- Service requirements: electric - 110/240 VAC, 50/60Hz.

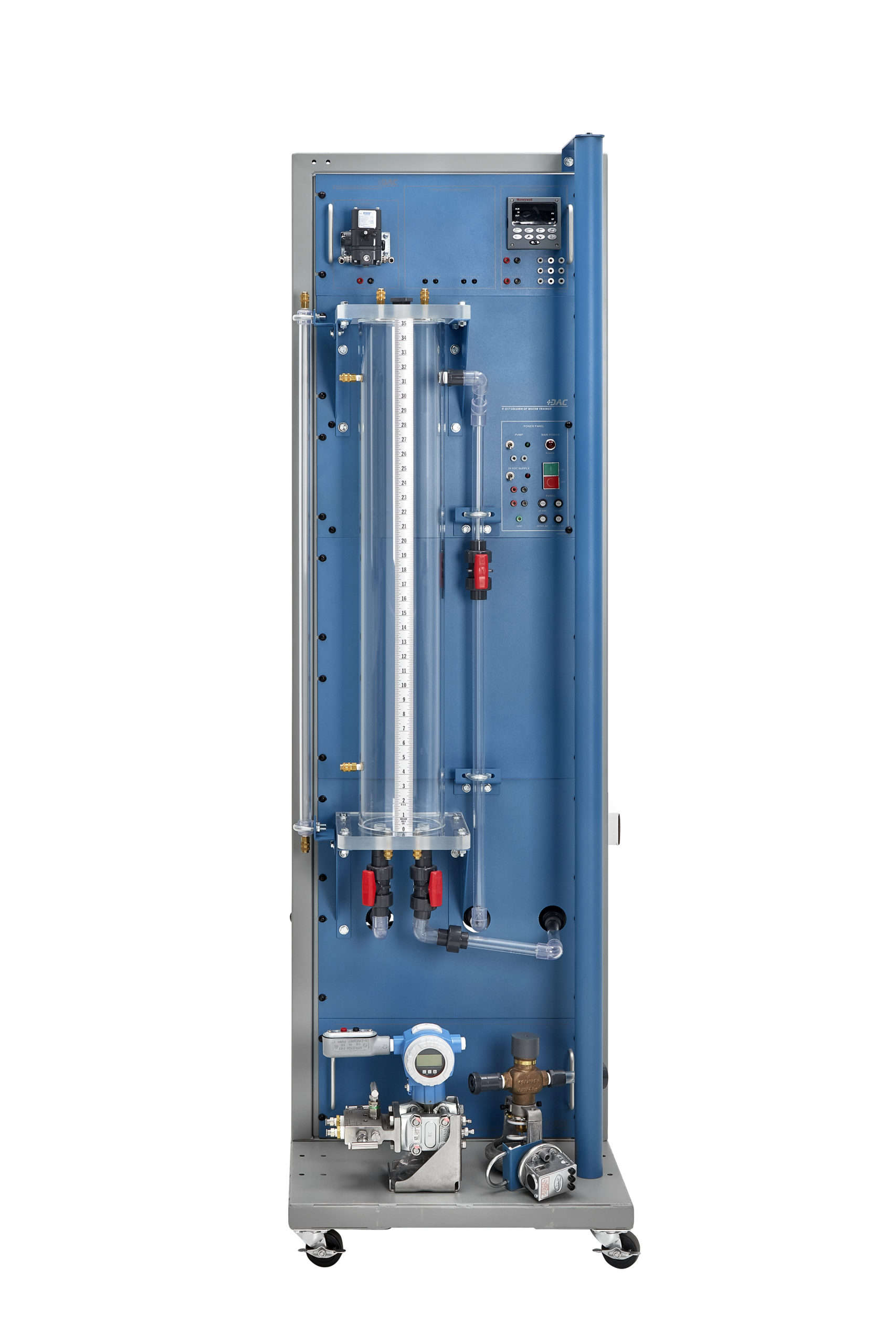

- Welded steel frame using 14-gauge 1-1/2" x 1-1/2" tube and 1/8" plate.

- Four casters two with locks.

- Front panel faces fabricated from 1/8" aluminum sheet.

- Clear, 1/2"-diameter, PVC piping and fittings throughout.

- Clear acrylic process tank, 3-gallon capacity.

- Wet leg demonstration tube fabricated from clear PVC pipe.

- Primary reservoir, 15-gallon capacity.

- Centrifugal pump, 1/4 HP, with inlet strainer.

- GFI circuit protection.

- Tank overflow protection.

- Power distribution panel/electrical enclosure mounted on 19" rack panel and including: on/off power switch, pilot light, fuses for all circuits, pump power switch with provision for external control via relay, 110/240 VAC service connections, and motor controller.

- 24 VDC power supply with banana jack connections.

- Quick-disconnect fittings located throughout, allowing for attachment of instruments, accessories, and optional equipment.

- Pipe stanchion, allowing for attachment of optional pressure gauges, pressure switches, differential pressure transmitters, and pressure transmitters at varying heights.

- 100' ¼”-diameter instrument connection tubing.

- Eight 36” test leads.

- Four 60” test leads.

- Eight quick-disconnect nipples.

- Six tubing tees.

- Six tubing couplers.

- Pressure gauge, 0-3 psig.

- Two 250 ohm conversion resistors.

- Use/Exercise Guide.

- Crating for shipment via motor freight.

DISCLAIMER: Product Dimensions are approximate. Shipping Dimensions and Weights are for directional use only and may change based on manufacturer variables. For the most accurate Shipping Dimensions and Weights, please contact the manufacturer.

- Product Dimensions

(L x W x H)

23in. x 34in. x 76in. (590 x 865 x 1930 mm)

195lbs. (89kg) - Shipping Dimensions

(L x W x H)

39-1/4in. x 27in. x 85in. (997mm x 686mm x 2159mm)

300lbs. (130kg)