- For use with #203E - Extended Vibration Analysis Training System

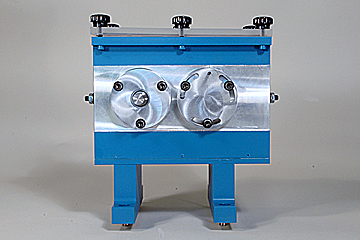

- Welded and re-machined modular aluminum gearbox, with provision for mounting on related product mounting surfaces via raised support feet with alignment pins

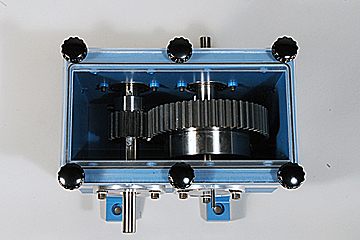

- Clear acrylic viewing and access safety cover, with locking knobs

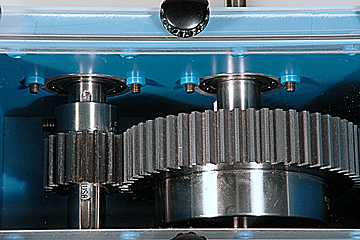

- Two (2) Helical gear sets, 12-pitch, 4 total

- Two (2) Spur gear sets, 10-pitch, 4 total

- One (1) Load/Brake Device

- Four custom bearing housings/caps of two designs allowing installation of deep groove ball bearings on the fixed input shaft and on the variable-position output shaft

- Provision for adjustment of output shaft centerline position, allowing for modified mesh patterns

- Machined steel precision input and output shaft set, with keyways, and keys

- Connecting helical beam coupling

- Disc brake-type mechanical load device, allowing operation of gear set under load. Includes machined steel disk, manual adjustable brake calliper, and mounting bracket

- 8-in. L x 6.5-in. W x 8.5-in. H (200 x 165 x 215 mm)

- 15 lbs. (7 kg)

For use with 203E Extended Vibration Analysis Training System