Important Product Note: Photographs are representative and for reference only. Product appearance and dimensions may vary based upon component manufacturer and availability. Any product dimensions given, such as size and weight, are approximate and for directional use only. For the most accurate shipping dimensions and weights, please contact the manufacturer.

- Component selected for industrial relevancy from well-known manufacturers

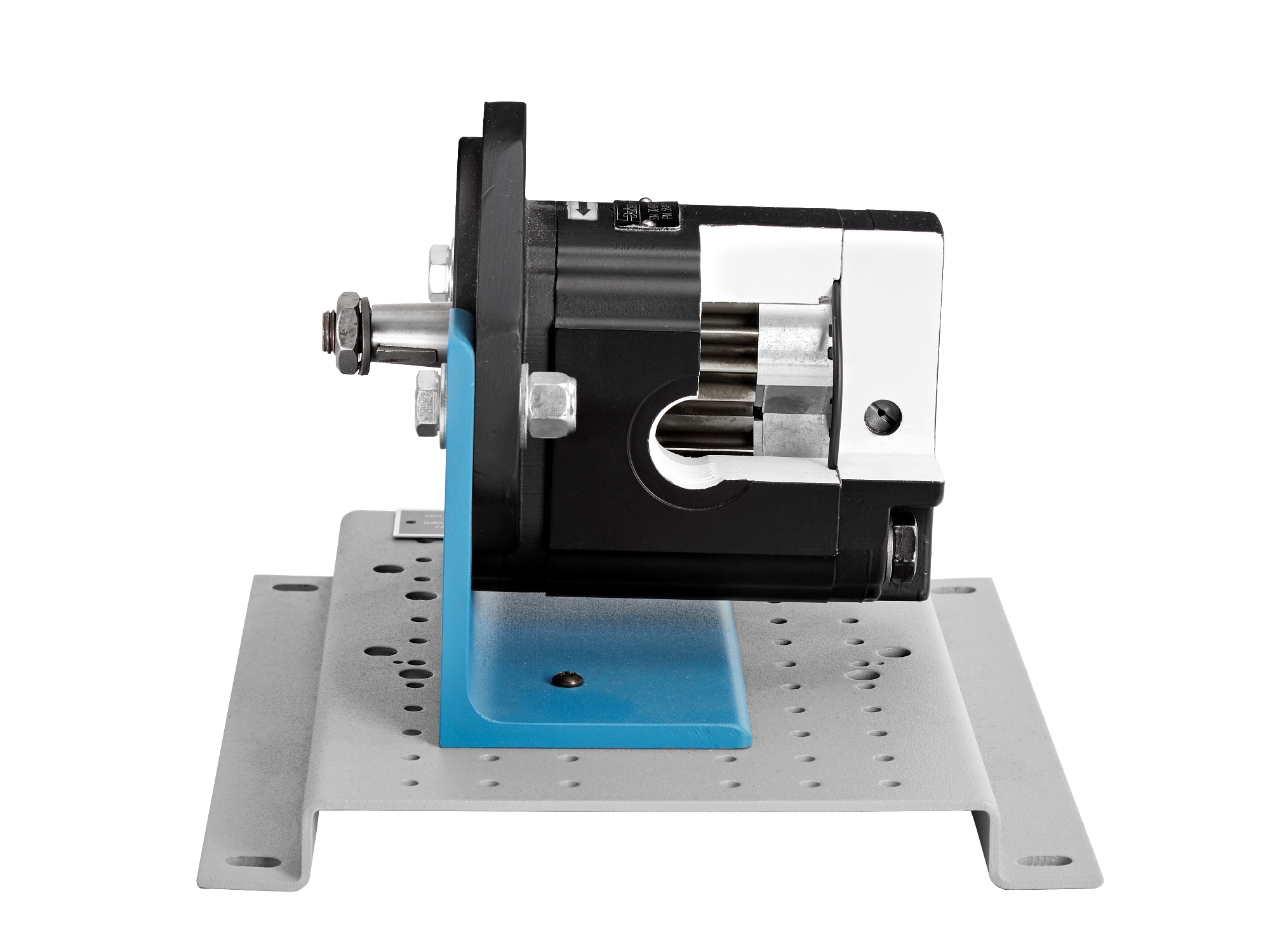

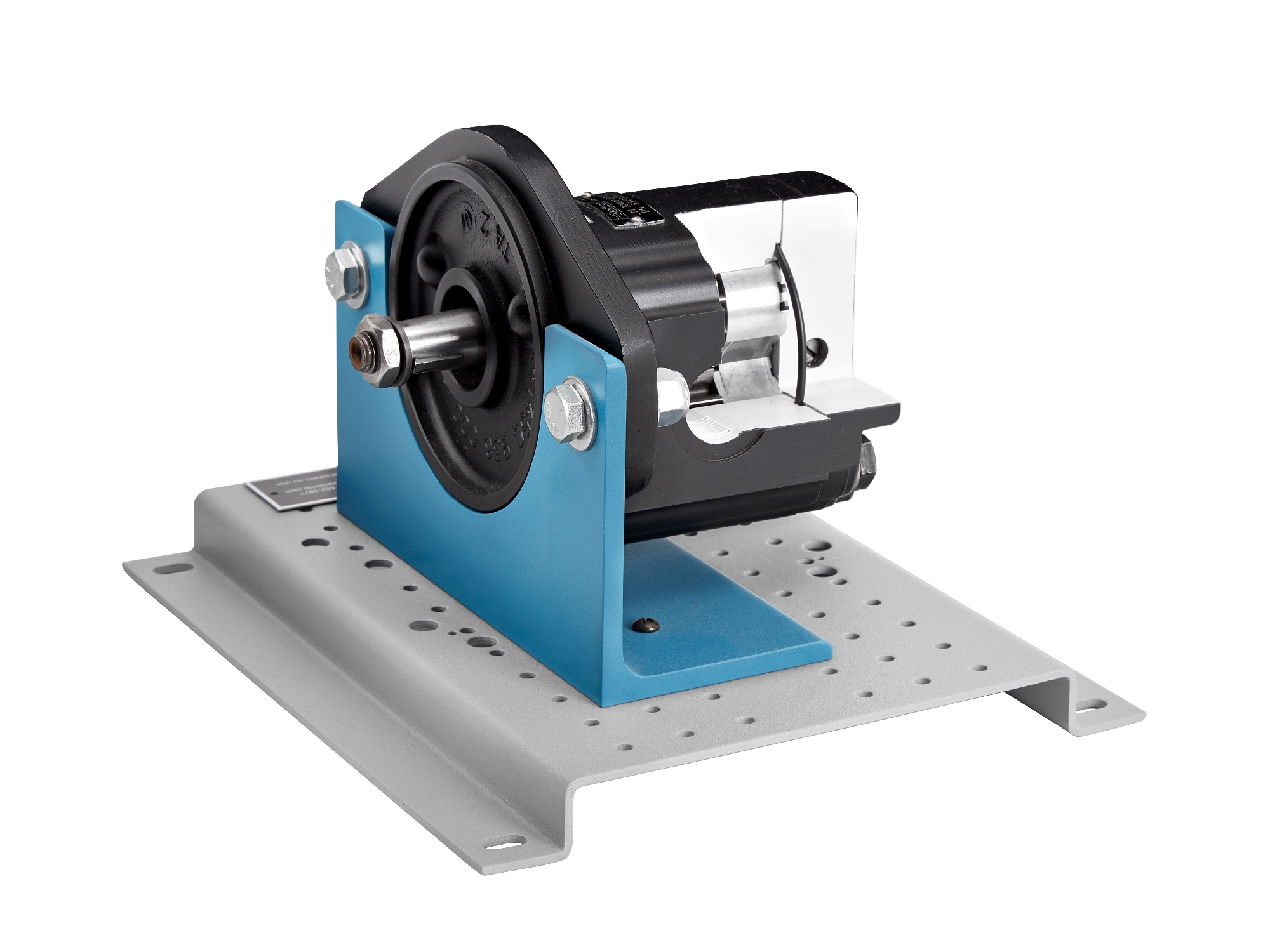

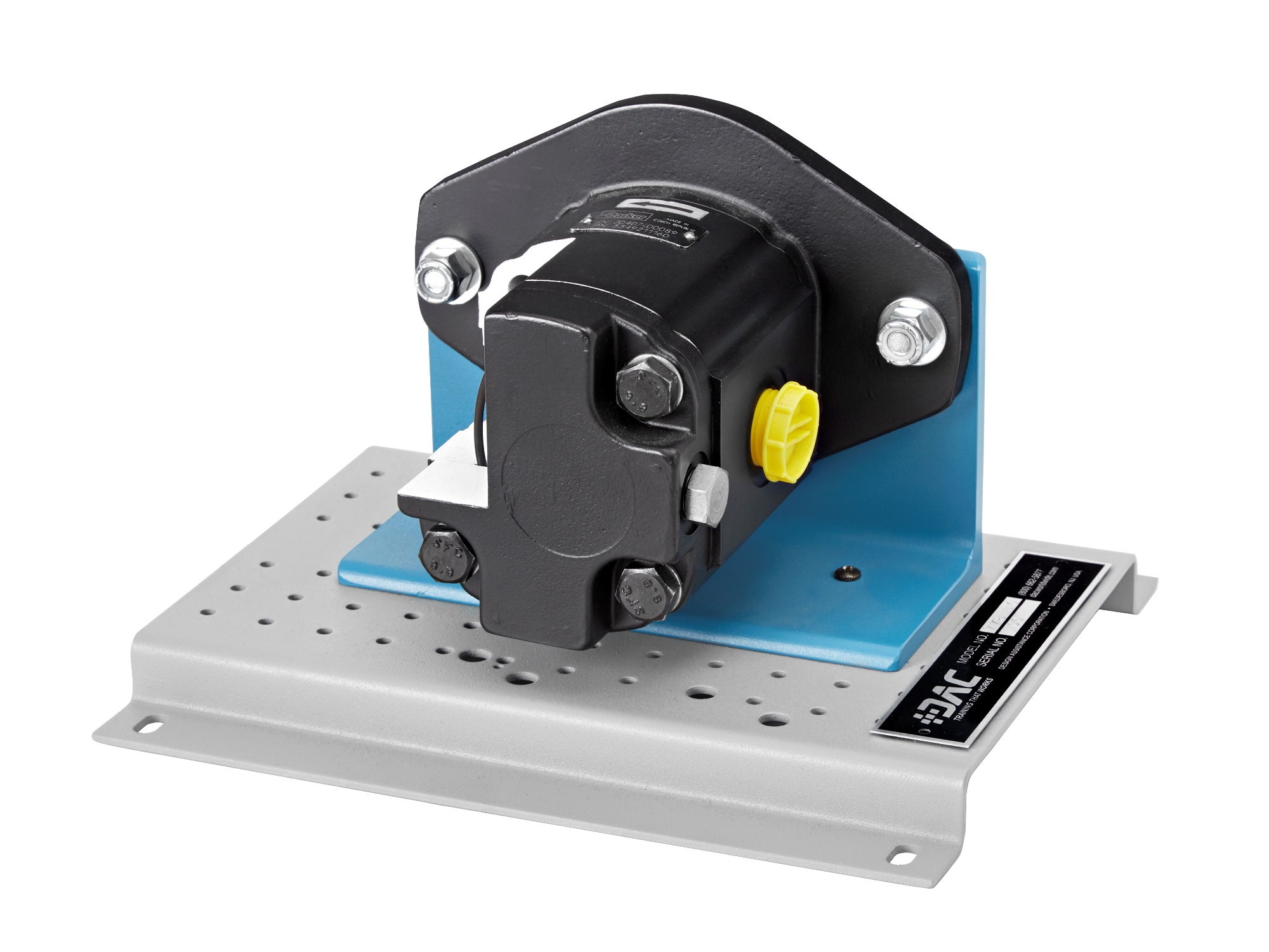

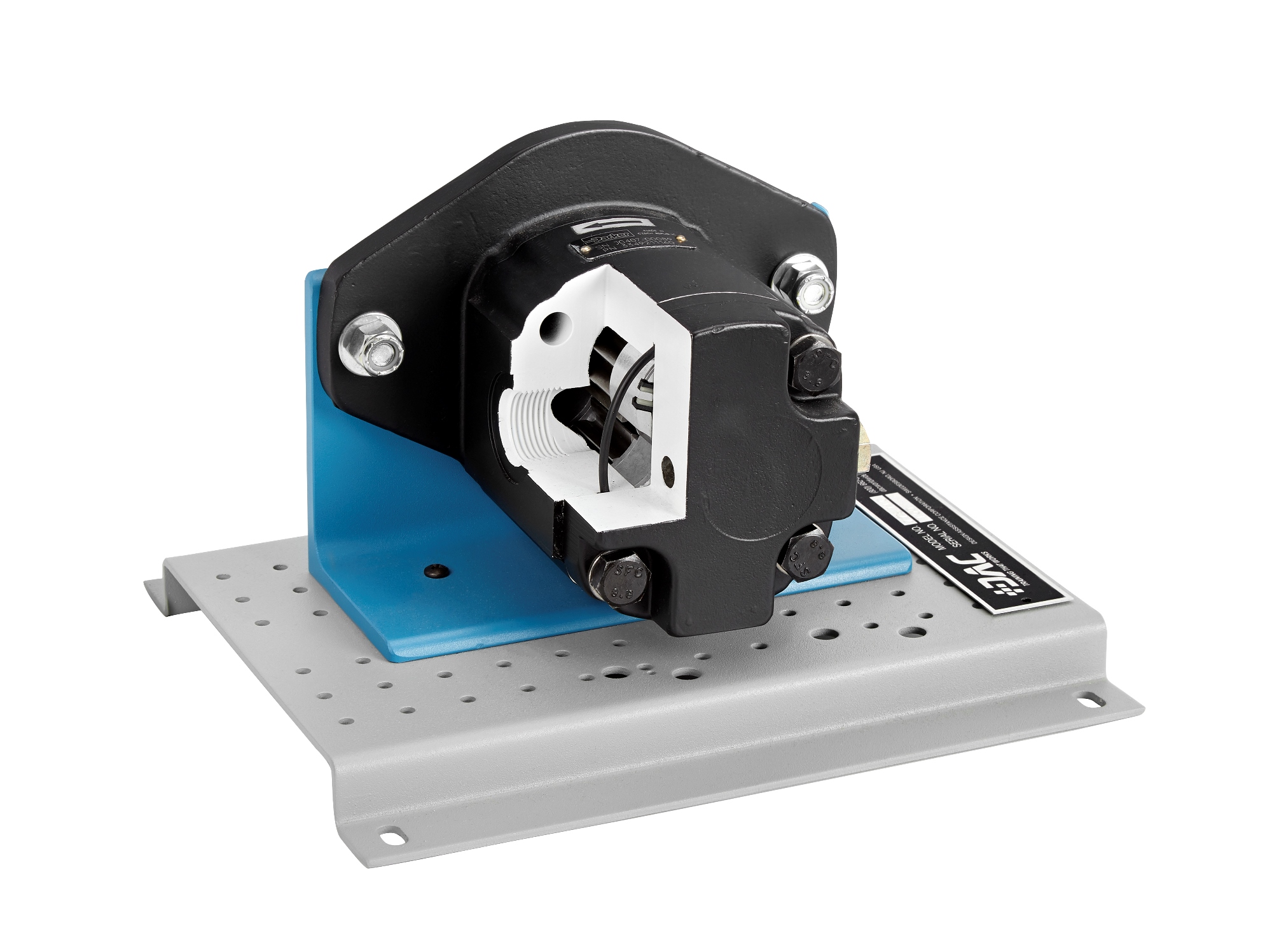

- Full component cutaway unveiling flow path, internal components, and operating principle

- Powder-coated 13-gauge formed-steel mounting bracket allowing for independent support/display or mounting on specialized optional steel mounting baseplates and display structures

- Refinishing of external surfaces, if warranted, using a high-durability urethane coating

- Durable membrane-type, adhesive-backed identification label with component description and symbol

- Provision for mounting on related optional, display, and storage structures

DISCLAIMER: Product Dimensions are approximate. Shipping Dimensions and Weights are for directional use only and may change based on manufacturer variables. For the most accurate Shipping Dimensions and Weights, please contact the manufacturer.

- Product Dimensions

(L x W x H)

9" x 9" x 9" (230 x 230 x 230 mm) - Shipping Dimensions

(L x W x H)

12" x 12" x 12" (305 x 305 x 305 mm)

Recommended 902V Mobile Display Stand