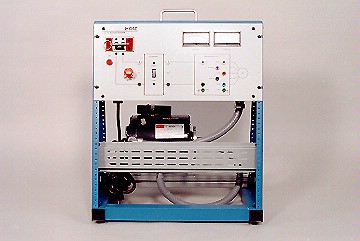

- Welded 1/8"-wall tubular aluminum baseplate assembly allowing for stand-alone tabletop use

- Provision for direct mounting of upper frame assembly and integration on related workstation, and integration bench products

- T-slotted aluminum motor and accessory mounting rails. (Allows for attachment of modular guard, and connection to optional adjacent accessories and other training aids)

- Commercial-duty 56Z frame PSC motor, with connection teather

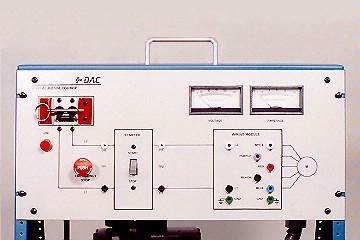

- Master circuit breaker with simulated lock-out / tag-out capability

- Silk-screened 1/8" aluminum front panel face with identification of line and motor lead numbers

- 16-gauge, formed-steel and powder-coated support structure and electrical enclosure

- Color-coded banana-jack patch cord receptacles

- On-board analog voltmeter and ammeter

- Permanent internal tamper-proof grounding of all elements for safety

- Enclosure front cover safety interlock (kill) switch

- Four instructor fault insertion switches (on rear of control enclosure)

- Large system emergency stop switch

- Keyed instructor power switch (on rear of control enclosure)

- Large pilot light and on-board manual motor-starting switch

- Use of UL and CE certified electrical components throughout

- Packaging for shipment via motor freight

- Product Dimensions

(L x W x H)

19" x 19" x 25" (475 x 475 x 630 mm)

45 lbs. (20kg) - Shipping Dimensions

(L x W x H)

20.75" x 23.75" x 30" (525 x 600 x 760 mm)

85 lbs. (38.5 kg)

110 VAC or 240 VAC, single-phase, based on destination country

- Patch cords

- Use/Exercise Guide

- Fault switch access tool

- Instructor and student wiring diagrams

- Related textbook (with purchase of four or more devices)

The courseware, useful in both an instructor-led or self-directed format, includes a textbook on motors and motor control, and twenty-one (21) illustrated, hands-on exercises.

Exercises include:

- Introduction to motor control terminology and construction

- Interpreting motor nameplate data

- Wiring the split-phase, capacitorstart AC motor

- Wiring the permanent split capacitor-start AC motor

- Wiring the three-phase, wye/star configured squirrel cage rotor AC motor

- Wiring the three-phase, delta configured squirrel cage rotor AC motor

- Introduction to troubleshooting

- Troubleshooting the split-phase, capacitor-start AC motor

- Troubleshooting the permanent split, capacitor-start AC motor

- Troubleshooting the threephase, wye/star configured squirrel cage rotor AC motor

- Troubleshooting the threephase, delta configured squirrel cage rotor AC motor

- Wiring the shunt-wound DC motor

- Wiring the Series-wound DC motor

- Wiring the compound, cumulatively-wound DC motor

- Wiring the permanent magnet DC motor

- Troubleshooting the shunt-wound DC motor

- Troubleshooting the series-wound DC motor

- Troubleshooting the compound, cumulatively-wound DC motor

- Troubleshooting the permanent magnet DC motor