According to the Occupational Safety and Health Administration (OSHA), lock-out/tag-out is one of the Top 10 "Most Serious Violations" and "Most Often Cited Violations" in the workplace. Lock-out/tag-out must be taken seriously, because workers maintaining equipment can be seriously injured from the unexpected energization of, release of stored energy from, or startup of equipment.

Lock-out/tag-out procedures establish standards for the shutdown of equipment, so that energy sources can be isolated to prevent the release of potentially-hazardous energy during routine maintenance activities. Following proper lock-out/tag-out procedures helps workers to avoid preventable workplace accidents and injuries.

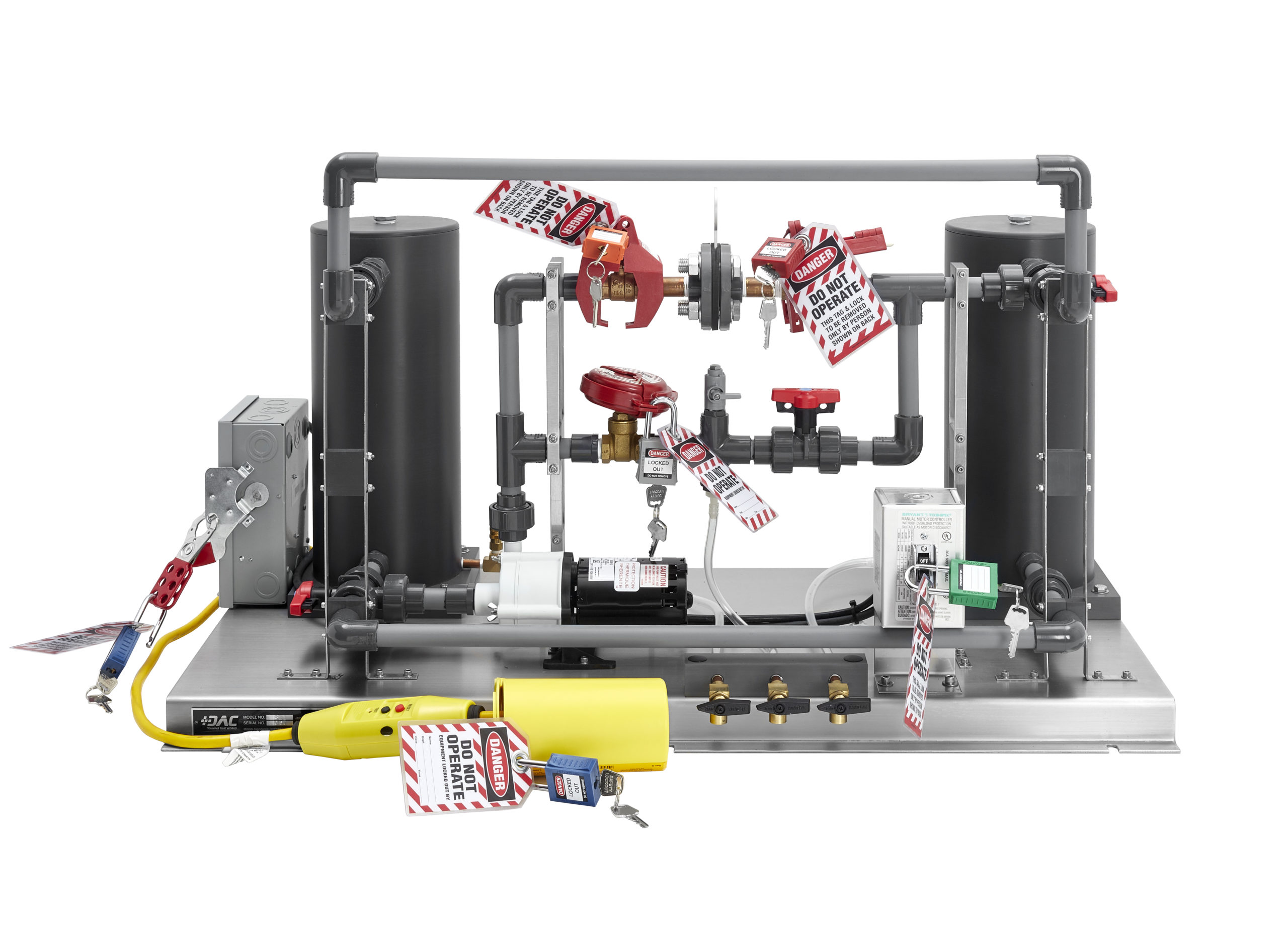

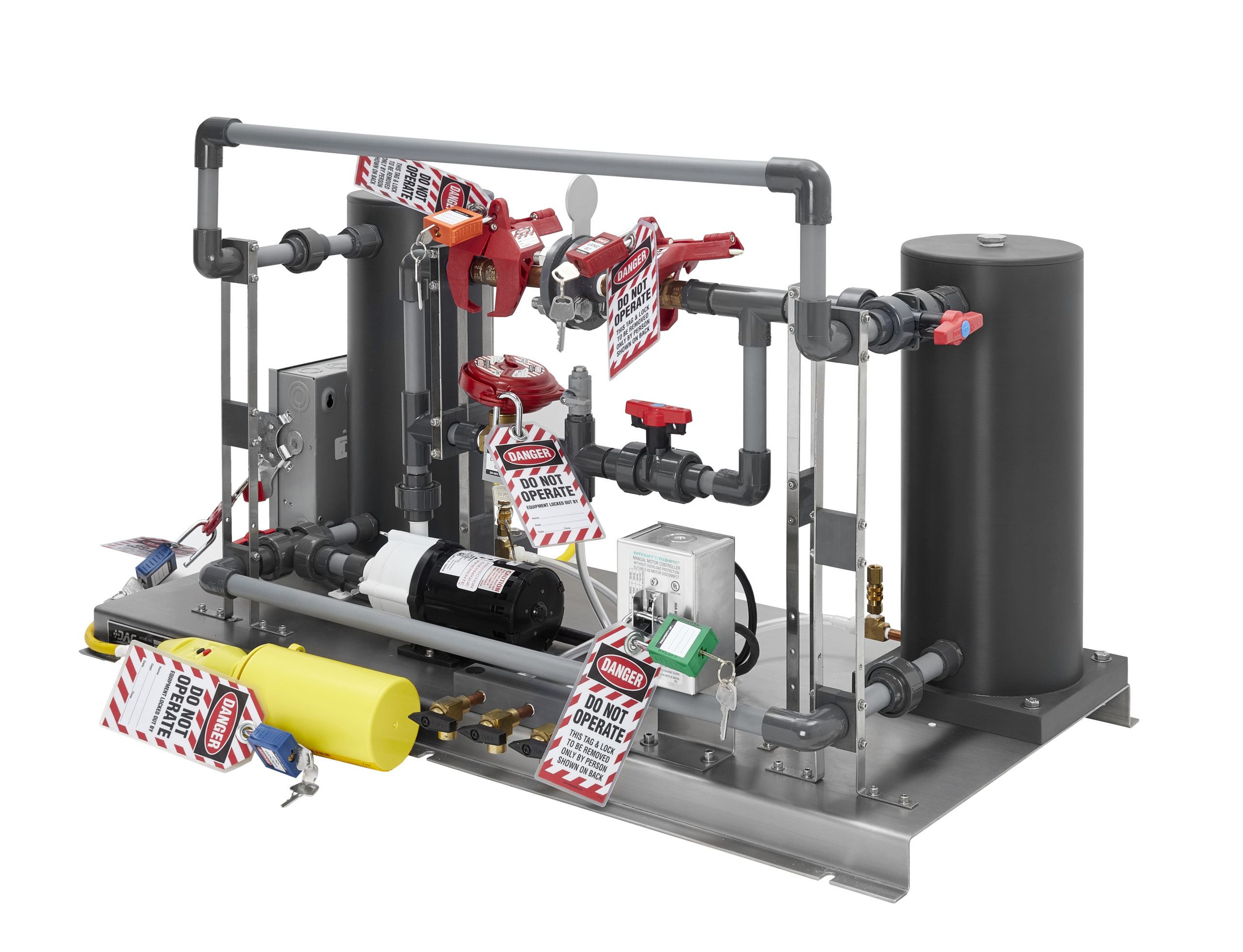

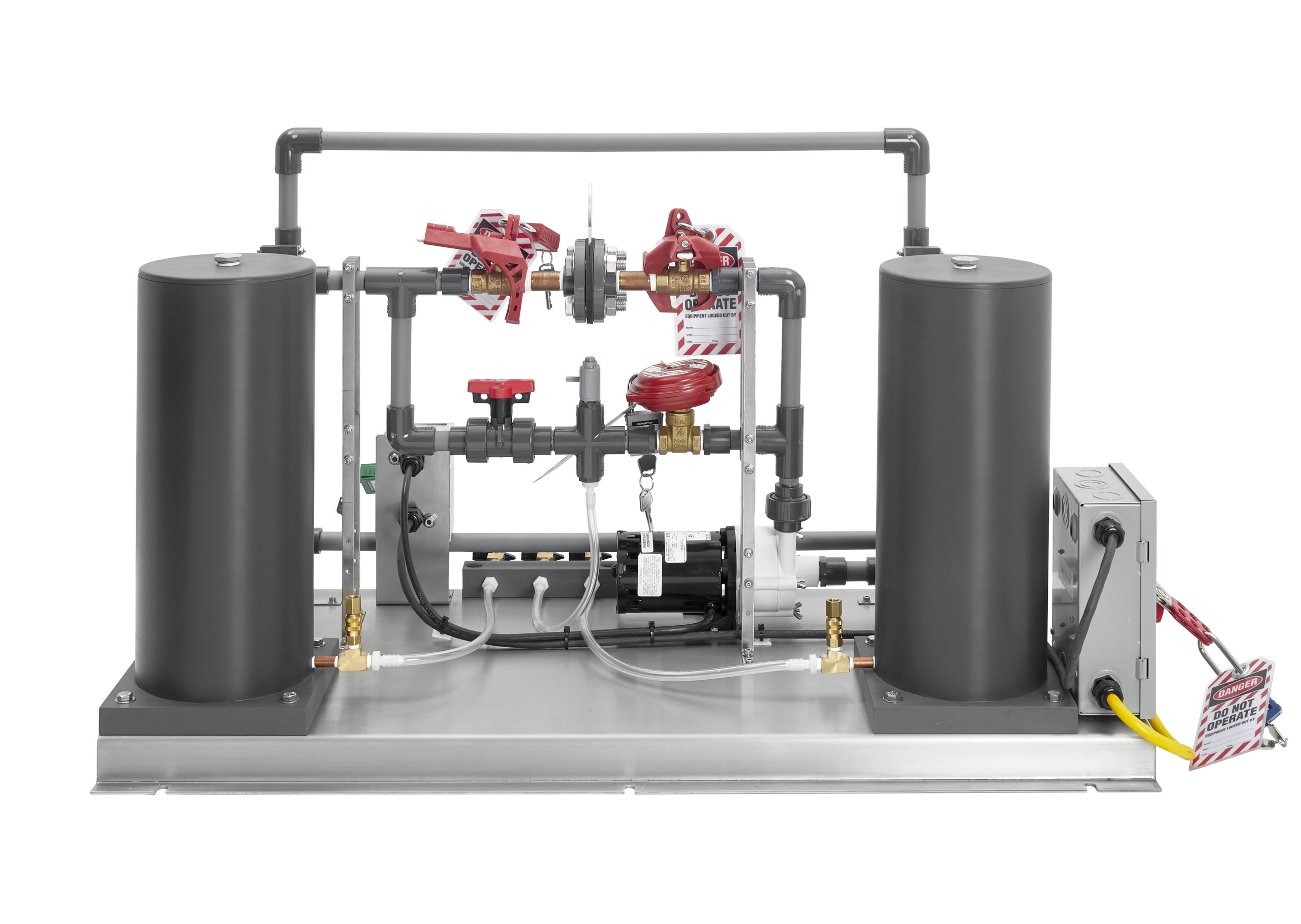

DAC Worldwide’s Lock-Out/Tag-Out Training System (811-000) features a realistic, simulated working process environment that facilitates introductory training with hands-on activities related to the process of identifying and locking out sources of dangerous potential energy in an industrial setting.

