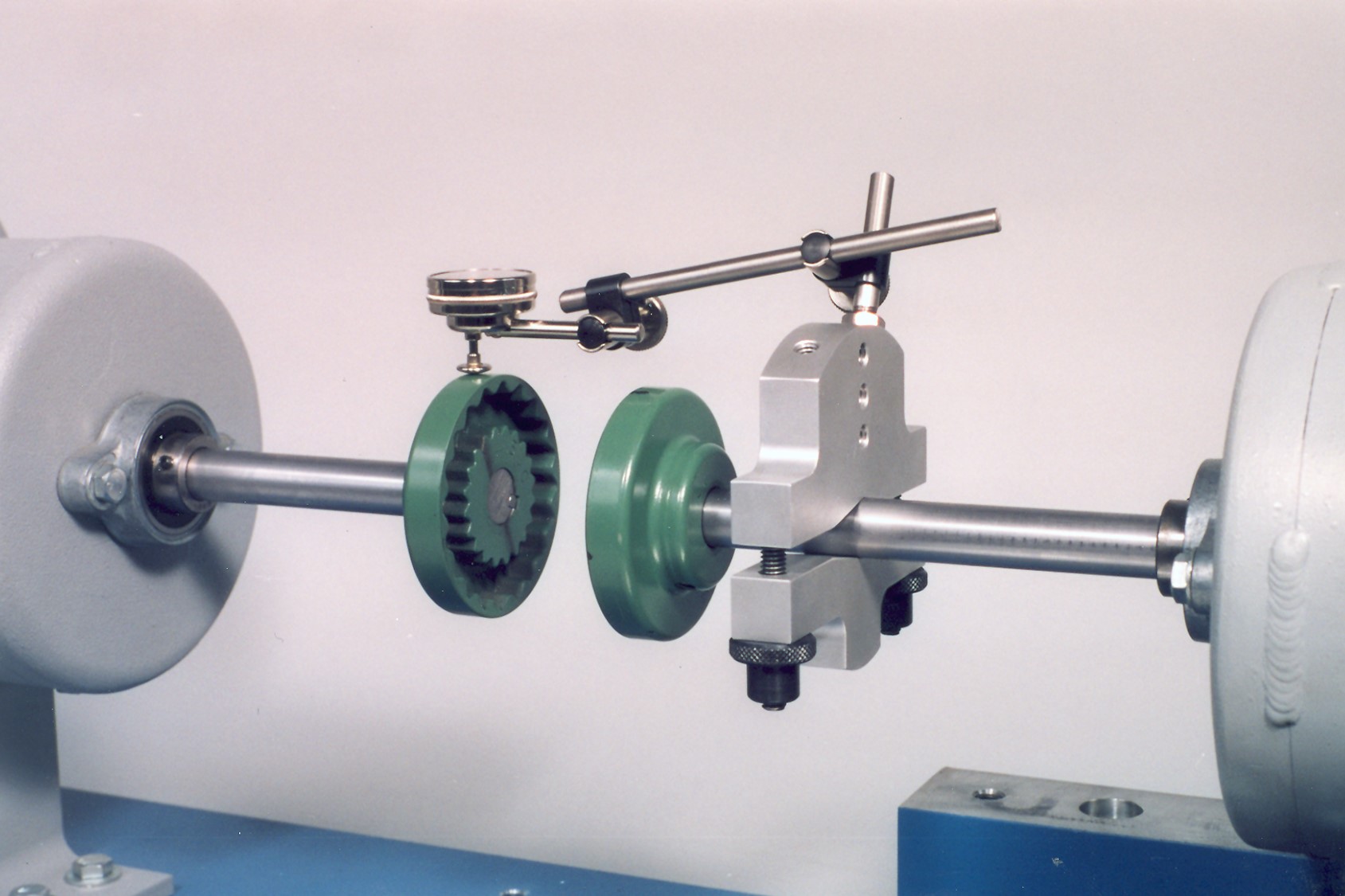

DAC Worldwide's Shaft Alignment Tool Kit (208-001) is a versatile, comprehensive tool kit that expands the teaching capabilities of several DACW products to include hands-on skills for precision coupling or shaft alignment using a wide variety of methods.

DACW's Shaft Alignment Kit includes:

- CNC-machined, aluminum shaft clamps

- Precision dial test indicators

- Assortment of related support rods and clamps. This mechanical drive shaft alignment training kit allows for assembly in a wide range of configurations.

Clamping components can easily be arranged to allow for both “rim and face” or “reverse dial” alignment on shafts from 0.5-in. diameter to 3.25-in. diameter. Multiple radial and longitudinal support rods are provided accommodating long-span and large-diameter applications.

The clamp set is packaged with associated tools commonly used when performing a precision alignment.

This mechanical drives shaft alignment kit can be used with DACW's 3-Component Coupling Shaft Alignment Training System (206-000), Vertical Coupling/Shaft Alignment Training System (207-000), and Coupling/Shaft Alignment Training System (208-000).