- One-piece, welded 1/8" wall tubular steel frame

- 3/16" steel mounting floor

- Four (4) 4" diameter casters, two (2) with locks

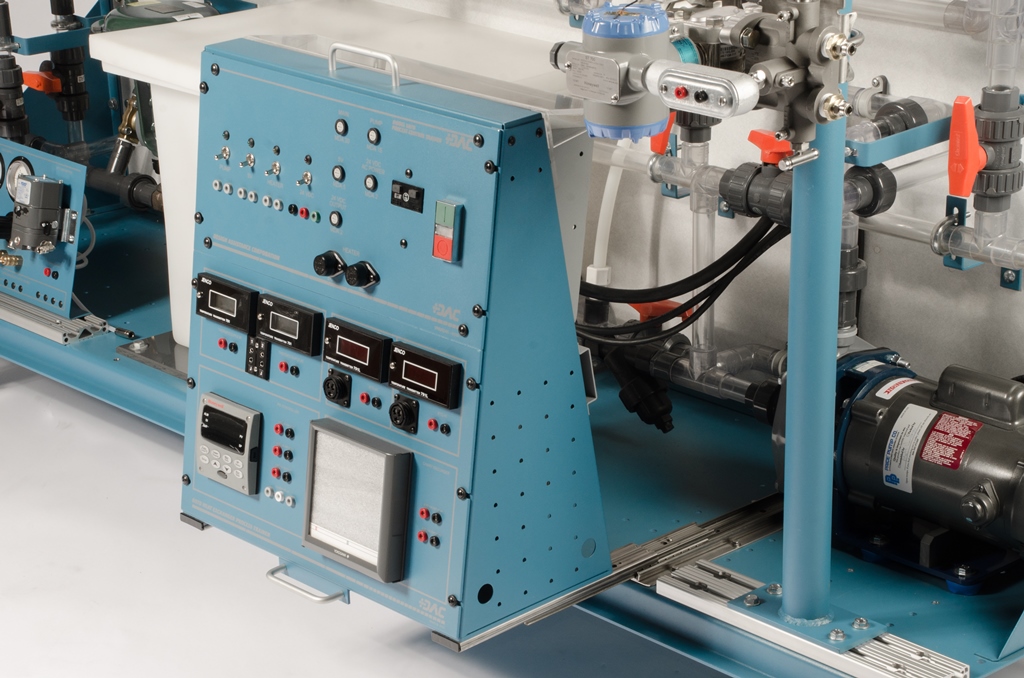

- Integral 19" x 70" high, instrument mounting rack with silk-screened instrument and controller panels

- Front panel faces fabricated from 1/2" MDF board and covered with a high-durability laminate

- 3/4" diameter CPVC and clear PVC piping components throughout

- Front panel-mounted operator control panel, includes switches and pilot lights for: pumps, solenoid valves, and immersion heaters, as well as control relay connections for equipment, 24 VDC power supply terminals and electric “free line” connections. A regulator with gauge controlling a 0-60 psi air supply with associated fittings and a second instrument air gauge with associated fittings is also mounted on this panel. An operator panel is also provided allowing for manual or semi-automatic operation, via contacts, of flow control solenoid valves.

- Master instrument air supply regulator

- Circuit breaker with GFI protection

- Two (2) variable-area flow meters

- Five (5) brass thermowells, facilitating temperature measurement at each heat exchanger

- Two (2) orifice flow assemblies with associated flanges and tubing connections

- Power distribution panel mounted in instrument rack, including on/off power switch, GFI receptacle, fuses for all primary circuits, and 12 electric “free line” connections to front panel

