DAC Worldwide’s PID Controller Simulator Training System, Level Control (610-000) is a realistic process control training simulator that provides an in-depth introduction to industrial process control, using a simulated level control process application and an embedded generic process controller. The device, coupled with a comprehensive student manual, creates a complete, self-paced learning system that reflects realistic industrial and commercial applications.

This self-contained, tabletop training system provides for complete, realistic courses in instrumentation control within an economical and space-saving package. Useful within industrial training programs or in an educational setting, the PID Process Control Trainer will help make this fundamental part of instrumentation maintenance training more memorable and effective.

Practice Hands-On Instrumentation Skills for Various Applications

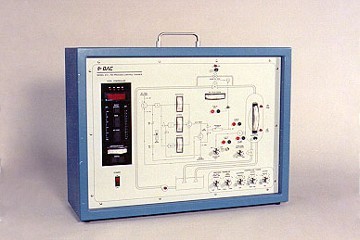

This PID Controller Simulator Training System utilizes a 16-gauge steel cabinet with carrying handles and realistic process control adjustments. The 16-gauge support frame provides durability to stand up to frequent use, and to aide learners in becoming better prepared for the tasks they will encounter on the job.

Analog gauges illustrate major sections of the common controller, including the proportional, integral, and derivative amplifiers. It also focuses on the manual output section, and illustrates their individual contributions to the controller output signal. Indicators allow the student to see the effect that a change in controller output has on final control element position and the process variable being controlled.

The device allows the controller to be tuned to provide proportional, proportional plus integral (reset), proportional plus derivative (rate), as well as proportional plus integral plus derivative control actions. Both open and closed loop tuning techniques can be used.

Additionally, control valve response time and process tank capacity can be adjusted. The device accepts and provides external 4-20mA DC control signals, allowing it to be interfaced with an actual process. Optional signal generators and strip chart recorders can be easily connected to take training to the next level.

The trainer also includes a primary 110 VAC and 60Hz/240 VAC power supply with banana-jack input and output connections, allowing for use as an actual controller and process instrument inputs.

Hands-On Exercises and Learning Activities Lead to Realistic Results

DAC Worldwide’s PID Controller Simulator Training System, Level Control also features exercises and learning activities that focus more on results and less on secondary academic background information. This comprehensive training system offers content in instrumentation principles, with individual learning activities provided in a self-paced or instructor-led format. The integrated course features multiple activities, all of which include background information on the topic, hands-on experiments, and related review questions.

The curriculum includes eight (8) units of activities relating to instrumentation components, application, and physical properties. Individual topics discussed within the course include controller operation, controller open-loop proportional control characteristics, open-loop proportional plus derivative control characteristics, notch method of closed-loop tuning, and much more!

Optional Student Training Manual Available to Enhance Learning

A copy of this course’s Student Training Manual is available with the training system. Sourced from the Exercises and Learning Activities, the Student Training Manual takes the technical content contained in the learning objectives, and combines it into one perfectly-bound book. If you would like to inquire about purchasing additional Student Training Manuals for your program, please contact your local DAC Worldwide Representative for more information.