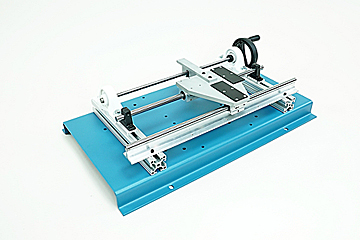

- Steel baseplate with two (2) aluminum, t-slotted mounting rails for component mounting

- Two (2) 1/2" Diameter ground steel shafts with provision for mounting on t-slotted support rail and on Thompson Industries, type-SB support blocks

- Two (2) closed-type linear bearing blocks (adjustable)

- One open-type linear bearing block (adjustable)

- Provision for adjusting bearing pre-load

- Provision for shimming and shaft paralleling activities throughout

- Provision for installation of shaft seals (wipers)

- Aluminum sliding carriage, allowing for mounting of linear bearings and ball screw drive nut

- 3/8" Ball screw with adapter for demonstrating axial movement

- Drive nut with provision for mounting on sliding carriage

- Drive handle

- Allows demonstration of four rotary-to-linear motion drive arrangements

- Packaging for shipment via motor freight

DISCLAIMER: Product Dimensions are approximate. Shipping Dimensions and Weights are for directional use only and may change based on manufacturer variables. For the most accurate Shipping Dimensions and Weights, please contact the manufacturer.

- Product Dimensions

(L x W x H)

24in. x 12in. x 6in. (610 x 305 x 150 mm)

33lbs. (15kg) - Shipping Dimensions

(L x W x H)

28in. x 15in. x 24in. (720 x 380 x 610 mm)

55lbs. (25kg)

-

Fixture for establishing shaft parallelism and leveling (accommodates dial indicator)

-

Dial indicator

-

Dial indicator support fixture, low-profile

-

Level

-

Allen wrench set

-

Combination wrench

-

Shim selection

-

Thompson Industries catalog