The training system includes two process tanks; a centrifugal pump; a complex, multi-purpose piping network; electrical controls; and a variety of lockable system components. A lock-out/tag-out kit that features a large number of commonly-encountered locking and tagging devices is also included.

Industry-Standard Components Provide Realistic, Hands-On Training

Technical training is most effective when learners can gain hands-on practice with industry-standard components they’ll encounter on the job. The Lock-Out/Tag-Out Training System features a wide variety of common, industrial-quality components to provide learners with a realistic training experience that will build skills that translate easily to the workplace.

For example, the Lock-Out/Tag-Out Training System features a wide array of industrial-quality components, such as: 2 PVC process tanks with removable covers, vents, drains, and process connections; PVC process network with block valves, 3-way valves, figure-8 blinds, and descriptive valve tags; fractional HP magnetic drive centrifugal pump; drain collection and distribution tubing network with valved central collection manifold; electrical controls, with provision for lock-out, including primary service disconnect, motor starter switch, in-line GFI protector, and system plug connection; and a comprehensive lock-out/tag-out tool kit with color-coded locks, tags, multi-lock hasps, specialty electrical locking devices, valve locking devices of multiple designs, and a dedicated toolbox.

Courseware & Hands-On Exercises

The Lock-Out/Tag-Out Training System’s courseware consists of a “Safety First” IPT Training Manual with a chapter on lock-out/tag-out, as well as hands-on exercises. These can be used as part of either an instructor-led course or self-directed study.

Learners will explore a wide variety of fundamental lock-out/tag-out topics. The course provides a strong foundation in general concepts and activities that will easily translate to the specific policies and procedures of individual companies and working environments.

The training system is designed to support individual and small team activities, as well as more complex, multi-discipline simulated activities. Learners will gain a strong foundation in the conceptualizing skills, planning, and detailed safe work practices needed to perform potentially-dangerous work activities in an industrial environment. A final performance assessment exercise is also provided, allowing the system to be used in an alternate configuration for testing purposes.