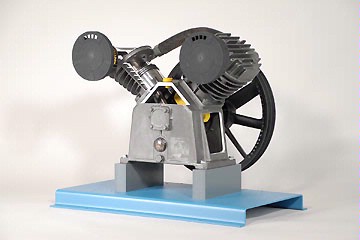

Important Product Note: Photographs are representative and for reference only. Product appearance and dimensions may vary based upon component manufacturer and availability. Any product dimensions given, such as size and weight, are approximate and for directional use only. For the most accurate shipping dimensions and weights, please contact the manufacturer.

- Sectioning of actual industrial hardware (common compressor makes and models chosen).

- Cleaning, priming, and painting using a high-durability polyurethane coating.

- Color coding of component parts, where applicable.

- Replacement, plated hardware, where applicable.

- 14-Gauge, formed-steel, powder-coated mounting stand with component attachment piers.

- Provision for mounting on related bench and workstation products.

- Packaging for shipment via motor freight.

- Product Dimensions

(L x W x H)

24in. x 13.5in. x 18in. (600 x 340 x 450 mm)

DISCLAIMER: Product Dimensions are approximate. Shipping Dimensions and Weights are for directional use only and may change based on manufacturer variables. For the most accurate Shipping Dimensions and Weights, please contact the manufacturer.

- Recommended #902F Electromechanical Workstation.