- Service requirements: electric - 110 VAC. Alternate voltage, phase, and cycle requirements are possible.

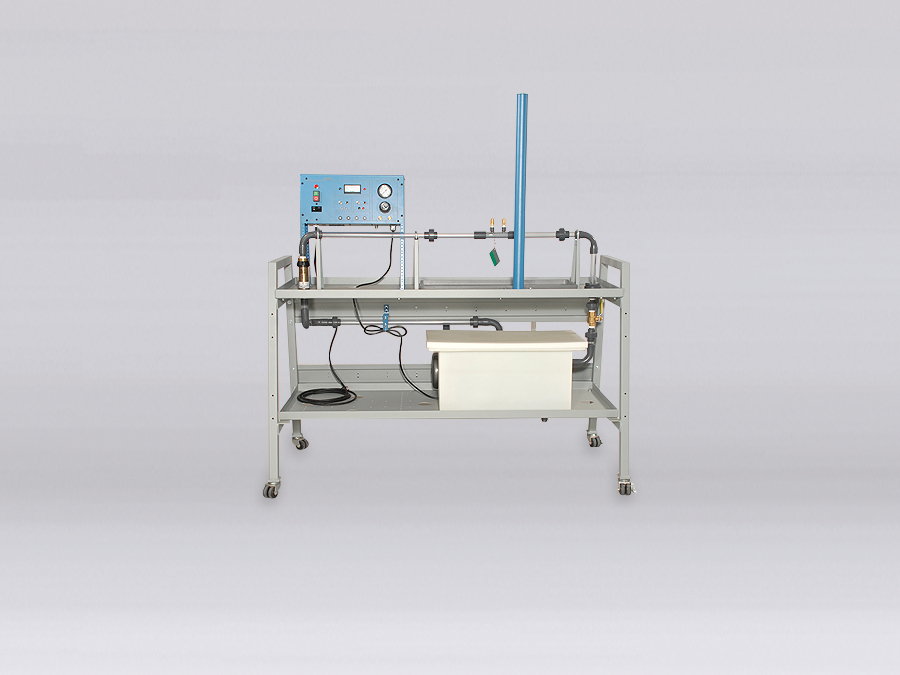

- Welded steel frame workstation using 14-gauge, 1-1/2" x 1-1/2" tube and incorporating two 14-gauge support shelves.

- Four casters, two with locks.

- T-slotted aluminum instrument stanchion mounting rails.

- Clear, 3/4"-diameter PVC piping and fittings throughout.

- Brass metered ball valve.

- Variable-area flow meter.

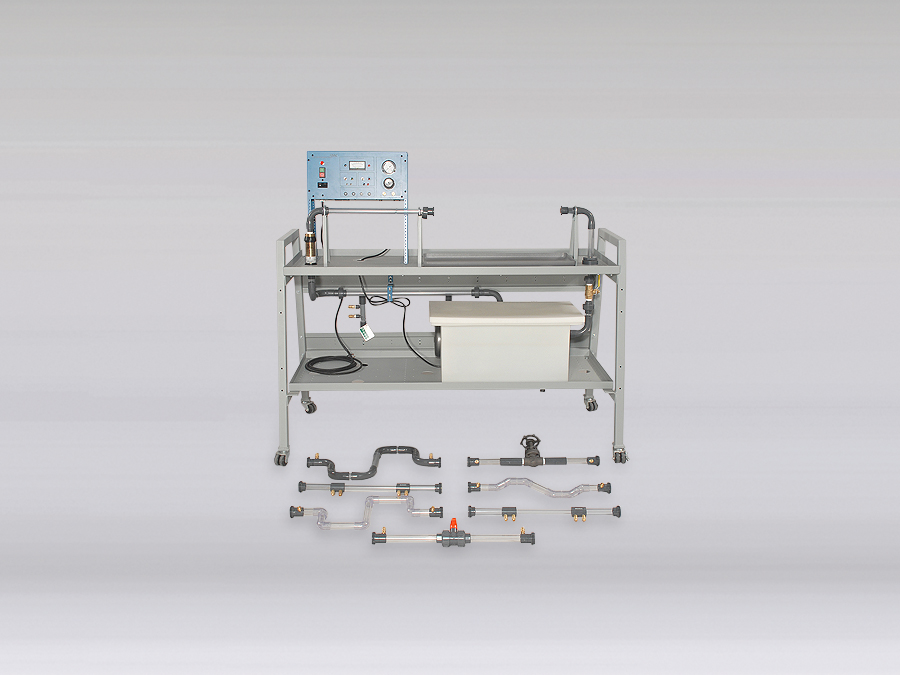

- Removable 24" pipe spool allowing for installation of standard flow apparatus, as well as optional flow instruments.

- Pitot tube flowmeter spool with tubing quick-connect fittings.

- Orifice plate flowmeter spool with tubing quick-connect fittings.

- Venturi tube flowmeter spool with tubing quick-connect fittings.

- Pipe spool storage rack.

- Control/power assembly including 19" rack-mounted control panel, steel support frame, and electrical enclosure.

- Panel-mounted components, including: pilot light, on/off switch, pump control switch with contacts for remote operation, GFI circuit protection, fuses, process meter with mA input, pressure regulator, pressure gauge, and air quick-connect couplings.

- Pump motor starter.

- 24 VDC power supply with banana jack connections.

- Primary reservoir, 15-gallon capacity.

- Pipe stanchion, allowing for attachment of differential pressure transmitters and pressure transmitters at varying locations and heights.

- High-durability, powder-coated surfaces throughout.

- 100 ¼”-diameter instrument connection tubing of two colors.

- Six quick-disconnect nipples.

- Six tubing tees.

- Six tubing couplers.

- Three orifice plates.

- Use/Exercise Guide.

- Crating for shipment via motor freight.

DISCLAIMER: Product Dimensions are approximate. Shipping Dimensions and Weights are for directional use only and may change based on manufacturer variables. For the most accurate Shipping Dimensions and Weights, please contact the manufacturer.

- Product Dimensions

(L x W x H)

63in. x 24in. x 40in. (1600 x 600 x 1275 mm)

255lbs. (116kg) - Shipping Dimensions

325lbs. (147kg)