Important Product Note: Photographs are representative and for reference only. Product appearance and dimensions may vary based upon component manufacturer and availability. Any product dimensions given, such as size and weight, are approximate and for directional use only. For the most accurate shipping dimensions and weights, please contact the manufacturer.

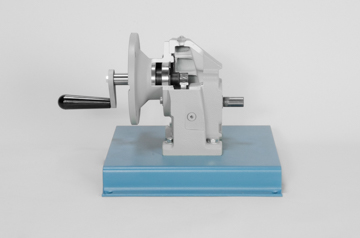

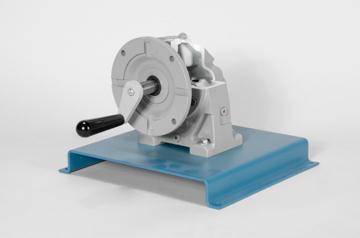

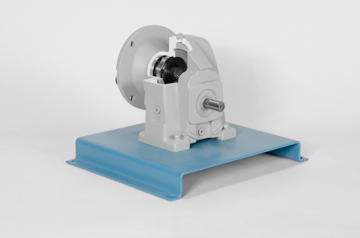

- 7-gauge, formed-steel baseplate with provision for bench-top, workstation, and storage rack mounting.

- Painting, where necessary, using a high-durability, urethane coating.

- Replacement hardware where necessary.

- Applicable installation and maintenance manual from original manufacturer.

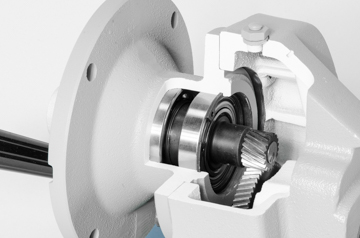

- Sectioning and restoration of actual industrial gear reducer. (Popular models by well-known manufacturers are chosen for industrial relevancy.)

- Simulated motion via hand crank.

- Packaging for shipment via courier or parcel service.

- Product Dimensions

(L x W x H)

13.5" x 18" x 11" (343 x 450 x 280 mm) - Shipping Dimensions

(L x W x H)

15" x 25" x 24" (381 x 635 x 610 mm)

DISCLAIMER: Product Dimensions are approximate. Shipping Dimensions and Weights are for directional use only and may change based on manufacturer variables. For the most accurate Shipping Dimensions and Weights, please contact the manufacturer.

- Recommended #902 – Electromechanical Workstation

- #510-000 - IPT Industrial Trades Training Manual

- #510-001 - IPT Industrial Trades Handbook

- #903 - Electromechanical Workstation, Extended

- #M205-01 - e-Learning: Introduction to Gear Drives

- #M205-02 - e-Learning: Types of Gears

- #M205-03 - e-Learning: Maintaining Gear Drives