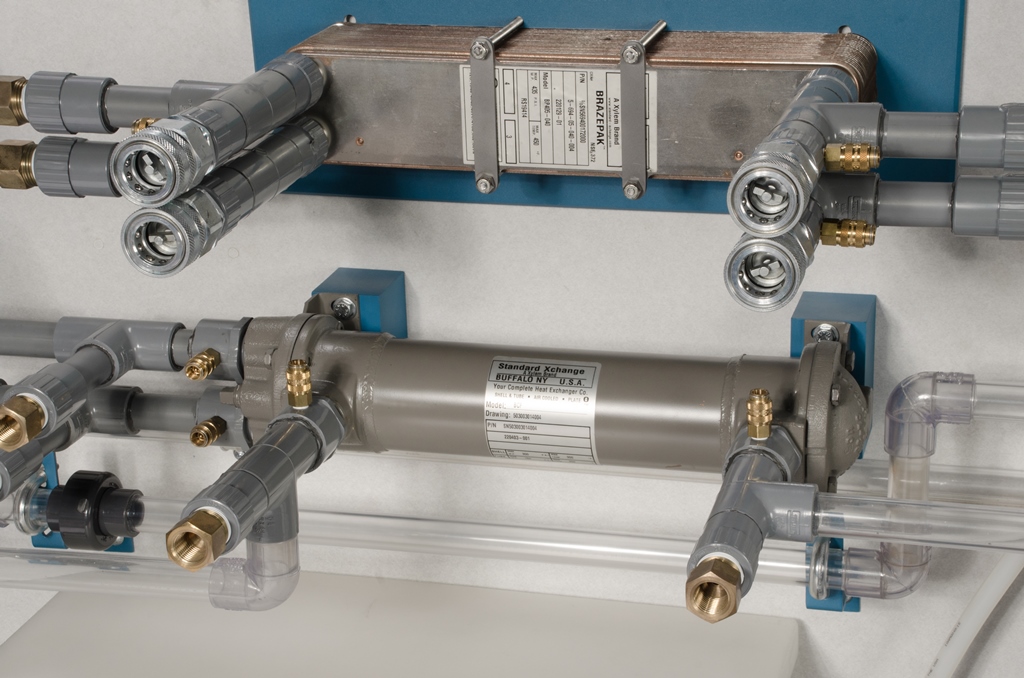

- Quick-disconnect fittings throughout, allowing for convenient attachment of instruments

- One diaphragm-type, industrial control valve

- One diaphragm-type, industrial, three-way control valve

- Multiple solenoid valves allowing for heat exchanger selection and concurrent/crosscurrent operations

- Four (4) thermowell-type bi-metal, thermometers

- Industrial-quality multi-pass shell and tube heat exchangers including: u-tube, single-pass, and multipass, straightflow varieties

- One plate-type heat exchanger

- Pipe stanchion, allowing for attachment of differential pressure transmitters and pressure transmitters at varying heights

- Primary reservoir - 20 gallon capacity - high-temperature polypropylene.

- Four (4) on-board digital thermometers with related RTDs, allowing for measurement at any location on the device

- Centrifugal pump, ½ HP

- Two (2) immersion-type heaters, 4 KW each

- 24 VDC Power supply

- Process quick-disconnect hose fittings, allowing for connection to other process control trainers

- Packaging for shipment via motor freight

DISCLAIMER: Product Dimensions are approximate. Shipping Dimensions and Weights are for directional use only and may change based on manufacturer variables. For the most accurate Shipping Dimensions and Weights, please contact the manufacturer.

- Product Dimensions

(L x W X H)

33.5in x 48in x 76in (860 x 1210 x 1930 mm)

425 lbs. (193 kg) - Shipping Dimensions

750 lbs. (340 kg)

- 208/230 VAC, 3-phase, 5 wire, 60 Hz OR 220 VAC, single-phase, 50 Hz,

- City water

- Floor drain

- Other electrical configurations are possible

- Twenty (20) 36" test leads

- Twenty (20) 60" test leads

- 150', 1/4" Diameter instrument connection tubing, of two colors

- Fifteen (15) quick-disconnect nipples

- Four (4) Bi-metal Thermometers

- Ten (10) tubing tees

- Ten (10) tubing couplers

- Orifice plate set, 3-piece

- Use/Exercise Guide