Important Product Note: Photographs are representative and for reference only. Product appearance and dimensions may vary based upon component manufacturer and availability. Any product dimensions given, such as size and weight, are approximate and for directional use only. For the most accurate shipping dimensions and weights, please contact the manufacturer.

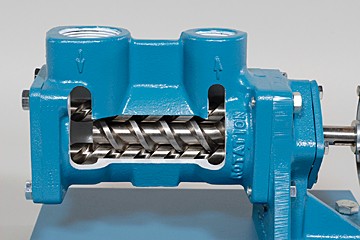

- Sectioning of an actual industrial diaphragm pump. (Manufacturers such as IMO and Leistritz are chosen for industrial relevancy)

- Cleaning, priming, and painting using a high-durability urethane coating

- Color-coding of cutaway surfaces, seal elements, and pumping surfaces using contrasting colors

- Replacement plated hardware, where necessary

- All gaskets, seals, and bearings visible

- 7-Gauge formed-steel baseplate, with provision for tabletop mounting or mounting on related DAC workstation and display products

- Crating for shipment via motor freight

DISCLAIMER: Product Dimensions are approximate. Shipping Dimensions and Weights are for directional use only and may change based on manufacturer variables. For the most accurate Shipping Dimensions and Weights, please contact the manufacturer.

- Product Dimensions

(L x W x H)

12in x 13.5in x 11in (305 x 343 x 279 mm) - Shipping Dimensions

(L x W x H)

15in. x 22in. x 24in. (381 x 559 x 609 mm)

- Recommended #903F Electromechnical Workstation (Extended)