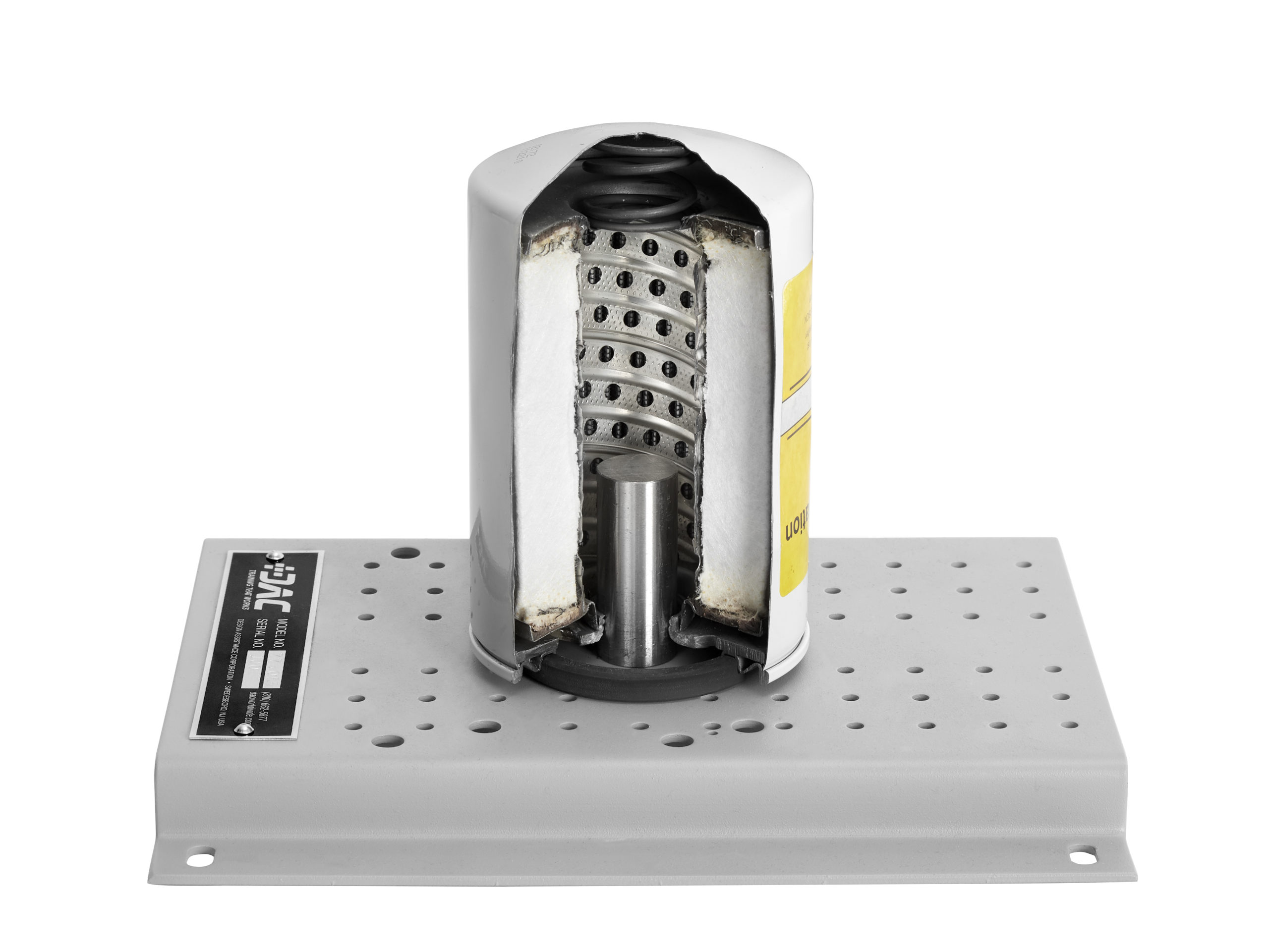

DAC Worldwide’s Hydraulic Filter Cutaway (773-055) is a professionally-crafted sectioned example of a commonly-encountered sump-type hydraulic filter used in hydraulic systems to maintain oil quality and machine health. The training aid enhances classroom training in hydraulic system design, maintenance, troubleshooting, and preventive/predictive maintenance.

Often encountered in both mobile hydraulic and embedded industrial systems, at or near reservoirs, and commonly in return lines, these critical hydraulic system components, are regularly replaced and inspected. The full-size, fully-detailed example gives learners a first-hand view into a component that is found in various applications worldwide.

This basic filter cutaway uses a large, commonly-encountered spin-on type hydraulic system filter from a well-known US manufacturer. The high-quality, high-pressure component is chosen for industrial relevancy and maximum visibility. Thanks to carefully planned sectioning, the complete internal configuration of this filter can be seen, while allowing for disassembly for more complete inspection and convenient classroom training in the operation, construction, and maintenance of these common pieces of hydraulic equipment.

Enhance Training with Hands-On Cutaway Industrial Components

This Hydraulic Pressure Gauge Cutaway provides a full cutaway view of the hydraulic filter body and cartridge area that exposes the complete internal design, flow path, seal, seat, spring, and sealing o-ring. Economically mounted on a formed-steel and powder-coated baseplate assembly, the product can be mounted on a variety of related optional display, storage and workstation products. This handcrafted teaching aid will support instructor-led training and independent student self-discovery in a variety of vocational and academic fluid power programs.

The cutaway features carefully-planned cutaway areas that are individually mounted, and possess the ability to be removed from the baseplate for convenient classroom use. All of the cutaway’s components are also visible and have been retained, enhancing students’ visual learning. Replacement hardware is provided where appropriate.

The equipment used within the cutaway is cleaned, primed and painted using a high-endurance urethane coating, providing durability to stand up to frequent use. In addition, all of the component parts are color coded to enhance the learning process.

Expand Training with Additional Hydraulic Model Options

The Variable Speed Belt Drive Component Cutaway is only one of DAC Worldwide’s expansive mechanical training cutaways, including a Hydraulic Pressure Gauge Cutaway (773-050), a Double-Acting Hydraulic Cylinder Cutaway (773-110), a Bladder Accumulator Cutaway (773-195), and more!